Metalized film for film capacitor

A metallized film, film capacitor technology, applied in the field of capacitors, can solve the problems of inflammability, impact resistance, high temperature resistance and weather resistance, affecting the quality of capacitors, operating temperature and service life, etc., to improve thermal conductivity. rate, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

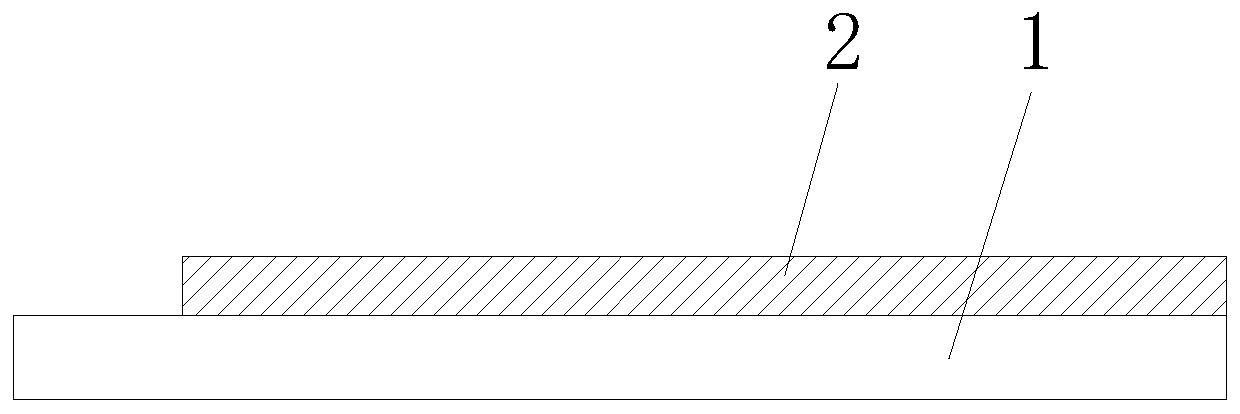

[0023] A metallized film for film capacitors includes a base film 1 and a metal layer 2; the base film 1 includes the following raw materials in terms of mass fractions: 100 parts of PP, 0.2 parts of a transparent modifier, 25 parts of RU composite glue, peroxide exchange 1.2 parts of joint agent, 5 parts of modified hexagonal boron nitride, 42 parts of EOC, 2 parts of flame retardant, and 0.6 parts of anti-aging agent.

Embodiment 2

[0025] A metallized film for film capacitors includes a base film 1 and a metal layer 2; the base film 1 includes the following raw materials in terms of mass fractions: 100 parts of PP, 0.5 parts of a transparent modifier, 18 parts of RU composite glue, peroxide exchange 0.3 parts of joint agent, 32 parts of modified hexagonal boron nitride, 30 parts of EOC, 0.8 parts of flame retardant, and 1.5 parts of anti-aging agent.

Embodiment 3

[0027] A metallized film for film capacitors includes a base film 1 and a metal layer 2; the base film 1 includes the following raw materials in terms of mass fractions: 100 parts of PP, 0.35 parts of a transparency modifier, 21 parts of RU composite glue, peroxide exchange 0.7 parts of joint agent, 18 parts of modified hexagonal boron nitride, 36 parts of EOC, 1.4 parts of flame retardant, and 1 part of anti-aging agent.

[0028] Among the above-mentioned embodiments 1-3, the overall performance and quality of embodiment 3 are better than embodiments 1 and 2.

[0029] A processing method for a metallized film for a film capacitor, comprising the following steps:

[0030] Step1. Preparation of base film 1

[0031] First put PP, transparent modifier, RU composite glue and peroxide crosslinking agent into the kneader according to the above mass fraction for heat treatment, mix well, and then add modified hexagonal boron nitride, EOC, flame retardant And anti-aging agent and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com