Preparation method and application of organic framework supported CeO2/CuO electrocatalytic material

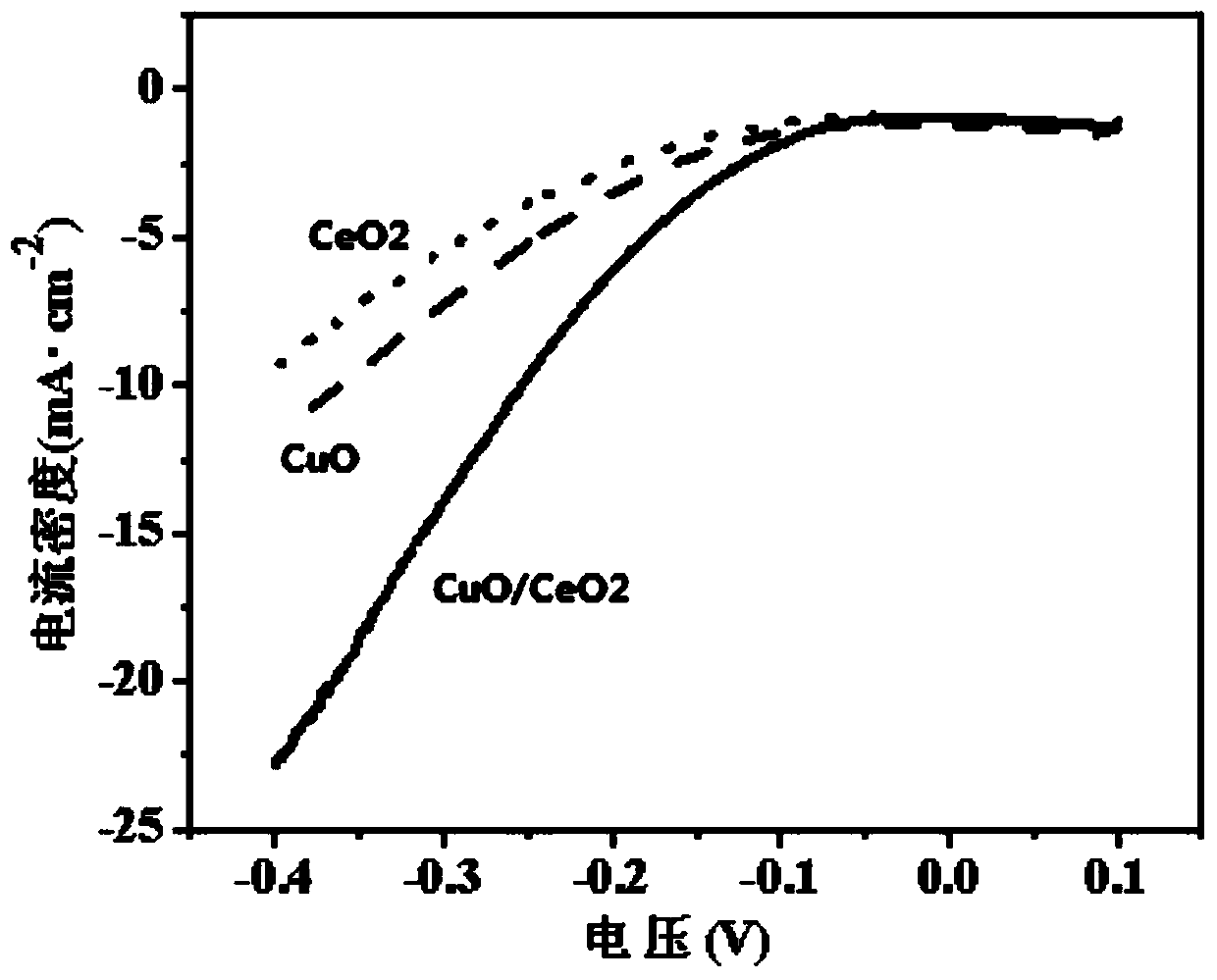

An electrocatalytic material and catalytic material technology, which are applied in the field of organic framework support CeO2/CuO electrocatalytic material preparation to achieve the effect of high repeatability, suitable for large-scale production and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

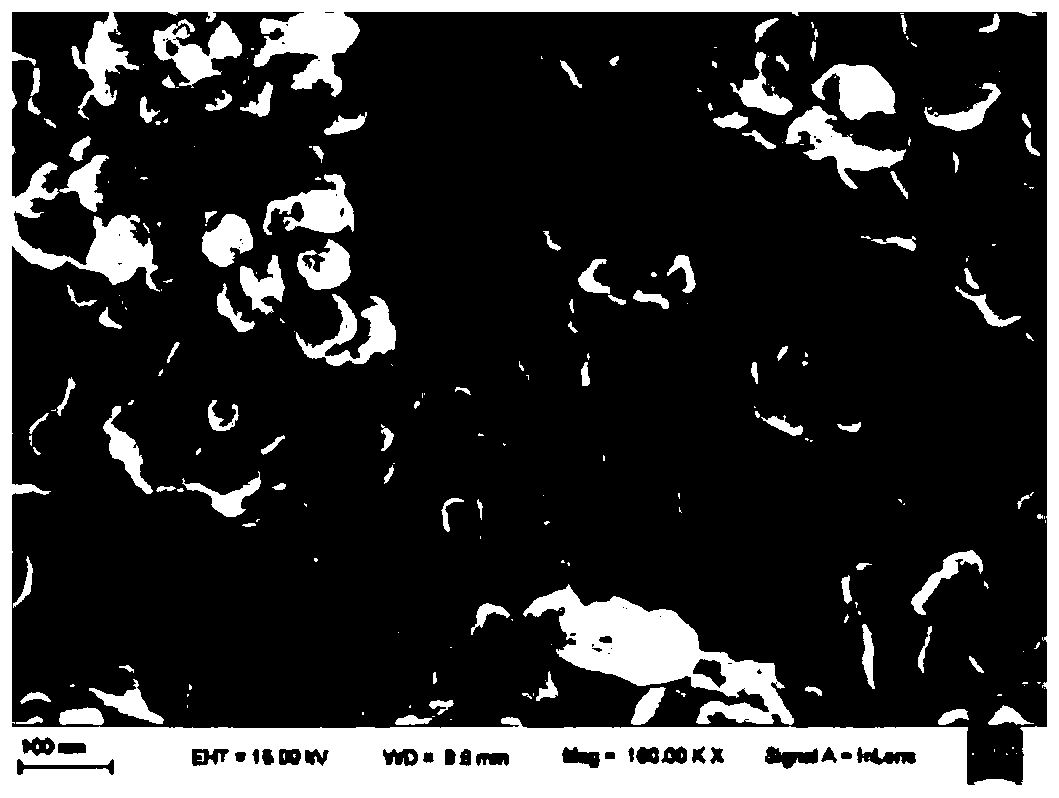

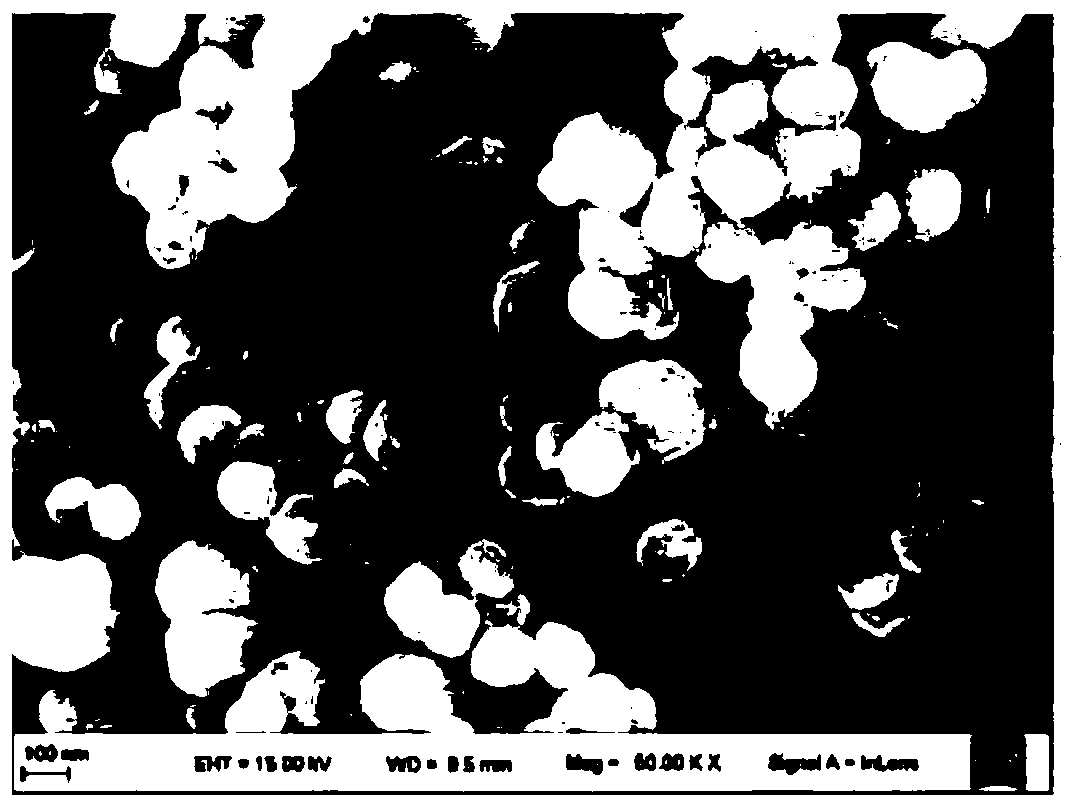

[0031] A metal-organic framework supporting CeO 2 / CuO composite total water splitting electrocatalytic material preparation method, the specific steps are as follows:

[0032] Step 1. Dissolve 1 mmol of copper acetate in 10 mmol of deionized water, stir magnetically at 700 r / min for 20 min, and prepare solution A.

[0033] Step 2. Dissolve 1 mmol of cerium acetate in 10 mmol of deionized water, and magnetically stir at 700 r / min for 20 min to prepare solution B.

[0034] Step 3. Weigh 2mmol of triethylamine and add it to 5mmol ethanol solution. After it is completely dissolved, mix it with solution B evenly, sonicate for 10min, add 5mmol of 3,4-pyridinedicarboxylic acid, and sonicate for 10min to prepare Solution C.

[0035] Step 4. Using ITO (conductive glass) (1cm×1cm) as the working electrode, the Pt electrode as the counter electrode, and the saturated calomel electrode (SCE) as the reference electrode, prepare the original CuO nanosheet array in the A solution by elect...

Embodiment 2

[0039] A metal-organic framework supporting CeO 2 / CuO composite total water splitting electrocatalytic material preparation method, the specific steps are as follows:

[0040] Step 1. Dissolve 1mmol of copper nitrate in 5mmol of deionized water, stir magnetically at 800r / min for 20min, and prepare solution A.

[0041] Step 2, get 1mmol cerium nitrate and dissolve in 5mmol deionized water, 800r / min magnetic stirring 20min, prepare solution B.

[0042] Step 3. Weigh 3mmol of ethylenediamine and add it to 10mmol of methanol solution. After it is completely dissolved, mix it with solution B evenly, sonicate for 10min, add 6mmol of 2,6-pyridinedicarboxylic acid, and sonicate for 10min. Prepare solution C.

[0043] Step 4. Using ITO (conductive glass) (1cm×1cm) as the working electrode, the Pt electrode as the counter electrode, and the saturated calomel electrode (SCE) as the reference electrode, prepare the original CuO nanosheet array in the A solution by electrodeposition . ...

Embodiment 3

[0047] A metal-organic framework supporting CeO 2 / CuO composite total water splitting electrocatalytic material preparation method, the specific steps are as follows:

[0048] Step 1. Dissolve 1mmol of copper chloride in 8mmol of deionized water, and stir magnetically at 500r / min for 20min to prepare solution A.

[0049] Step 2, get 1mmol of cerium chloride and dissolve in 8mmol of deionized water, and stir magnetically at 500r / min for 20min to prepare solution B.

[0050] Step 3. Weigh 2.5mmol dodecylamine and add it to 10mmol propanol solution. After it is completely dissolved, mix it with solution B evenly, sonicate for 10min, add 8mmol of 3,5-pyridinedicarboxylic acid, and sonicate for 10min , to prepare solution C.

[0051] Step 4. Using ITO (conductive glass) (1cm×1cm) as the working electrode, the Pt electrode as the counter electrode, and the saturated calomel electrode (SCE) as the reference electrode, prepare the original CuO nanosheet array in the A solution by e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com