Preparation method of ZnO film and application of ZnO film to ultraviolet sensor

A film and substrate technology, applied in the field of film preparation and sensors, can solve problems such as reducing internal electron mobility, achieve good characteristics of flexible ultraviolet sensors, improve the preparation process, mechanical properties and the effect of maintaining sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

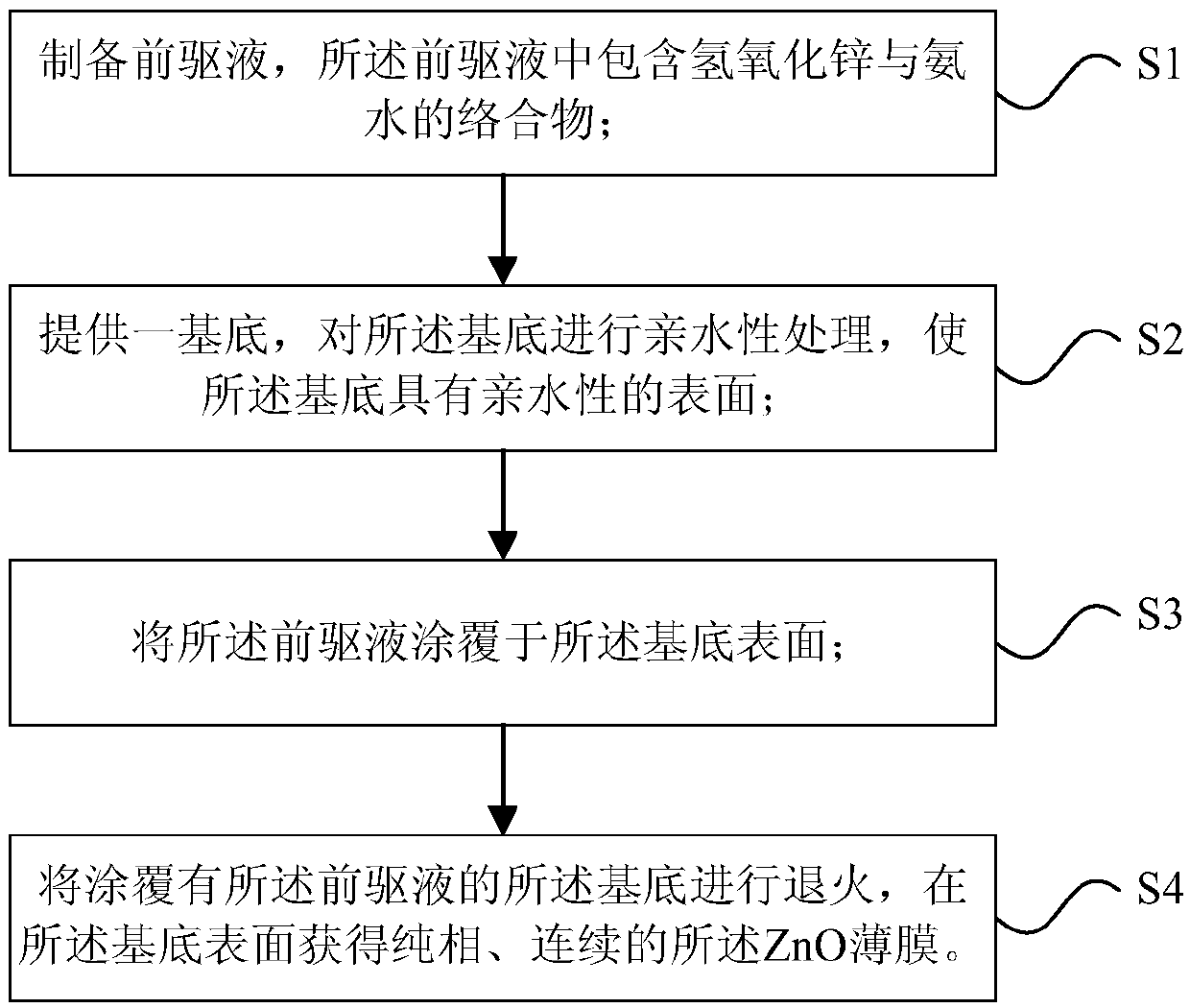

Method used

Image

Examples

Embodiment 1

[0063] Preparation of ZnO thin film:

[0064] (1) Preparation of precursor solution

[0065] Add 75mL, 0.5M zinc nitrate solution into a 200mL conical flask, put magnets in the conical flask and place it on a magnetic stirrer, then add 50mL, 2.5M sodium hydroxide solution dropwise into the ongoing in a stirred zinc nitrate solution. Put the resulting flocculent liquid in a centrifuge tube, centrifuge at a speed of 5000rpm for 2 minutes on a centrifuge, then take out the centrifuge tube, pour out the supernatant in the tube, add deionized water, shake until the sediment in the tube is evenly dispersed, and centrifuge The tubes were again centrifuged at the same parameters. In this way, after repeating 5 times, pour out the supernatant in the last centrifuge tube. The purpose of repeated centrifugation is to reduce the content of sodium ions and nitrate ions in the precipitate. After the above process was completed, the obtained precipitate (zinc hydroxide) was added into 25...

Embodiment 2

[0074] Preparation of UV sensor based on ZnO ultrathin film:

[0075] In this embodiment, an electrode is fabricated on the ZnO thin film prepared in Embodiment 1 to obtain an ultraviolet sensor. Figure 7It is shown as a structural schematic diagram of the ultraviolet sensor, including a substrate 1, a ZnO thin film 2 formed on the surface of the substrate 1, and a pair of electrodes 3 formed on the surface of the ZnO thin film 2, wherein one electrode is used as a positive electrode, and the other electrode is as a negative electrode. In this embodiment, the sensor electrodes are preferably interdigitated positive electrodes and interdigitated negative electrodes.

[0076] As an example, the preparation process is as follows: use carbon paste as the coating, transfer the electrode to the substrate with ZnO film by screen printing technology, and then bake the device printed with the electrode on the 80°C baking table for 1h to make the carbon paste The organic solvent in t...

Embodiment 3

[0081] Fabrication of flexible UV sensors based on ZnO ultrathin films:

[0082] When the Schottky junction formed by the ZnO film and the p-type conductive polymer poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) (PEDOT:PSS) is irradiated by ultraviolet light, the ZnO film barrier The electron-hole pairs generated in the region will move in opposite directions under the action of the built-in electric field, and the moving electrons and holes will generate photocurrent in the external circuit. In this embodiment, on the basis of Embodiment 1 and Embodiment 2, the substrate is changed from a glass sheet to a flexible Kapton film (polyimide film), and the interdigitated electrode is replaced by a carbon interdigitated electrode with a C / PEDOT:PSS fork Finger electrodes (in a pair of interdigitated electrodes, one electrode is made of C, and the other electrode is made of PEDOT:PSS), a flexible self-powered ultraviolet sensor can be obtained.

[0083] The following i...

PUM

| Property | Measurement | Unit |

|---|---|---|

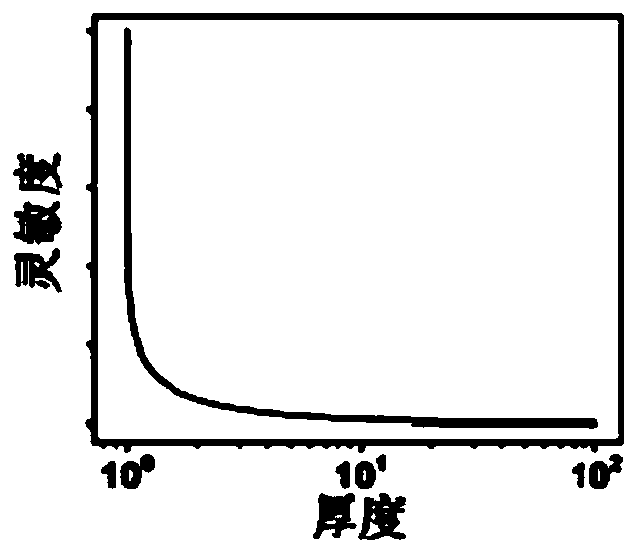

| Thickness | aaaaa | aaaaa |

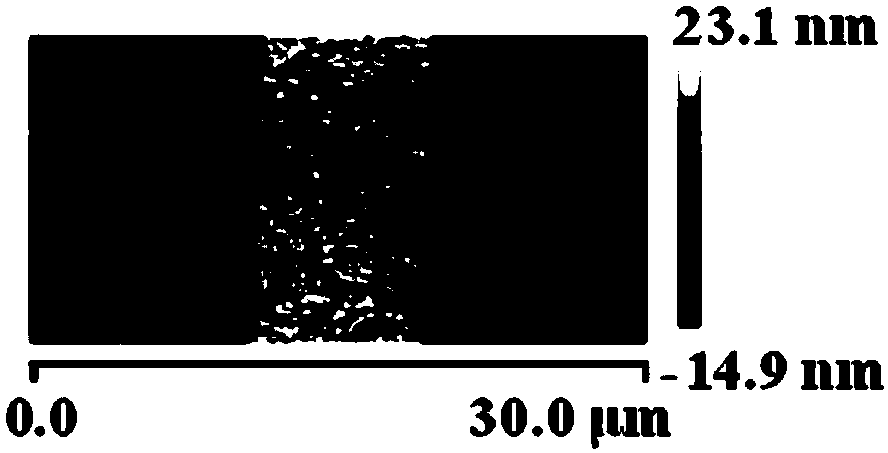

| Roughness | aaaaa | aaaaa |

| Interdigital width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com