Amphipathic random copolymer with disulfide bond and preparation method and application of amphipathic random copolymer

A random copolymer, amphiphilic technology, applied in the field of polymer materials, to achieve the effect of excellent chelating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of functional monomer MALA

[0037] Add lipoic acid (4g, 19mmol) and hydroxyethyl methacrylate (2.5g, 19mmol) into a 100mL single-necked bottle, measure 60mL of dichloromethane, and stir to dissolve in an ice bath. Then add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (7.4g, 36.8mmoL), 4-dimethylaminopyridine (2.4g, 8.2mmoL), and react at room temperature 18h. After the reaction, the above mixed solution was transferred to a 250mL separatory funnel, and extracted according to the following steps: a. 1mol / L hydrochloric acid washing / extracting sample (200mL, divided into 6 times); b. saturated NaHCO 3 Wash / extract sample with solution (150mL, divided into 3 times); c. Wash with saturated NaCl solution / extract sample (150mL, divided into 3 times) until the solution is clear. Then, the solvent was removed by rotary evaporation, and dried in vacuum for about 2 hours to obtain a light yellow transparent liquid.

[0038] (2) Preparation of hy...

Embodiment 2~4

[0045] The process conditions are the same as in Example 1, but in step 3) in the step of preparing the amphiphilic polymer, the ratio of MAPEG containing adjacent hydrophilic segments and hydrophobic monomer MAHA is changed.

[0046] Table 1

[0047]

[0048]

Embodiment 5

[0050] (1) Using the classic liquid phase reduction method, slowly add chloroauric acid solution in the sodium citrate solution to obtain gold nanoparticles with uniform particle size;

[0051] (2) The amphiphilic random copolymer P (MAPEG-co-MALA-co-MAHA) described in Example 1 was dissolved in tetrahydrofuran, and irradiated with ultraviolet light for 0.5-3 hours. At room temperature, an aqueous solution of gold nanoparticles was added and stirred overnight. Open the door, and after THF is completely volatilized, refrigerate and centrifuge to obtain Au@P(MAPEG-co-MALA-co-MAHA) nanoparticles. The ratio of P(MAPEG-co-MALA-co-MAHA) to THF is 1~3g:1L.

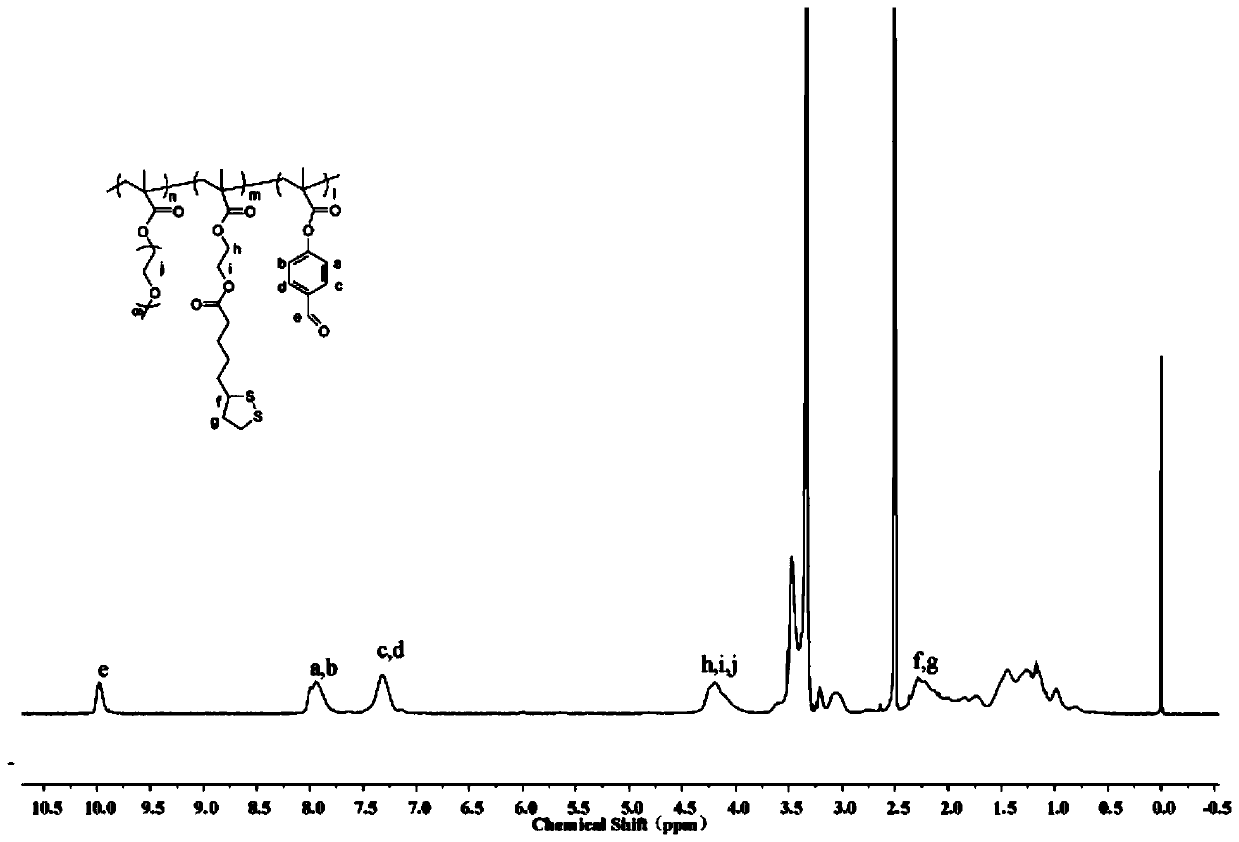

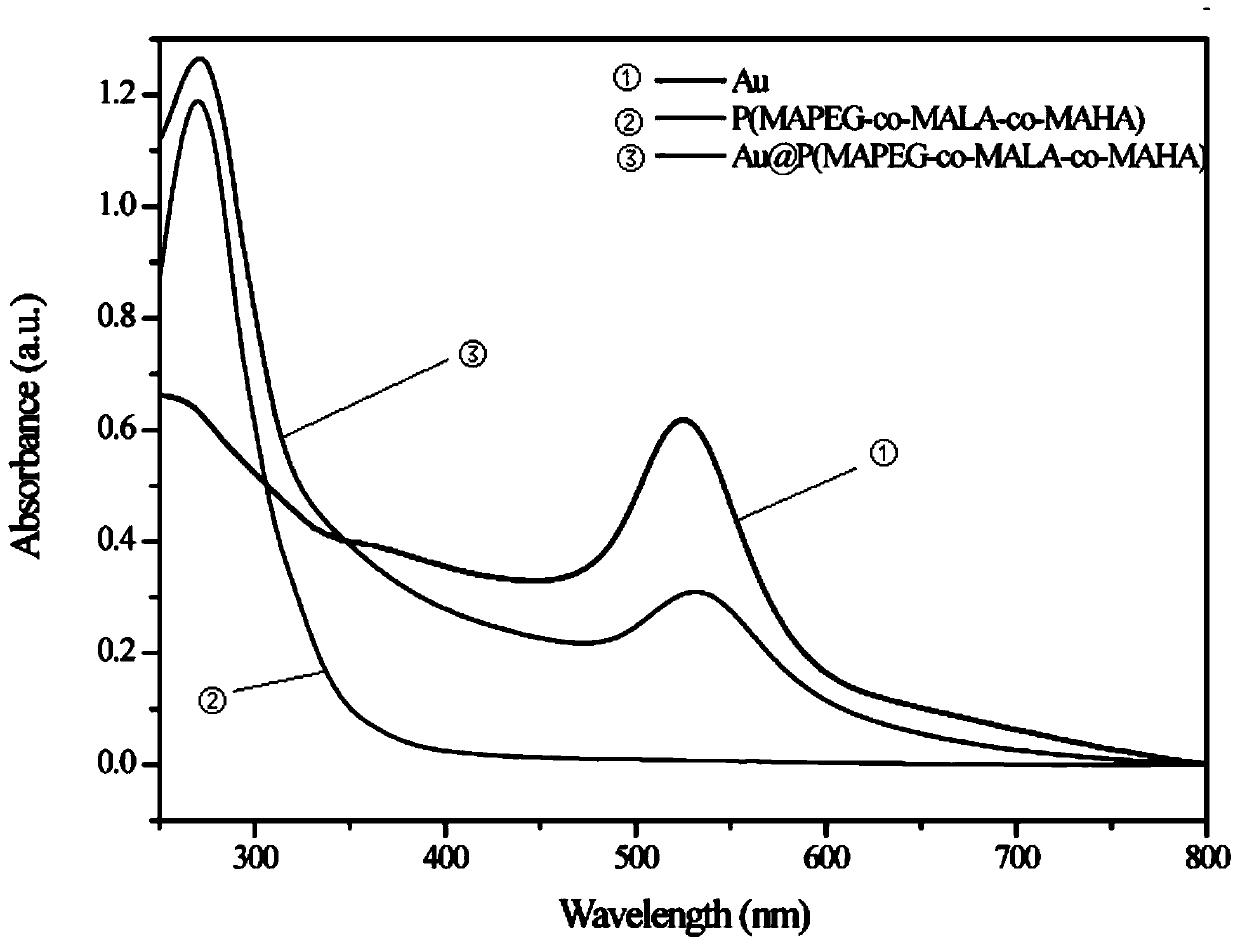

[0052] Such as image 3 , the absorption peak position of the gold nanoparticles prepared in this example is at 525nm, the absorption peak position of the amphiphilic random copolymer is at 250nm, and the polymer@Au nanoparticles have absorption peaks at 250nm and 525nm, proving that, The successful synthesis of the Au@P(MAPEG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com