A kind of functional urea based on modified wax retaining agent and preparation method thereof

A bioactivator and functional technology, which is applied in the field of functional urea and its preparation based on modified wax activator, can solve the problem of inability to achieve the best effect of functional components, simple method of adding functional components, and no direct access to functional substances. Protection and other issues, to achieve the effect of saving field operation time, reducing labor intensity of farmers, and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

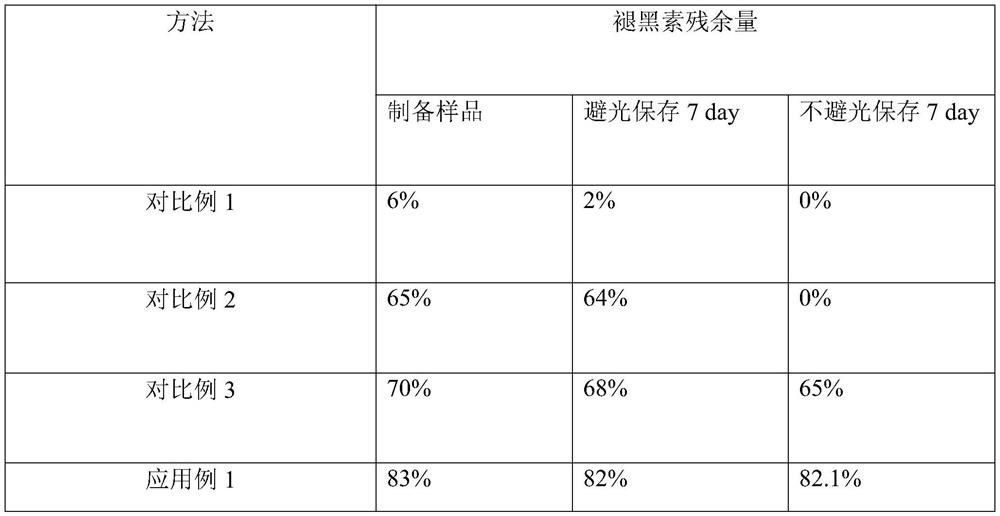

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of auxiliary agent for keeping alive

[0034] Add composite wax 85g under inert gas protection and heating and stirring condition, under heating and stirring, described composite wax is melted, then under stirring, add dropwise in the acrylonitrile that is dissolved with dicumyl peroxide, then add dropwise 5 , 6-dicarboxyindole melanin, heated at 40°C, stirring at a speed of 30 rpm for 1.0h, wherein 4g of dicumyl peroxide, 10g of acrylonitrile, 5,6-dicarboxyindole Indole melanin is 1g. The mixture containing the graft copolymer was obtained, and after hot filtration, methanol was added for precipitation separation, washing, and drying to obtain grafted modified paraffin, and the grafting rate was measured to be 45%.

[0035] In the present invention, the composite wax is a commercially available composite wax product produced by Henan Yuyang Wax Industry Co., Ltd.

Embodiment 2

[0036] Embodiment 2: the preparation of auxiliary agent for keeping alive

[0037] Add 85g of composite wax under inert gas protection and heating and stirring conditions, make the composite wax melt under heating and stirring, then add dropwise in the butadiene that is dissolved in cumene hydroperoxide under stirring, then add dropwise Iron oxide black, heated at 50°C, stirring and reacting for 1.0h under the condition of rotating speed of 35 rpm, to obtain a new type of grafted modified paraffin; wherein cumene hydroperoxide is 4.5g, butadiene is 10g, iron oxide Black is 0.5g. The mixture containing the graft copolymer was obtained, and after hot filtration, methanol was added for precipitation separation, washing and drying to obtain the graft modified paraffin wax, and the grafting rate was measured to be 50%.

Embodiment 3

[0038] Embodiment 3: the preparation of auxiliary agent for keeping alive

[0039]Add 80g of composite wax under inert gas protection and heating and stirring conditions, make described composite wax melt under heating and stirring, then add dropwise in the styrene that is dissolved with benzoyl peroxide under stirring, then add dropwise 5, 6-dicarboxyindole carboxylic acid melanin was heated at 60°C and stirred for 0.5h at a rotational speed of 20 rpm to obtain a new type of grafted modified paraffin; wherein benzoyl peroxide was 3.5g and styrene was 10g, 5,6-dicarboxyindolecarboxylic acid melanin is 1.5g. The mixture containing the graft copolymer was obtained, and after hot filtration, methanol was added for precipitation separation, washing and drying to obtain the graft modified paraffin wax, and the grafting rate was measured to be 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com