Synthetic method of low-toxicity low-harm environment-friendly solvent green 3

An environment-friendly solvent and synthetic method technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems affecting reaction selectivity, poor color reproducibility, operator poisoning, etc., to achieve Improved product purity, good high temperature stability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

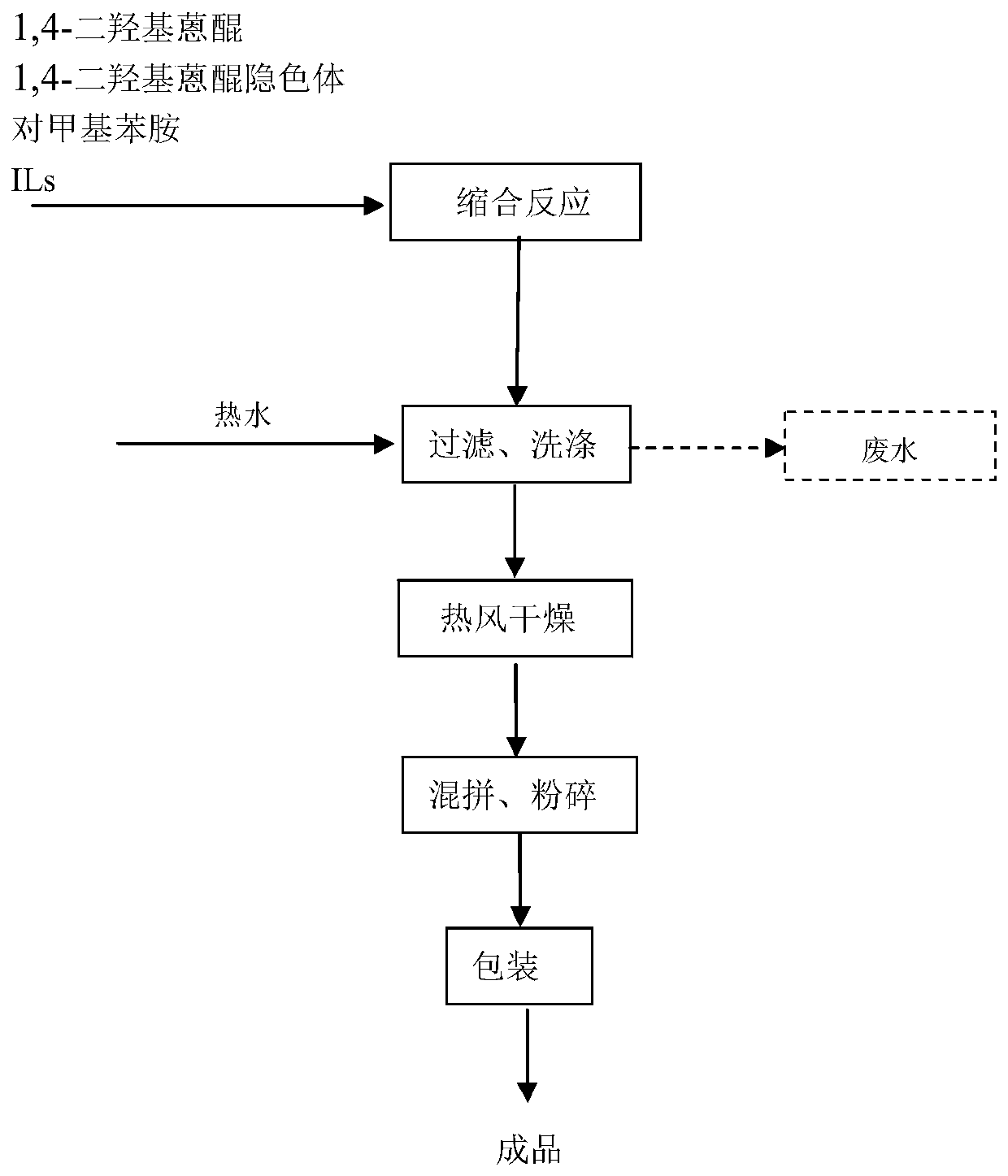

[0023] A kind of synthetic method of low toxicity and low harm environment-friendly solvent green 3 of the present invention comprises the following steps:

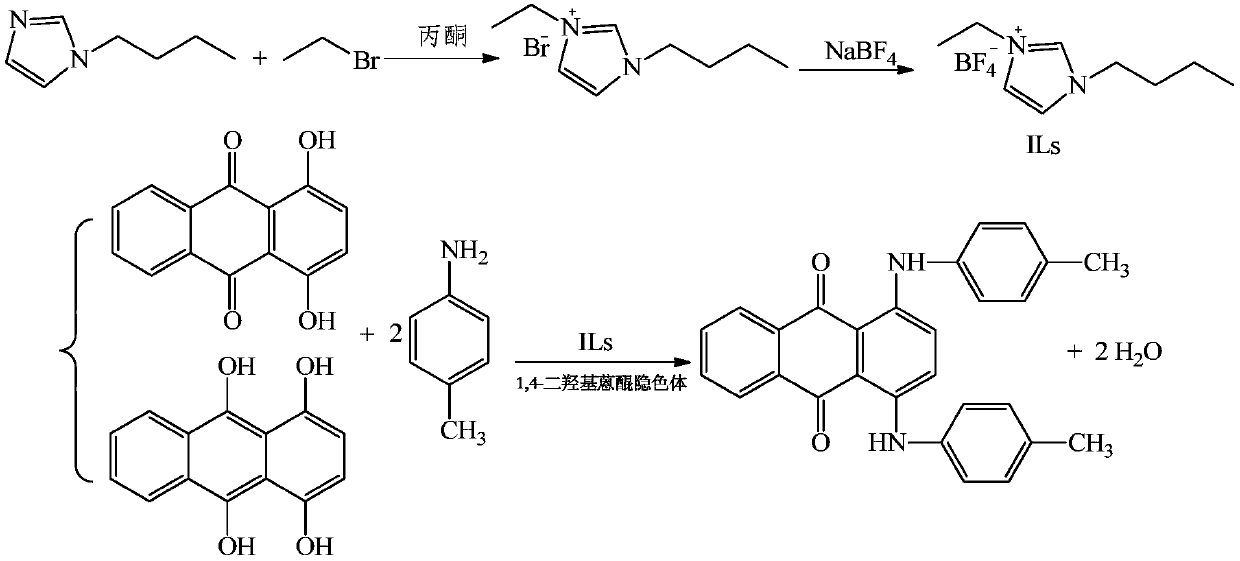

[0024] (a) Add N-butylimidazole and acetone to the reaction vessel, then slowly add bromoethane dropwise under stirring for reaction, add sodium tetrafluoroborate after reacting for 2-4h for anion exchange, and continue stirring for 4-6h, Acetone is removed by distillation under reduced pressure to obtain an ionic liquid; the mass ratio of N-butylimidazole, ethyl bromide, and sodium tetrafluoroborate is 1 to 1.1:1:1, and the mass ratio of acetone to N-butylimidazole is 1.2 ~1.5:1.

[0025] (b) Raise the temperature of the ionic liquid to 80-90°C, then add 1,4-dihydroxyanthraquinone, 1,4-dihydroxyanthraquinone leuco, and p-methylaniline to the ionic liquid, and stir to raise the temperature to 120- Condensation reaction was carried out at 130°C, and the end point of the reaction was determined by HPLC detection to obtain ...

Embodiment 1

[0030] This embodiment provides a synthetic method of low-toxicity, low-hazard and environment-friendly solvent green 3, which comprises the following steps:

[0031] (a) add 480 kilograms of N-butyl imidazoles, 600 kilograms of acetones in the reaction vessel, then slowly drip 450 kilograms of bromoethanes under stirring to react, add 450 kilograms of sodium tetrafluoroborates after reacting 3h and carry out anion exchange, Stirring was continued for 5h, and acetone was removed by distillation under reduced pressure to obtain an ionic liquid;

[0032] (b) Heat up the ionic liquid to 85°C, then add 900 kg of 1,4-dihydroxyanthraquinone, 300 kg of 1,4-dihydroxyanthraquinone leuco, and 1,800 kg of p-methylaniline to the ionic liquid, and stir The temperature is raised to 125°C for condensation reaction, and the end point of the reaction is determined by HPLC detection to obtain the first mixed solution;

[0033] (c) cooling the first mixed solution to 45°C for suction filtration...

Embodiment 2

[0035]The present embodiment provides a kind of synthetic method of low toxicity, low harm and environment-friendly solvent green 3, which is basically the same as that in Example 1, except that the amount of p-methylaniline added in step (b) is 1200 kilograms; finally After drying, crushing and packaging, 1991 kg of solvent green 3 finished product was obtained; the yield was 95.2%, the HPLC content was 98.65%, △E 0.486, △C 0.388 partial bright, pressure value 0.19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com