A ceramic fiber reinforced high-strength nylon plastic and its application in the electrical field

A ceramic fiber and nylon plastic technology, applied in the nylon field, can solve the problems of concentration of gravity, difficulty in uniform dispersion of inorganic fibers, and decreased mechanical properties, and achieve the effects of good insulation and heat resistance, good dispersibility, and superior mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

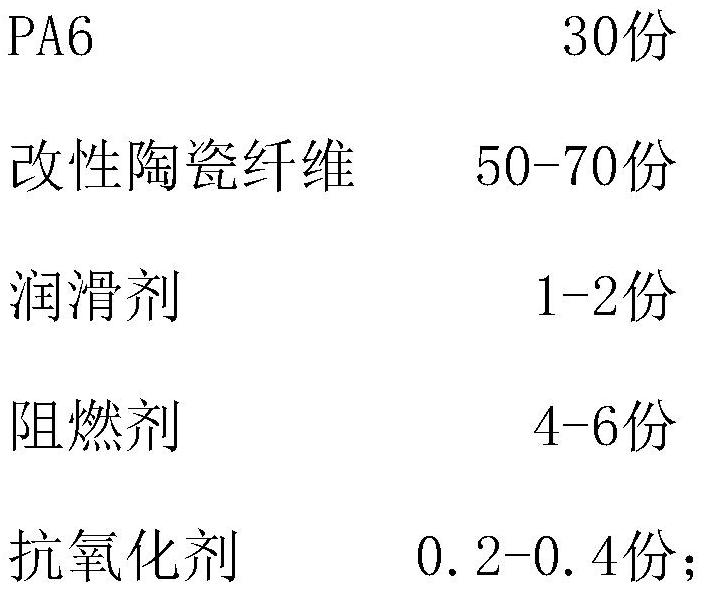

[0026] A high-strength nylon plastic reinforced with ceramic fibers, comprising the following raw materials in parts by weight:

[0027]

[0028]

[0029] The preparation method of described modified ceramic fiber comprises the steps:

[0030] (1) 10 parts by weight of PA66 are dissolved in the formic acid of 100 parts by weight to form a nylon solution;

[0031] (2) Add 50 parts by weight of silicon nitride fibers to the nylon solution, stir evenly to obtain a suspension;

[0032] (3) Spray drying the suspension to obtain the modified ceramic fiber.

[0033] Wherein, the melt index of the PA6 under the condition of 230° C. / 2.16 kg is 17 g / 10 min.

[0034] Wherein, the melt index of the PA66 under the condition of 275° C. / 5 kg is 40 g / 10 min.

[0035] Wherein, the silicon nitride fiber has a diameter of 100 nm and a length of 2 μm.

[0036] Wherein, the lubricant is talcum powder.

[0037] Wherein, the flame retardant is ammonium polyphosphate.

[0038] Wherein, th...

Embodiment 2

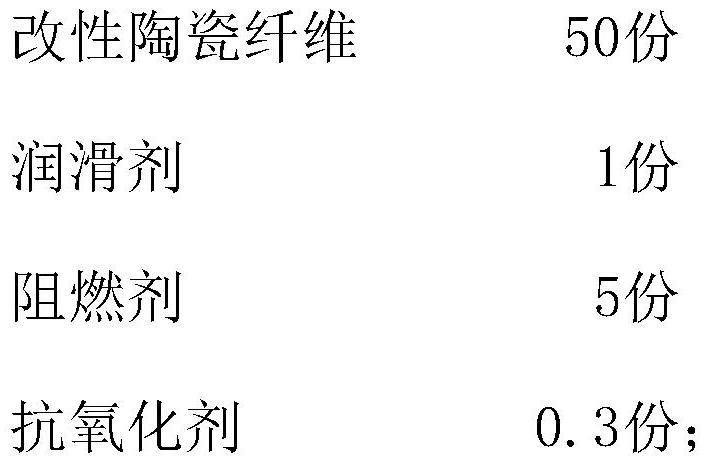

[0042] A high-strength nylon plastic reinforced with ceramic fibers, comprising the following raw materials in parts by weight:

[0043]

[0044]

[0045] The preparation method of described modified ceramic fiber comprises the steps:

[0046] (1) 10 parts by weight of PA66 are dissolved in the formic acid of 100 parts by weight to form a nylon solution;

[0047] (2) Add 55 parts by weight of silicon nitride fibers to the nylon solution, stir evenly to obtain a suspension;

[0048] (3) Spray drying the suspension to obtain the modified ceramic fiber.

[0049] Wherein, the melt index of the PA6 under the condition of 230° C. / 2.16 kg is 20 g / 10 min.

[0050] Wherein, the melt index of the PA66 under the condition of 275° C. / 5 kg is 60 g / 10 min.

[0051] Wherein, the silicon nitride fiber has a diameter of 200 nm and a length of 3 μm.

[0052] Wherein, the lubricant is polyethylene wax.

[0053] Wherein, the flame retardant is aluminum hydroxide.

[0054] Wherein, the...

Embodiment 3

[0058] A high-strength nylon plastic reinforced with ceramic fibers, comprising the following raw materials in parts by weight:

[0059]

[0060]

[0061] The preparation method of described modified ceramic fiber comprises the steps:

[0062] (1) 10 parts by weight of PA66 are dissolved in the formic acid of 100 parts by weight to form a nylon solution;

[0063] (2) Add 50 parts by weight of silicon nitride fibers to the nylon solution, stir evenly to obtain a suspension;

[0064] (3) Spray drying the suspension to obtain the modified ceramic fiber.

[0065] Wherein, the melt index of the PA6 under the condition of 230° C. / 2.16 kg is 18.5 g / 10 min.

[0066] Wherein, the melt index of the PA66 under the condition of 275° C. / 5 kg is 50 g / 10 min.

[0067] Wherein, the silicon nitride fiber has a diameter of 150 nm and a length of 2.5 μm.

[0068] Wherein, the lubricant is a mixture of talcum powder and calcium stearate in a weight ratio of 1:2.

[0069] Wherein, the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com