Method for producing biomass granular fuel from litchi residues

A technology of biomass particles and waste, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of inability to meet the large demand of diners, insufficient supply of litchi wood fuel, etc., to improve the production turnover efficiency, and it is not easy to separate and drop powder. , the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

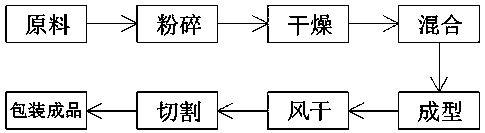

[0037] A method for producing biomass pellet fuel from lychee waste, the production method comprising the following steps:

[0038] (1) Crushing the collected lychee shells and cores, drying them to a moisture content of 15%, and then sieving to obtain raw material A;

[0039] (2) The collected lychee leaves are crushed, dried to a moisture content of 15%, and then sieved to obtain raw material B;

[0040] (3), take the charcoal powder after charcoal pulverization and sieve, take the sugarcane pith after bagasse depitting;

[0041](4) Put raw material A, raw material B, charcoal powder and sugarcane pith into the mixing equipment according to the ratio and mix evenly;

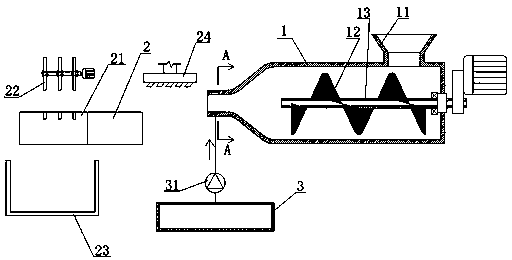

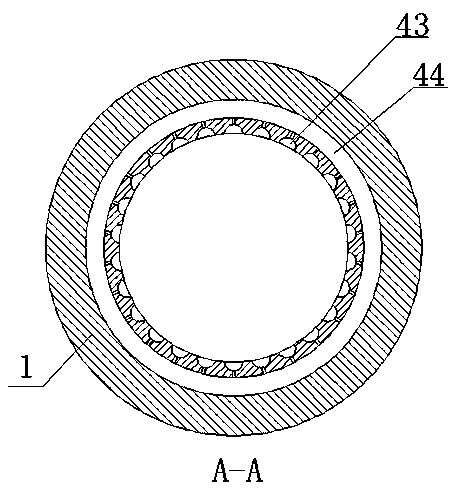

[0042] (5) Add the mixture obtained in step (4) to the molding equipment for molding, and apply a layer of curing liquid on the surface of the fuel after molding, and air-dry the curing liquid;

[0043] (6) Cut the obtained fuel into small sections and pack them into bags to obtain the finished product.

[0...

Embodiment 2

[0051] The difference from Example 1 is that the lychee shell and core are dried to a water content of 18%, and the lychee leaves are dried to a water content of 18%, and the ratio of raw materials in steps (4) by weight is: 30 parts of lychee shell and core ; 40 parts of litchi leaves; 25 parts of charcoal powder; 5 parts of sugarcane pith, do not use curing liquid to smear the surface. A porous membrane is set at the exit of the forming equipment, and there are 12 forming holes on the mold, which can form 12 biomass particles at the same time.

Embodiment 3

[0053] The difference from Example 1 is that the lychee shell and core are dried to a water content of 16%, and the lychee leaves are dried to a water content of 16%, and the ratio of raw materials in steps (4) by weight is: 30 parts of lychee shell and core ; 40 parts of litchi leaves; 26 parts of charcoal powder; 6 parts of sugarcane pith, using turpentine as a solidification solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com