Preparation method of perovskite passivation layer

A technology of passivation layer and perovskite, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as unsatisfactory effects, and achieve improved quality, low defect state density, and good electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

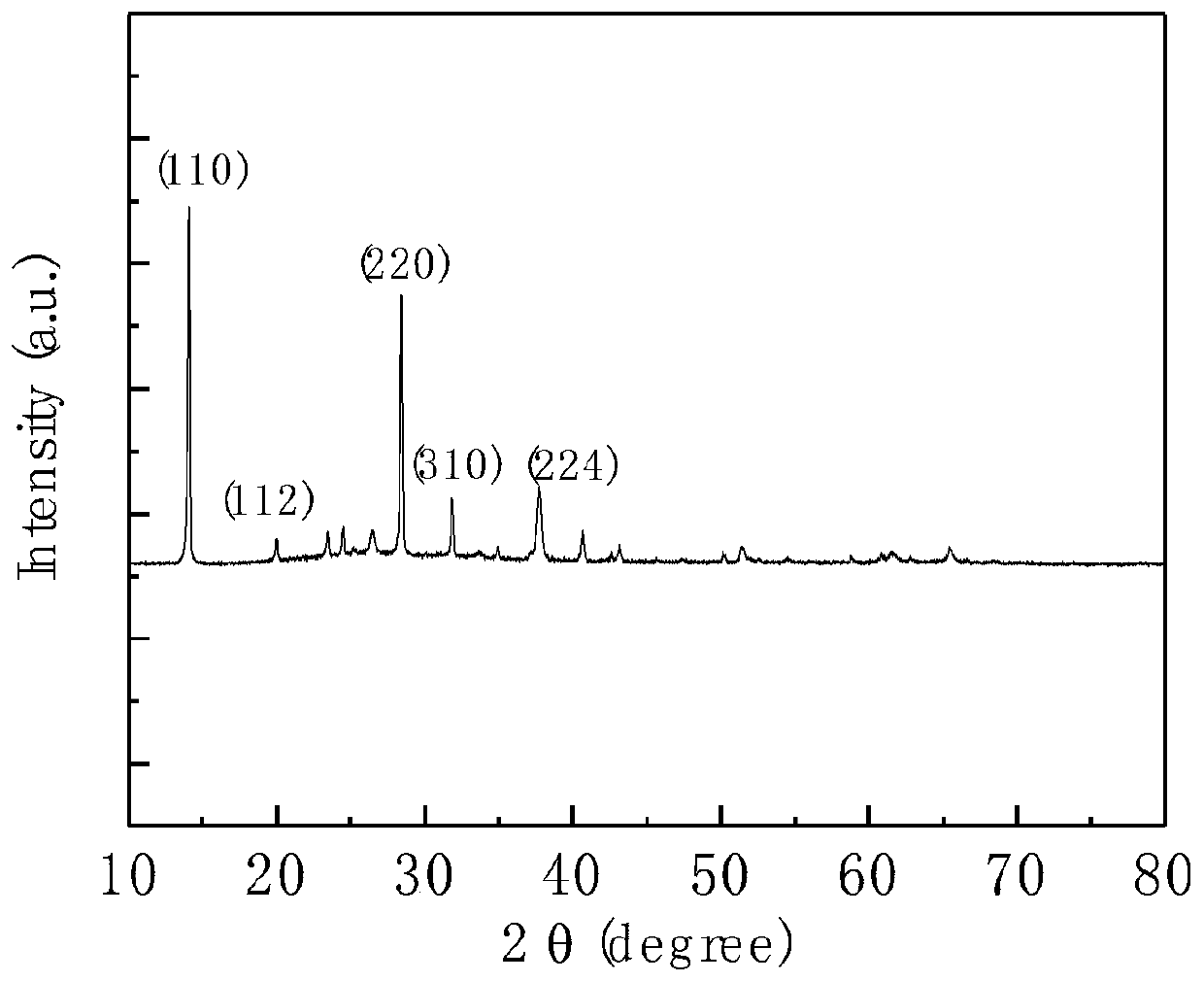

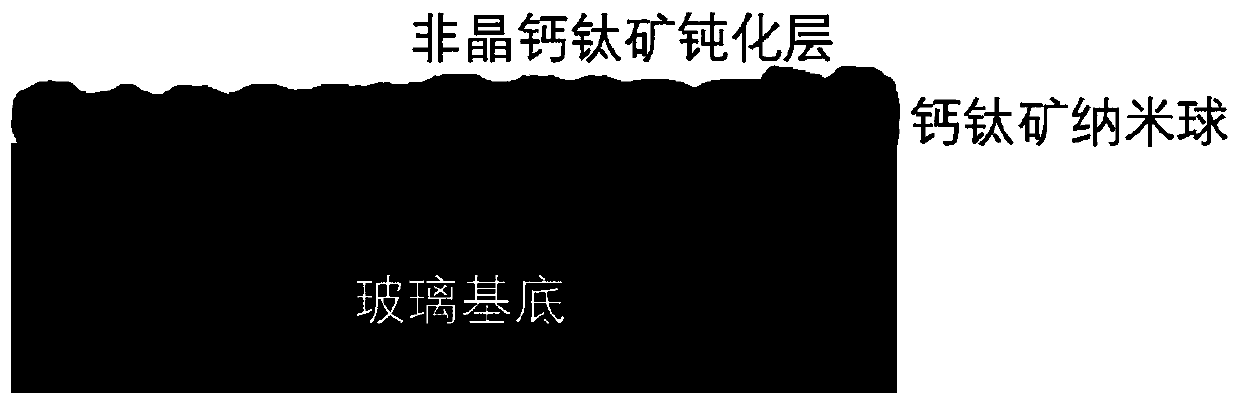

[0025] The schematic diagram of the passivation structure of a method for passivating perovskite materials in this embodiment is as follows figure 1 As shown, it includes from top to bottom: an amorphous perovskite passivation layer, a perovskite nanosphere crystal, and a glass substrate.

[0026] 1. Add 4g PbI 2 , 1 mL cyclohexane, 1 g CH 3 NH 3 1, 2mL isopropyl alcohol (IPA) forms mixed solution and dissolves at 30 ℃, is configured as the precursor solution of passivation layer;

[0027] 2. Take the glass substrate loaded with perovskite nanospheres and place it in a freeze dryer at -10°C for 10 minutes;

[0028] 3. Take out the substrate, and spin-coat 400 μL of the passivation layer precursor solution on the substrate at -5°C to form a 15nm film;

[0029] 4. Move the substrate to a 25°C environment and let it stand for 30 minutes;

[0030] 5. Place the substrate in a freeze dryer at 5°C for 15 minutes;

[0031] 6. Take out the substrate and spin-coat 400 μL of the pa...

Embodiment 2

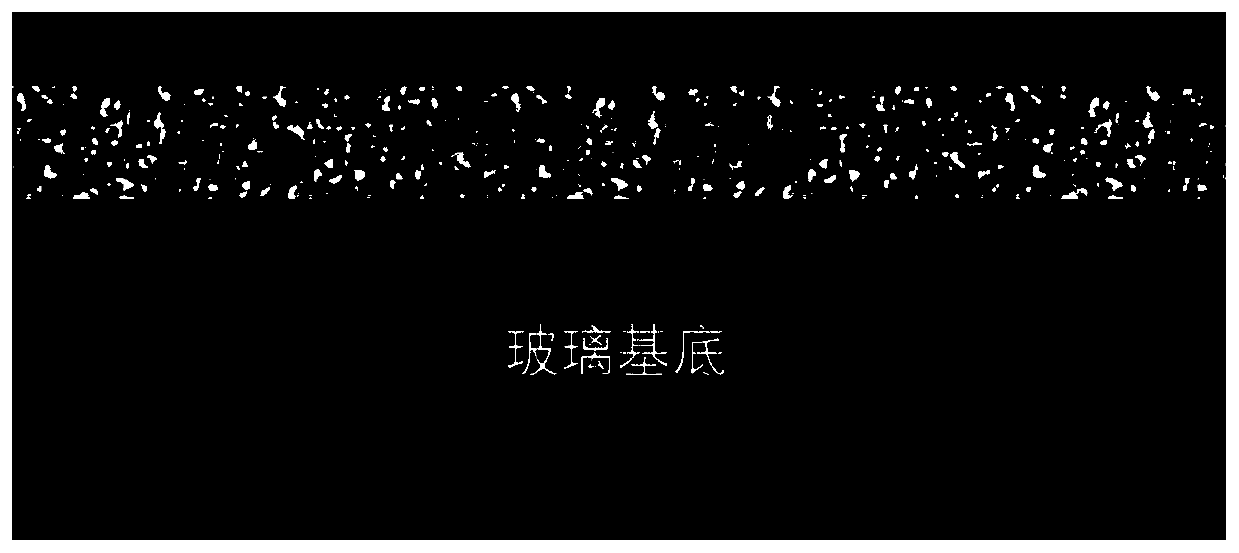

[0036] The schematic diagram of the passivation structure of a method for passivating perovskite materials in this embodiment is as follows figure 2 As shown, it includes from top to bottom: an amorphous perovskite passivation layer, a perovskite polycrystalline film, and a glass substrate.

[0037] 1. Add 3g PbI 2 , 2mL cyclohexane, 1g CH 3 NH 3 1, 2mL IPA is formed in the mixed solution, dissolves at 30 ℃, is configured as the precursor solution of passivation layer;

[0038] 2. Take the glass substrate loaded with the perovskite polycrystalline film and place it in a freeze dryer at -15°C for 6 minutes;

[0039] 3. Take out the substrate, and spin-coat 200 μL of the passivation layer precursor solution on the substrate at -5°C to form a 10nm film;

[0040] 4. Move the substrate to a 30°C environment and let it stand for 30 minutes;

[0041] 5. Place the substrate in a freeze dryer at 5°C for 15 minutes;

[0042] 6. Take out the substrate and spin-coat 400 μL of the p...

Embodiment 3

[0047] The schematic diagram of the passivation structure of a method for passivating perovskite materials in this embodiment is as follows figure 2 As shown, it includes from top to bottom: an amorphous perovskite passivation layer, a perovskite polycrystalline film, and a glass substrate.

[0048] 1. Add 4g PbI 2 , 1 mL cyclohexane, 1 g CH 3 NH 3 1, 2mL IPA is formed in the mixed solution, dissolves at 30 ℃, is configured as the precursor solution of passivation layer;

[0049] 2. Take the glass substrate loaded with perovskite nanospheres and place it in a freeze dryer at -15°C for 20 minutes;

[0050] 3. Take out the substrate, and spin-coat 100 μL of the passivation layer precursor solution on the substrate at -5°C to form an 8nm film;

[0051] 4. Move the substrate to a 30°C environment and let it stand for 30 minutes;

[0052] 5. Place the substrate in a freeze dryer at 5°C for 15 minutes;

[0053] 6. Take out the substrate and spin-coat 400 μL of the passivation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com