Ethylene carbonate production equipment system and production method thereof

A technology for ethylene carbonate and production equipment, applied in the field of chemical product synthesis technology, can solve problems such as ethylene oxide removal, and achieve the effects of reducing exhaust gas emissions, reducing side reactions, and improving the uniformity of bubble distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

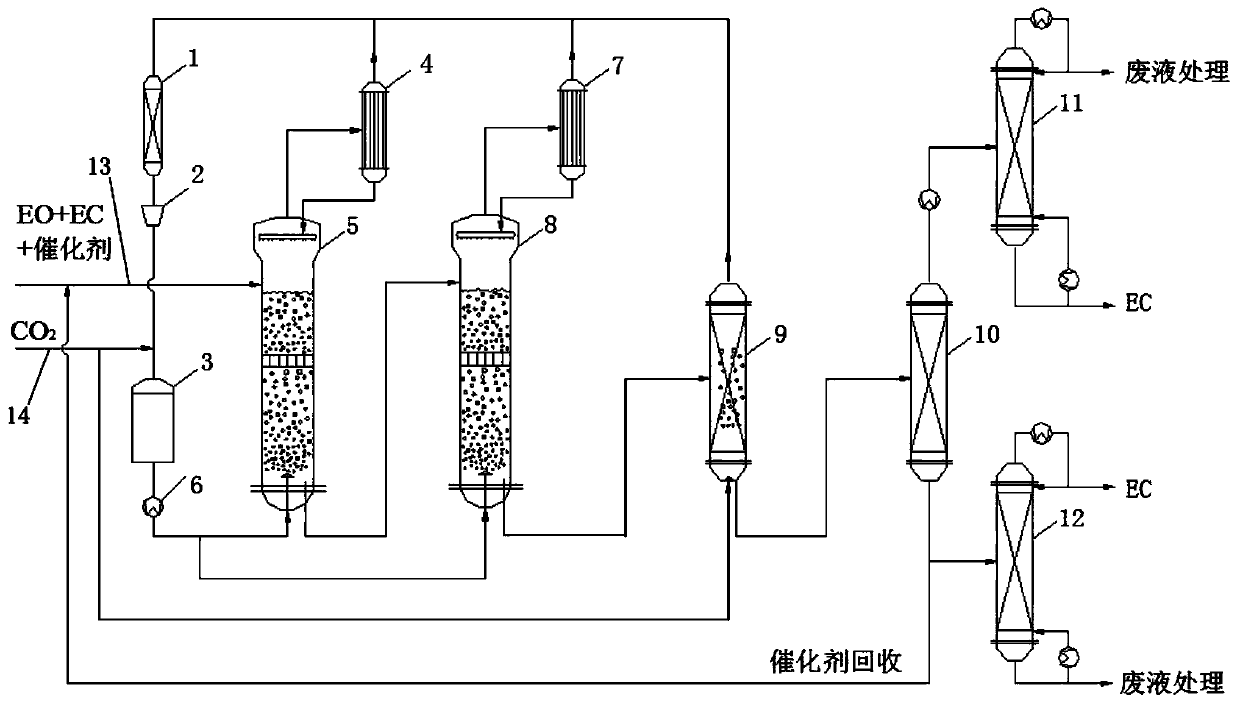

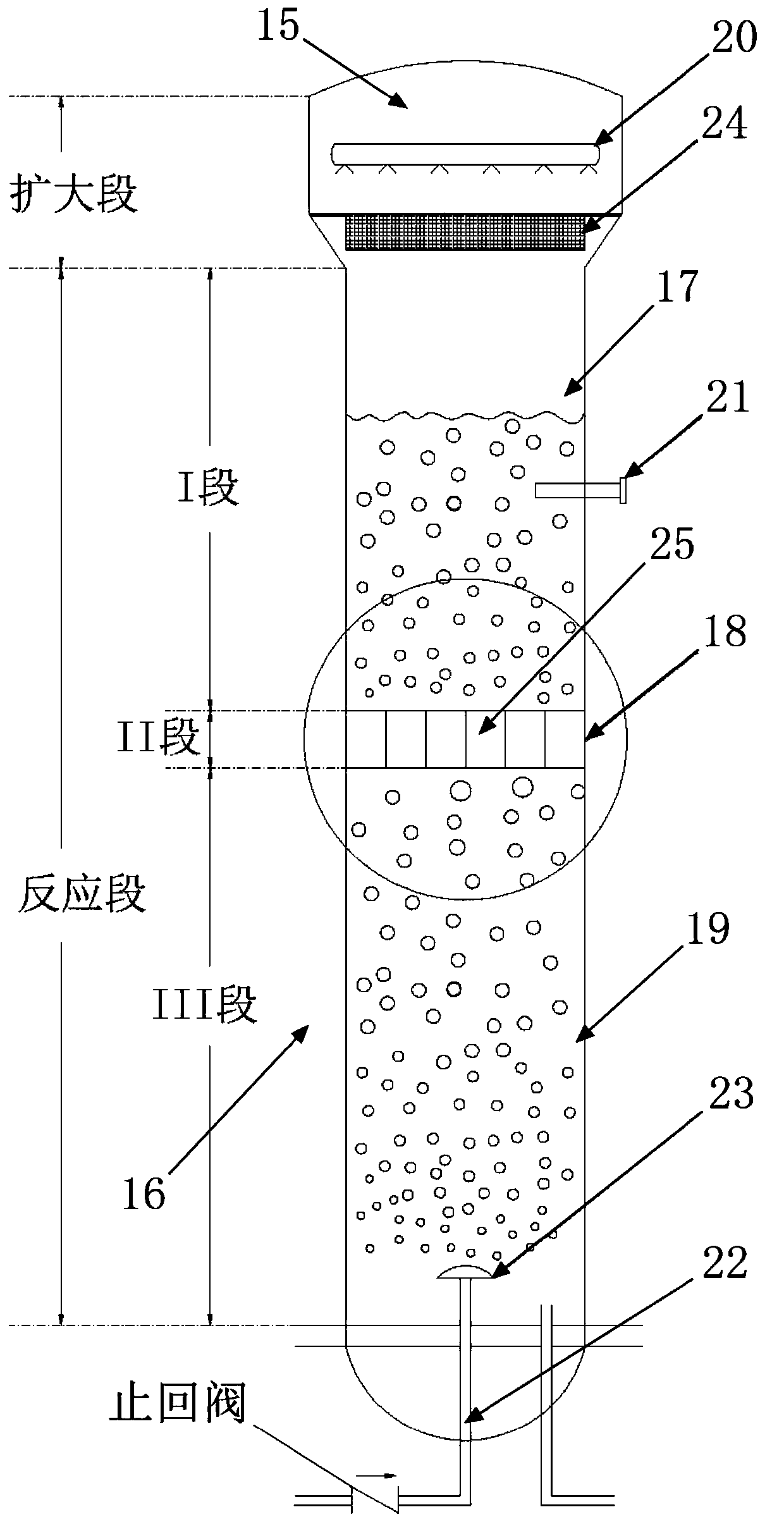

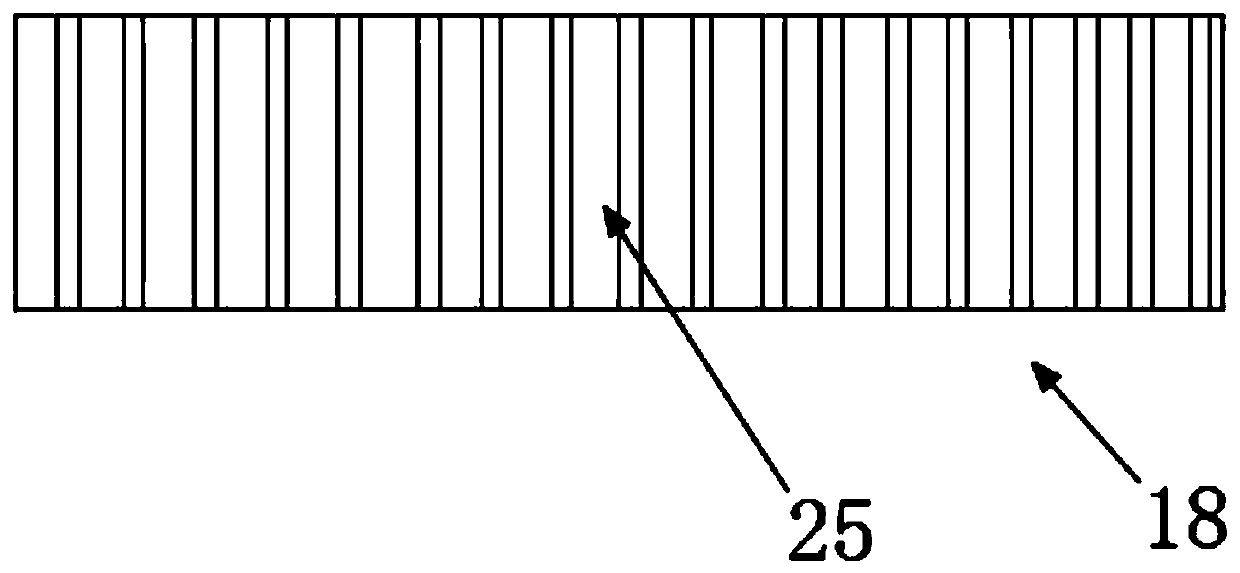

[0045] Such as Figure 1-4 Shown, the production equipment system of a kind of ethylene carbonate provided by the present invention comprises gas drier 1, compressor 2, surge tank 3, the first condenser 4, the first bubble column 5, preheater 6, the first Two condensers 7, the second bubble column 8, stripper 9, ethylene carbonate refining unit, ethylene carbonate recovery tower 12, mixed liquid delivery pipe 13 and carbon dioxide delivery pipe 14, described mixed solution delivery pipe 13 and all The first bubble column 5 is connected to transport ethylene oxide, ethylene carbonate solution, catalyst and auxiliary agent for the first bubble column 5, and the first condenser 4 is connected with the first bubble column The top of 5 is connected by pipeline, the first condenser 4, the gas dryer 1, the compressor 2, the buffer tank 3, the preheater 6, and the first bubble column 5 The bottom of the bottom of the pipeline is connected sequentially, and the bottom of the carbon di...

Embodiment 2

[0050] This embodiment discloses a kind of production method of ethylene carbonate of the present invention, adopts the production equipment system described in embodiment 1 to carry out,

[0051] Specifically include the following steps:

[0052] Step 1. Feeding: Ethylene oxide, ethylene carbonate solution, catalyst and auxiliary agent enter the first bubble column 5 from the mixed liquid feed port 21 through the mixed liquid delivery pipe 13, and carbon dioxide is filled into the buffer through the carbon dioxide delivery pipe 14 After the tank 3, after being heated by the preheater 6, the gas distribution head 23 at the upper end of the intake pipe 22 enters the first bubble tower 5, and the esterification reaction with ethylene oxide generates ethyl carbonate crude product liquid; The ethylene carbonate crude product liquid enters the first bubble column 6 after being discharged from the bottom of the first bubble column 5, and carries out esterification reaction again wit...

Embodiment 3

[0065] This embodiment provides the production equipment system of Embodiment 1 to produce ethylene carbonate. The structural data of the first bubble column and the second bubble column used in this example are shown in Table 1.1.

[0066] Table 1.1 Bubble column structure

[0067]

[0068] The operating pressure (absolute pressure) of the first bubble column and the second bubble column is both 2.5MPa, and the reaction temperature is 120°C. Ethylene oxide is with the feed rate of 315.7kg / h, reclaims ethylene carbonate (containing catalyst tetraethylammonium bromide) with the feed rate of 121.2kg / h and replenishes ethylene carbonate (containing fresh catalyst 1.13kg / h and auxiliary agent zinc bromide 4.7kg / h) with the feeding speed of 11.1kg / h, pass through mixer and mix through respective circuit, feed from the mixed liquid feed inlet of the first bubble column, the first bubble column The reaction liquid is fed from the mixed liquid feed port of the second bubble colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com