High-ductility rice protein edible composite film prepared by ultrasonic synergistic enzyme method

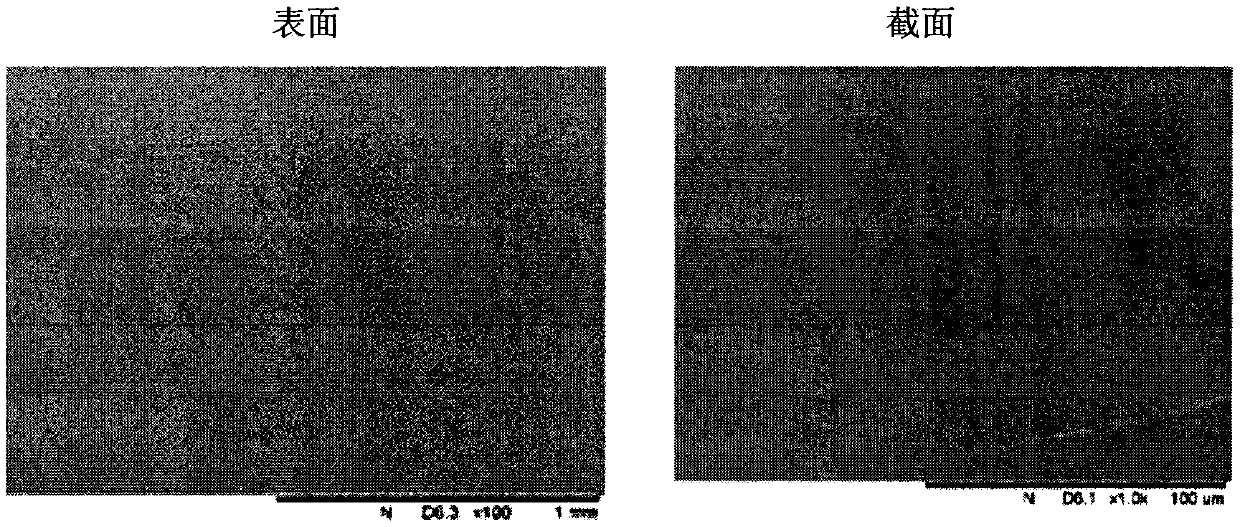

A technology of rice protein and extensibility, applied in the field of rice protein film, can solve the problems of low environmental friendliness, insufficient auxiliary means, unsuitable for large-scale, etc., and achieve the effect of smooth surface, simplified production process, and compact microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a highly extensible rice protein edible composite film, the steps are as follows:

[0031] (1) Preparation of rice protein hydrolyzate: enzymolyze the rice protein with alkaline protease, the degree of hydrolysis is 0%, 4%, 8% and 10%, inactivate at 80°C, centrifuge, take the supernatant, vacuum freeze-dry it into powder;

[0032] (2) Prepare film-forming solution: prepare 200ml of film-forming solution with 4% concentration in a mass ratio of 1:1 with chitosan solution (dissolved in 1% acetic acid), add 1% glycerin, and stir for 4h at 3500rpm , to adjust the pH to 5;

[0033] (3) Film formation: after the solution to be ultrasonically treated is cooled to room temperature, it is poured into a mold at 20° C. and the humidity is 50% RH for 36 hours to prepare a highly extensible rice protein edible composite film.

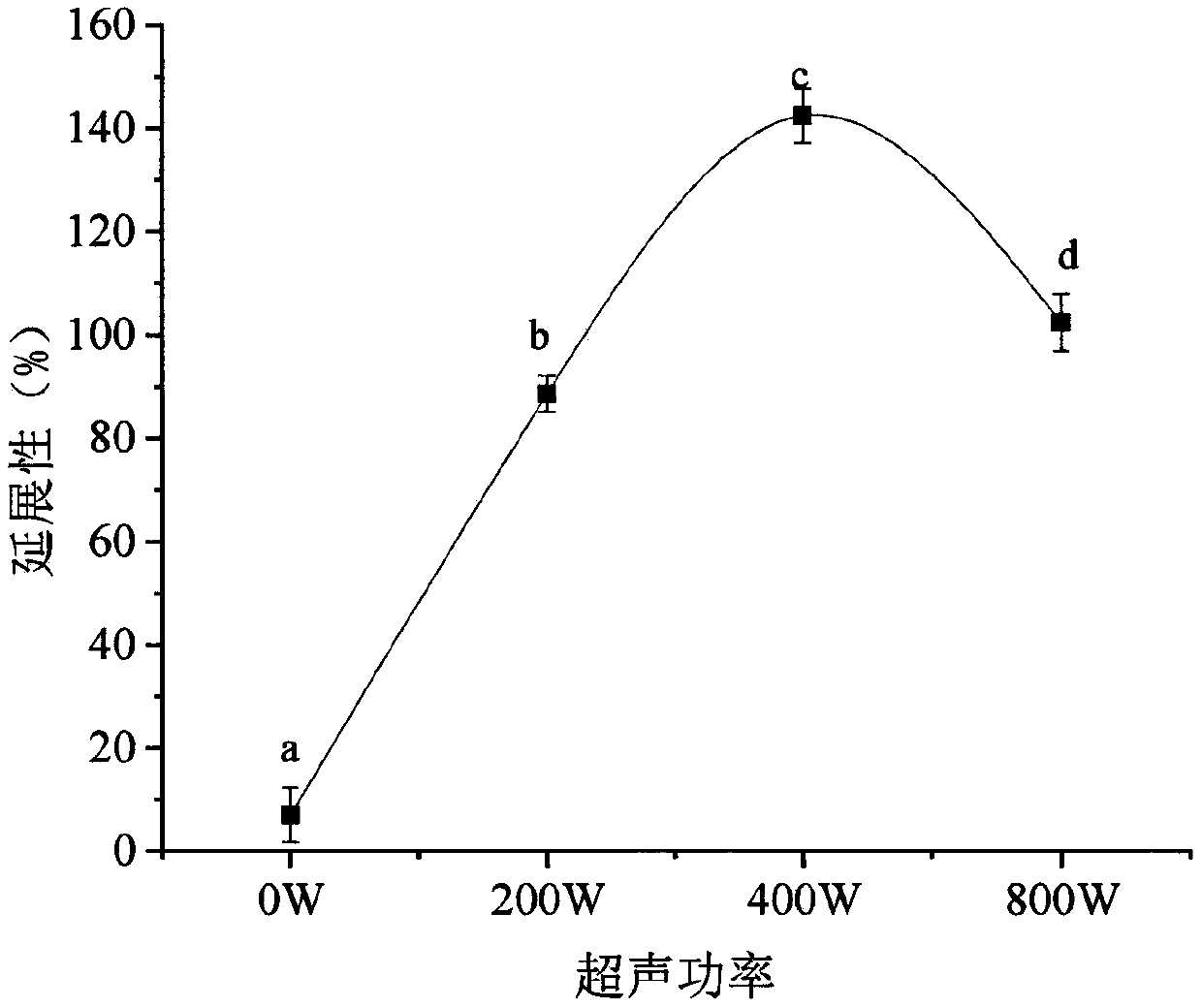

[0034] When the degree of hydrolysis is 0%, the extensibility of the rice protein edible composite film is 7%-10%.

Embodiment 2

[0036] A preparation method of a highly extensible rice protein edible composite film, the steps are as follows:

[0037] (1) Preparation of rice protein hydrolyzate: the rice protein is enzymolyzed by alkaline protease to a degree of hydrolysis of 4%, inactivated at 90° C., centrifuged and the supernatant vacuum freeze-dried into powder;

[0038] (2) Prepare film-forming solution: prepare 200ml of film-forming solution with 3% concentration in a mass ratio of 1:2 with chitosan solution (dissolved in 1% acetic acid), add 0.5% glycerin, and stir for 2h at 4000rpm , to adjust the pH to 4;

[0039] (3) Ultrasonic treatment: use 400W ultrasonic treatment for 30 minutes;

[0040] (4) Film formation: After the solution to be ultrasonically treated is cooled to room temperature, it is poured into a mold at 30° C. and the humidity is 50% RH to prepare a highly extensible rice protein edible composite film.

Embodiment 3

[0042] A preparation method of a highly extensible rice protein edible composite film, the steps are as follows:

[0043] (1) Preparation of rice protein hydrolyzate: the rice protein is enzymolyzed by alkaline protease to a degree of hydrolysis of 10%, inactivated at 90°C, centrifuged and the supernatant is vacuum freeze-dried into powder;

[0044] (2) Prepare film-forming solution: prepare 200ml of film-forming solution with 5% concentration according to the mass ratio of 4:1 with chitosan solution (dissolved in 1% acetic acid), add 1% glycerin, and stir for 1h at 3500rpm , to adjust the pH to 6;

[0045] (3) Ultrasonic treatment: use 400W ultrasonic treatment for 15min, 30min, 45min;

[0046] (4) Film formation: After the solution to be ultrasonically treated is cooled to room temperature, it is poured into a mold, and the highly extensible rice protein edible composite film is prepared at 30° C. and a humidity of 50% RH for 36 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ductility | aaaaa | aaaaa |

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com