A heavy metal adsorbent based on alkali slag recycling and its preparation method and application

A heavy metal and adsorbent technology, applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, chemical instruments and methods, etc., can solve the problems of non-recyclable, complex composition of alkali slag, poor adsorption effect, etc. Treatment cost, obvious adsorption and fixation effect, simple material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

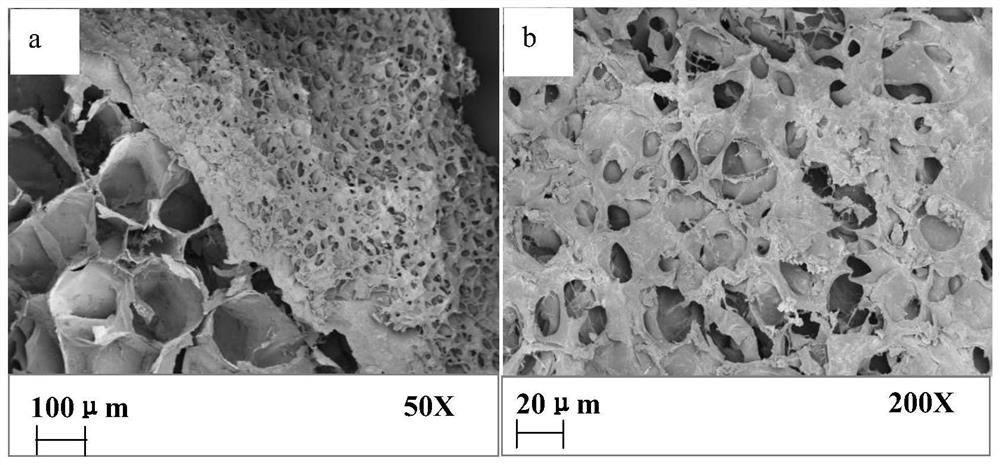

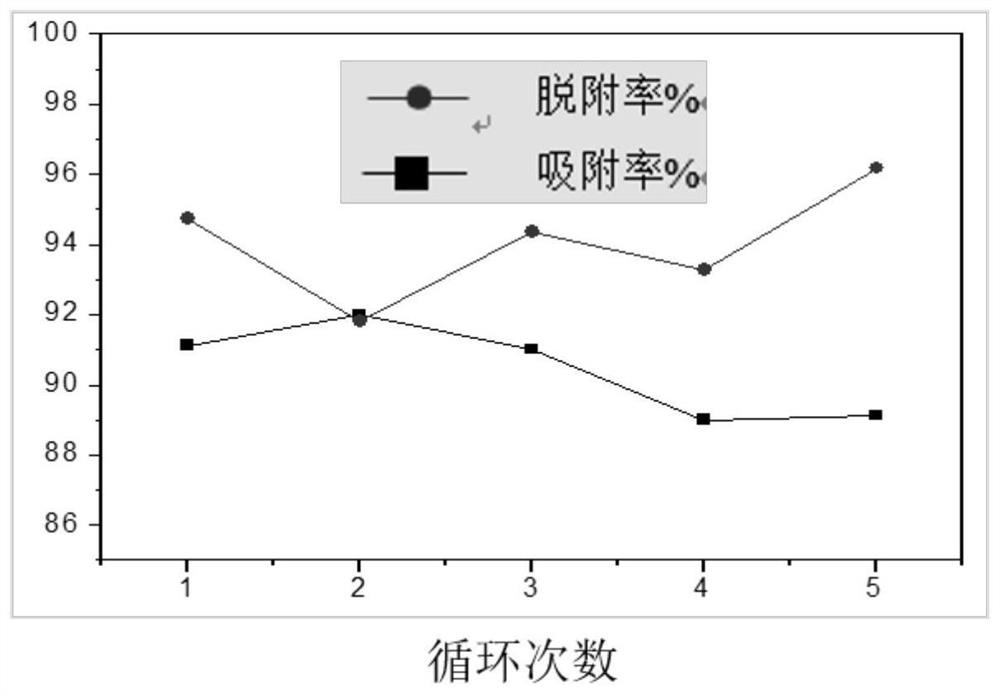

Image

Examples

Embodiment 1

[0042] A heavy metal adsorbent based on alkali slag recycling and a preparation method thereof, comprising the following steps:

[0043] (1) Weigh a certain amount of alkali slag, dissolve it in water after crushing, stir it into a slurry and pass it through a 100-mesh sieve to remove insoluble matter, let it stand overnight for 12 hours, remove the supernatant and put it in a dryer at 60°C for 10 hours. Get pretreated dehydrated alkali slag.

[0044] (2) Dissolve 12 g of pretreated dehydrated alkali slag in 200 ml of water, stir for 4 hours to form a slurry, add 2 g of ferric oxide powder with a particle size of 100 nm, and continue stirring to obtain a mixed solution.

[0045] (3) After adding sodium carbonate and hydrochloric acid (concentration of 0.1 mol / L) to the mixed solution to adjust the pH value of the mixed solution to 10, fully react for 20 minutes.

[0046] (4) Add 8 g of sodium alginate to the mixed solution, and stir evenly to obtain a gel mixed solution syste...

Embodiment 2

[0052] A heavy metal adsorbent based on alkali slag recycling and a preparation method thereof, comprising the following steps:

[0053] (1) Weigh a certain amount of alkali slag, dissolve it in water after crushing, stir it into a slurry and pass it through a 100-mesh sieve to remove insoluble matter, let it stand overnight for 10 hours, remove the supernatant and put it in a dryer at 60°C for 12 hours. Get pretreated dehydrated alkali slag.

[0054] (2) Take 10 g of the pretreated dehydrated alkali residue and fully dissolve it in 200 ml of water, stir for 4 hours to form a slurry, add 2 g of ferric oxide powder with a particle size of 90 nm, and continue to stir evenly to obtain a mixed solution.

[0055] (3) Add sodium carbonate and hydrochloric acid (concentration: 0.1 mol / L) to the mixed solution to adjust the pH value of the mixed solution to 9, and react fully for 20 minutes.

[0056] (4) Add 6 g of sodium alginate to the mixed solution, and stir evenly to obtain a ge...

Embodiment 3

[0062] A heavy metal adsorbent based on alkali slag recycling and a preparation method thereof, comprising the following steps:

[0063] (1) Weigh a certain amount of alkali slag, dissolve it in water after crushing, stir it into a slurry and pass it through a 200-mesh sieve to remove insoluble matter, let it stand overnight for 16 hours, remove the supernatant and put it in a dryer at 60°C for 12 hours. Obtain pretreatment dehydration alkali slag;

[0064] (2) Dissolve 16 g of the pretreated dehydrated alkali slag in 200 ml of water, stir for 4 hours to form a slurry, add 3 g of ferric oxide powder with a particle size of 90 nm, and continue stirring to obtain a mixed solution.

[0065] (3) Add sodium carbonate and hydrochloric acid (concentration: 0.1 mol / L) to the mixed solution to adjust the pH value of the mixed solution to 9, and react fully for 20 minutes.

[0066] (4) Add 8 g of sodium alginate to the mixed solution, and stir evenly to obtain a gel mixed solution syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com