Monolithic catalyst for removing benzene series at low temperature, and preparation method thereof

A monolithic catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of oxidation by-products, escape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Lattice-doped Cu-MnO 2 Prepared by grinding. Add manganese chloride, potassium permanganate and copper sulfate with a molar ratio of 2:3:(0.07 to 0.3) into the grinder, add 0.5 times the solid volume of water, grind for 2 hours, filter, wash, and dry at 110°C for 12 hours. Lattice-doped Cu-doped MnO obtained by calcination at 500℃ for 6h 2 , respectively recorded as: 0.5% Cu-MnO 2 , 1% Cu-MnO 2 , 2% Cu-MnO 2 .

[0025] XRD and HRTEM analysis prove that copper ions enter MnO 2 lattice.

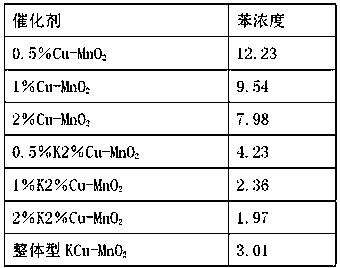

[0026] Catalyst performance tests were carried out in a continuous-flow fixed-bed reactor. Before the catalyst performance test, the catalyst was not treated in any way. The powdered catalyst was pressed into tablets and crushed to make a particle sample of 0.25-0.50 mm. Then, 0.5 g of the particle sample was placed in a glass tube. Under the condition that the humidity is 50%, the air containing 200ppm benzene is introduced, and the wind speed is 2.5m / s. The gas at the outlet o...

Embodiment 2

[0028] Potassium-doped MnO 2 Prepared by ion exchange method. In 1000 g 2% Cu-MnO 2Add 500mL of different concentrations of KCl solution (2.5~10mol / L), at 60 o C to dryness, and then calcined at 400 °C for 24 h to obtain lattice-doped copper and channel-doped potassium MnO 2 , recorded as: 0.5% K-2% Cu-MnO 2 , 1%K-2%Cu-MnO 2 , 2%K-2%Cu-MnO 2 .

[0029] XRD and HRTEM analysis prove that copper ions enter MnO 2 Lattice and K into MnO 2 Pores lead to micro-changes in the channels.

[0030] The catalytic activity test is the same as in Example 1. The results are shown in Table 1.

Embodiment 3

[0032] Doped MnO 2 Preparation of monolithic catalysts. Weigh 1000 g of 2%K-2%Cu-MnO 2 , add 500ml deionized water and 5-50% silica gel binder, stir at 400 rpm for 1-24h, and obtain doped α-MnO 2 slurry. The doped MnO was extracted by vacuum-negative pressure extraction technique 2 The slurry is coated on the pre-treated honeycomb ceramics, and fired at 500 °C for 12 hours to obtain doped MnO 2 Monolithic catalyst, denoted as: monolithic KCu-MnO 2 .

[0033] The performance test of the monolithic catalyst is carried out in the air purifier EN of Huanengtong Group TM Carried on. The three-dimensional of monolithic catalyst is 150*150*40mm 3 , Then pack into the air cleaner, under the condition of low temperature (100° C.) and relative humidity of 50%, feed the air containing 200 ppm benzene, and the wind speed is 2.5m / s. Agilent 7890A gas chromatograph was used to detect the concentration of the outlet gas. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com