BDD composite electrode material and preparation method for same, BDD composite electrode

A boron-doped diamond and composite electrode technology, which is applied in the field of electrocatalytic oxidation electrode material preparation, can solve the problems of poor photocatalytic performance of BDD electrodes, poor photocatalytic performance, and poor performance of electrode materials, so that carrier transport is more likely to occur, The effect of simplifying the preparation method and improving the Hall mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

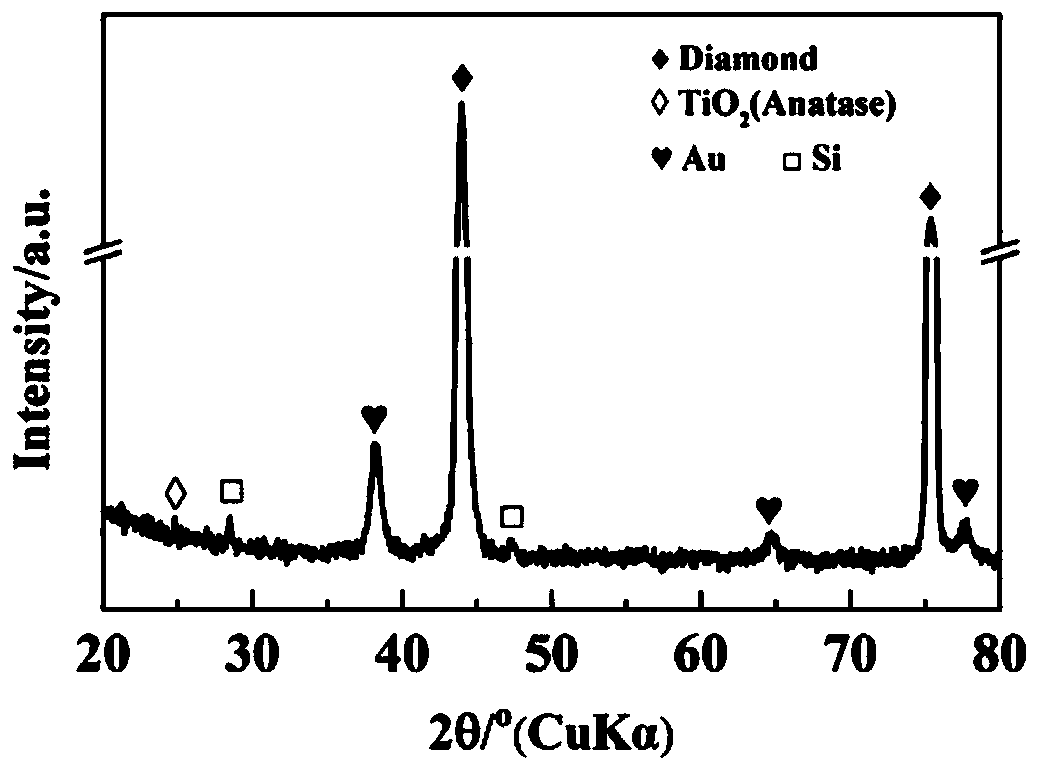

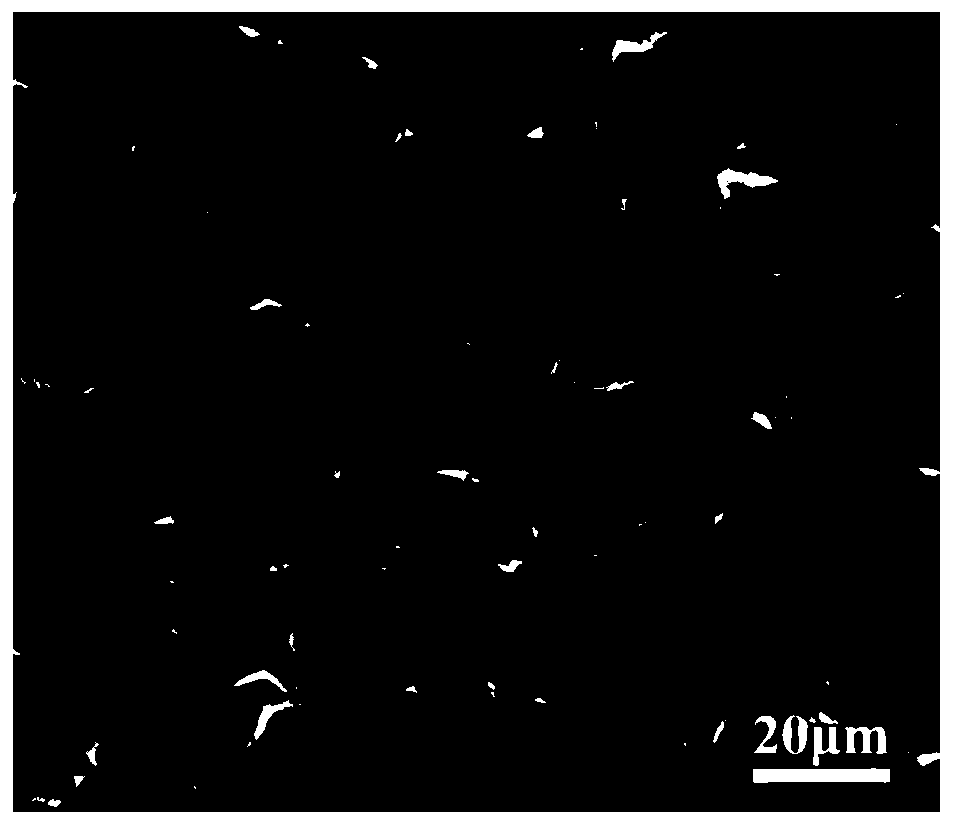

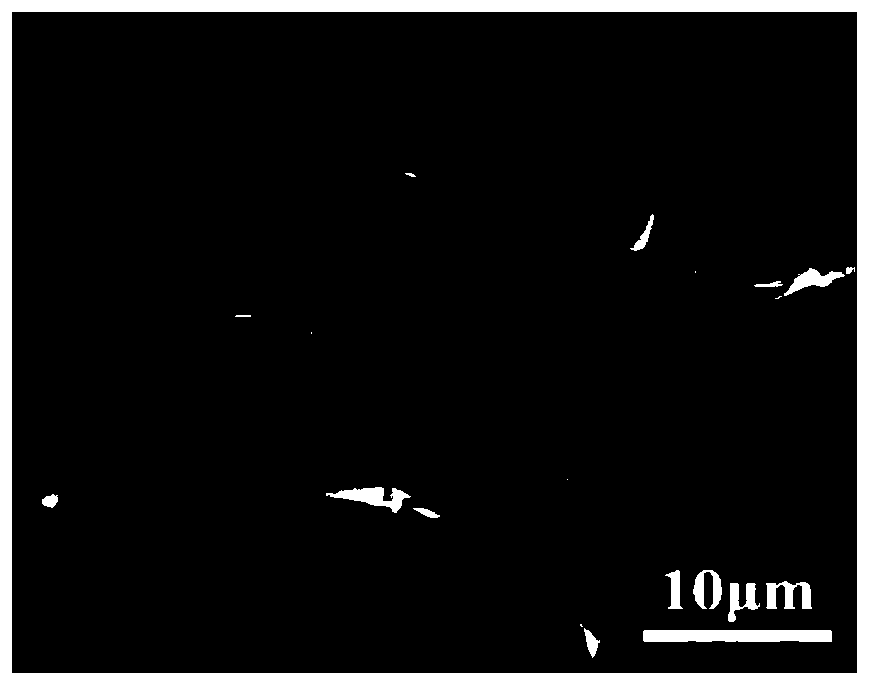

[0035] The boron-doped diamond composite electrode material of this embodiment includes a BDD layer as a substrate, an Au layer arranged on the BDD layer, and a TiO layer arranged on the Au layer 2 Floor.

[0036] Two, the embodiment of the preparation method of boron-doped diamond composite electrode material, wherein, BDD is loaded on the silicon substrate (silicon-based BDD), and silicon-based BDD is purchased from Zhengzhou Abrasive Grinding Research Institute Co., Ltd., and existing There are techniques for preparation, such as preparation by microwave plasma chemical vapor deposition method.

Embodiment 2

[0038] The preparation method of the boron-doped diamond composite electrode material of the present invention is to illustrate the preparation of the boron-doped diamond composite electrode material of embodiment 1, specifically comprising the following steps:

[0039]1) Use acetone, absolute ethanol, and deionized water to ultrasonically clean the BDD, and use an ion sputtering instrument to sputter Au on the surface of the BDD to obtain an Au / BDD composite material containing an Au layer; the sputtering target for sputtering Au is an Au target , the sputtering current is 4mA, and the sputtering time is 90s;

[0040] 2) Electrophoretic deposition is performed on the Au layer of the Au / BDD composite material, and the electrophoretic solution for electrophoretic deposition is TiO 2 Sol, electrophoretic deposition after heat treatment to TiO 2 Sol conversion to TiO 2 , that is, TiO is obtained on the surface of the Au layer 2 layer; repeated electrophoretic deposition and he...

Embodiment 3

[0042] The preparation method of the boron-doped diamond composite electrode material of the present embodiment comprises the following steps:

[0043] 1) Use acetone, absolute ethanol, and deionized water to ultrasonically clean the BDD, and use an ion sputtering instrument to sputter Au on the surface of the BDD to obtain an Au / BDD composite material containing an Au layer; the sputtering target for sputtering Au is an Au target , the sputtering current is 4mA, and the sputtering time is 60s;

[0044] 2) Electrophoretic deposition is performed on the Au layer of the Au / BDD composite material, and the electrophoretic solution for electrophoretic deposition is TiO 2 Sol, electrophoretic deposition after heat treatment to TiO 2 Sol conversion to TiO 2 , that is, TiO is obtained on the surface of the Au layer 2 layer; repeated electrophoretic deposition and heat treatment, the total number of treatments is 3 times; TiO 2 The sol is prepared by hydrolysis of organic titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hall mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com