Electrified constant-temperature test paper base material and preparation method thereof

A technology of test paper and constant temperature, applied in chemical instruments and methods, papermaking, paper coating, etc., can solve problems such as no solution reported in literature, and achieve improvement of poor dispersion, low process maturity, and low environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

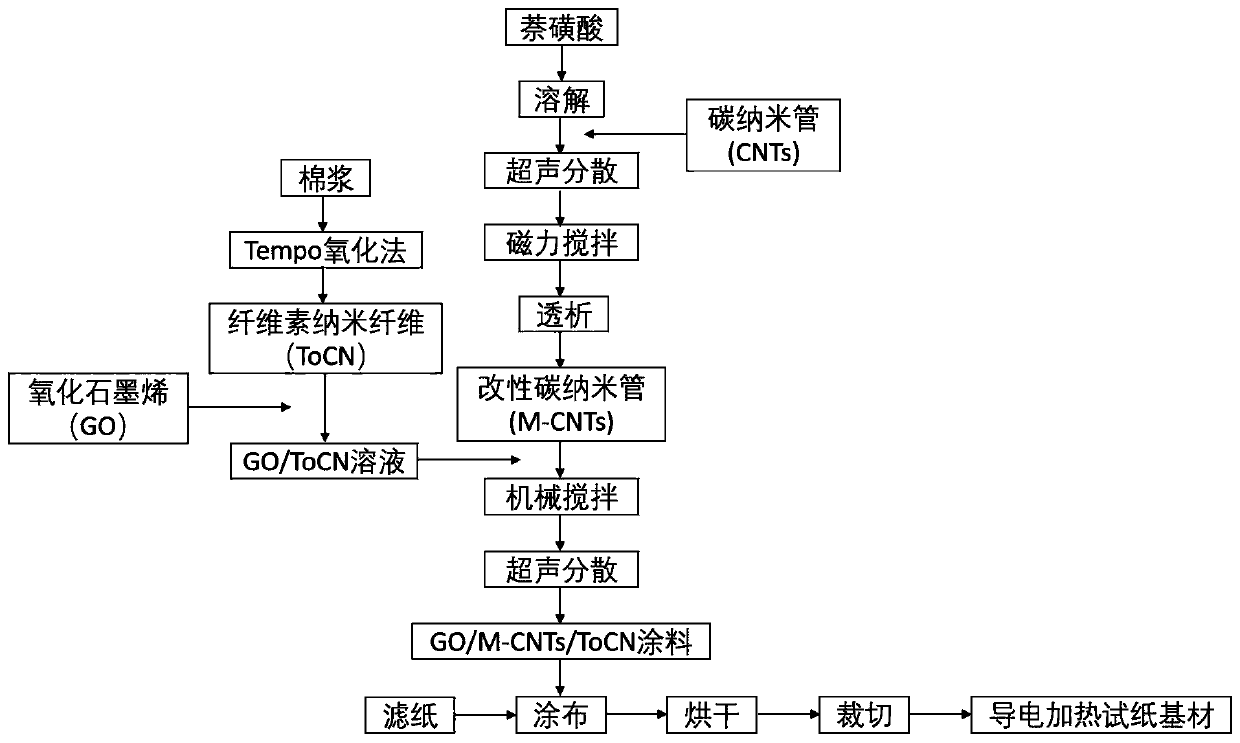

Method used

Image

Examples

example 1

[0051] Preparation of ToCN (cellulose nanofibers): prepare 100 mL of cotton pulp suspension with a mass concentration of 1%, add 0.1 g of sodium bromide and 0.02 g of tempo (2,2,6,6-tetramethylpiperidinyloxy radical ) reagent, after stirring evenly, add 5 mL of sodium hypochlorite solution with a concentration of 0.15 mol / L, after mixing, use a dilute hydrochloric acid solution with a concentration of 0.1 mol / L to adjust the pH value of the mixed solution to 10 to obtain a mixed reaction solution; then The mixed reaction solution was placed in an ice-water bath and stirred for 6 hours. During the stirring process, NaOH solution with a concentration of 0.1 mol / L was continuously added dropwise to maintain the pH value of the mixed reaction solution at 10. After the reaction, a 1% ToCN solution can be obtained.

[0052] CNTs (carbon nanotube) modification: dissolve naphthalenesulfonic acid in water, and control the concentration of naphthalenesulfonic acid at 20g / L. The carbon ...

Embodiment 2

[0057] Preparation of ToCN: Prepare 100 mL of cotton pulp suspension with a mass concentration of 1%, add 0.1 g of sodium bromide and 0.02 g of tempo (2,2,6,6-tetramethylpiperidinyl oxygen free radical) reagent, stir well and then Add 5 mL of sodium hypochlorite solution with a concentration of 0.15 mol / L, and after mixing, adjust the pH value of the mixed solution to 10 with a diluted hydrochloric acid solution with a concentration of 0.1 mol / L to obtain a mixed reaction solution; then place the mixed reaction solution in The reaction was stirred in an ice-water bath for 6 h, and NaOH solution with a concentration of 0.1 mol / L was continuously added dropwise during the stirring process to maintain the pH value of the mixed reaction solution at 10. After the reaction, a 1% ToCN solution can be obtained.

[0058] CNTs modification: dissolve naphthalenesulfonic acid in water, and control the concentration of naphthalenesulfonic acid at 30g / L. The carbon nanotubes were added to ...

Embodiment 3

[0063] Preparation of ToCN: Prepare 100 mL of cotton pulp suspension with a mass concentration of 1%, add 0.1 g of sodium bromide and 0.02 g of tempo (2,2,6,6-tetramethylpiperidinyl oxygen free radical) reagent, stir well and then Add 5 mL of sodium hypochlorite solution with a concentration of 0.15 mol / L, and after mixing, adjust the pH value of the mixed solution to 10 with a diluted hydrochloric acid solution with a concentration of 0.1 mol / L to obtain a mixed reaction solution; then place the mixed reaction solution in The reaction was stirred in an ice-water bath for 6 h, and NaOH solution with a concentration of 0.1 mol / L was continuously added dropwise during the stirring process to maintain the pH value of the mixed reaction solution at 10. After the reaction, a 1% ToCN solution can be obtained.

[0064] CNTs modification: Dissolve naphthalenesulfonic acid in water, and control the concentration of naphthalenesulfonic acid at 40g / L. The carbon nanotubes were added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com