Method for treating sludge hydrolysate by fungi and recovering mycothalli

A hydrolyzate and fungus technology, which is applied in the pyrolysis treatment of sludge, fungi, and sludge treatment, etc., can solve the problems of low utilization value of recovered methane resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

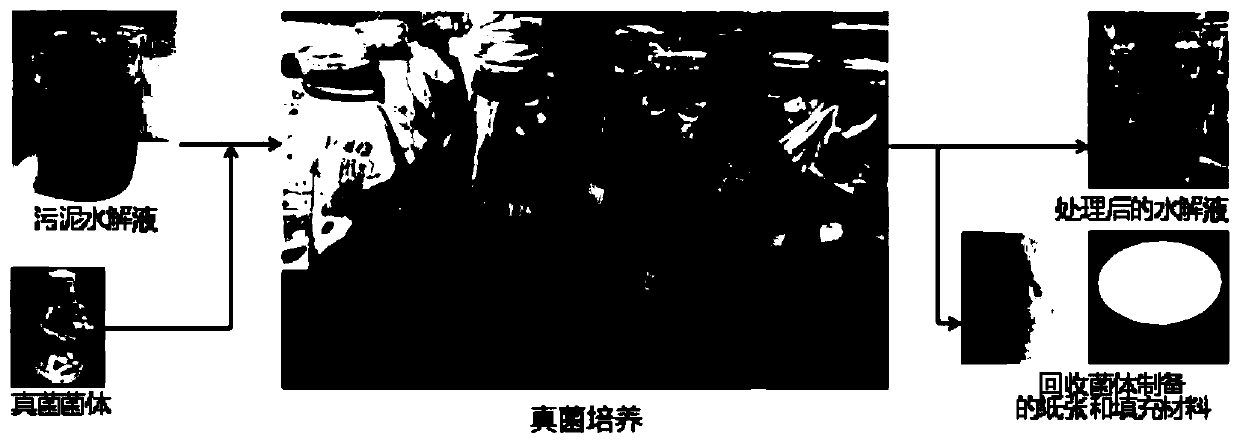

[0032] see figure 1 , the present embodiment provides a method of using fungi to treat sludge hydrolyzate and reclaim fungal cells. The specific steps are as follows: take the remaining sludge with a SS concentration (suspended solid concentration) of 15g / L and place it in an autoclave. Under the conditions of 160°C and 200rpm, thermally hydrolyze for 60 minutes, pour out the sludge hydrolyzate after the temperature drops to room temperature, and filter it with a glass fiber membrane to obtain the sludge hydrolyzate. Take the sludge hydrolyzate and place it under high-pressure steam sterilization at 116°C for 20 minutes. After cooling down to room temperature, inoculate Aspergillus niger in the sludge hydrolyzate at an inoculation amount of 5% volume ratio in the ultra-clean workbench, and then place it at 30°C. , 150rpm constant temperature shaking incubator culture. Samples were taken every 12 to 24 hours to measure the COD concentration and fungal cell concentration of the...

Embodiment 2

[0035] The steps of this embodiment are the same as those of Example 1, except that the inoculated strain is Rhizopus oryzae.

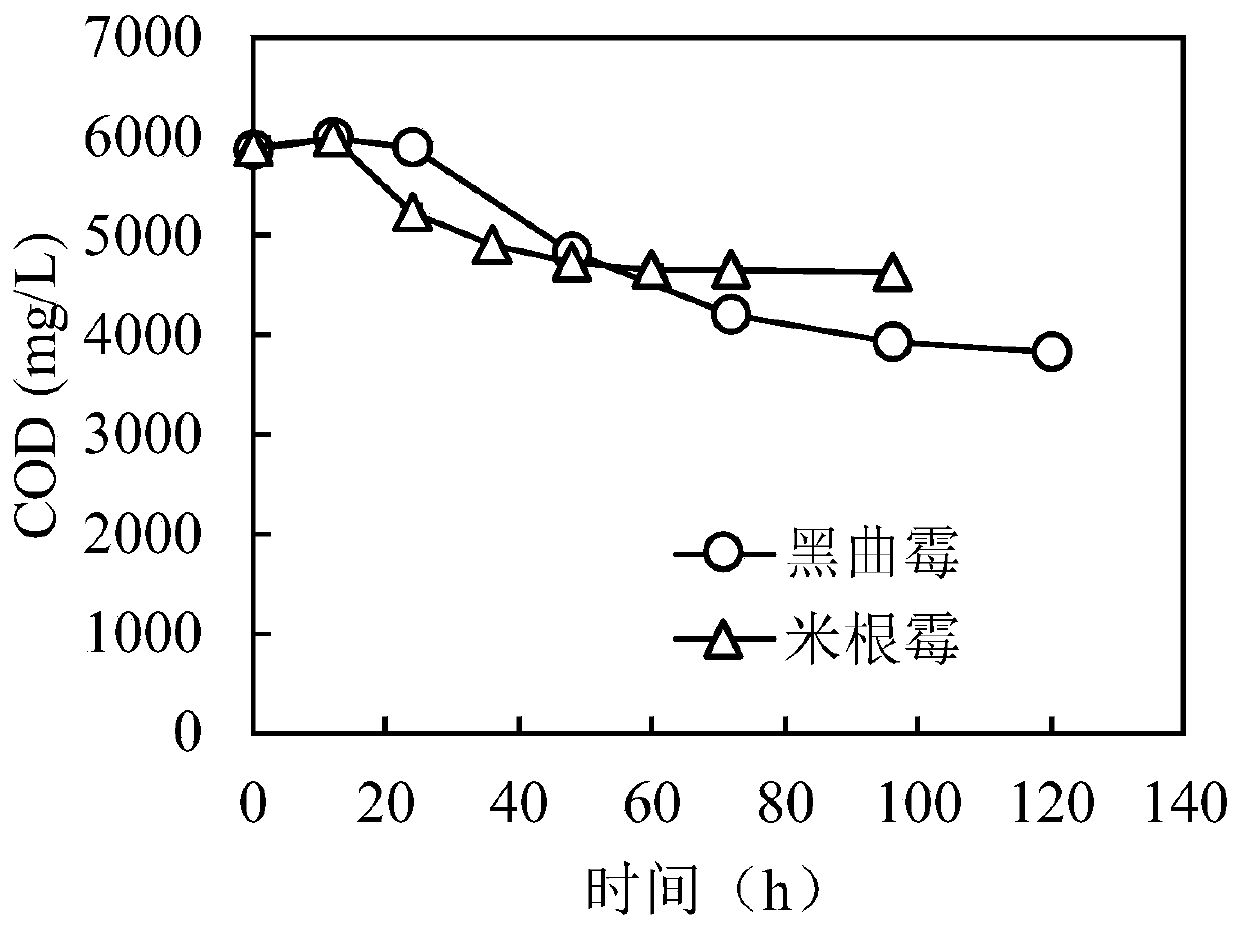

[0036] The COD concentration of the sludge hydrolyzate inoculated with Aspergillus niger and the COD concentration of the sludge hydrolyzate inoculated with Rhizopus oryzae were measured respectively in embodiment 1, the results are as follows image 3shown. The results showed that after the inoculation of Aspergillus niger and Rhizopus oryzae, the COD concentration of the sludge hydrolyzate decreased gradually, and the COD concentration reached stability at 120h and 60h respectively after inoculation of Aspergillus niger and Rhizopus oryzae, and the COD removal rate was 35% respectively and 22%, the experimental results show that the fungi can degrade the organic matter in the sludge hydrolyzate. The growth of fungi in sludge hydrolyzate is as follows: Figure 4 As shown, after the inoculation of Aspergillus niger and Rhizopus oryzae, the concentra...

Embodiment 3

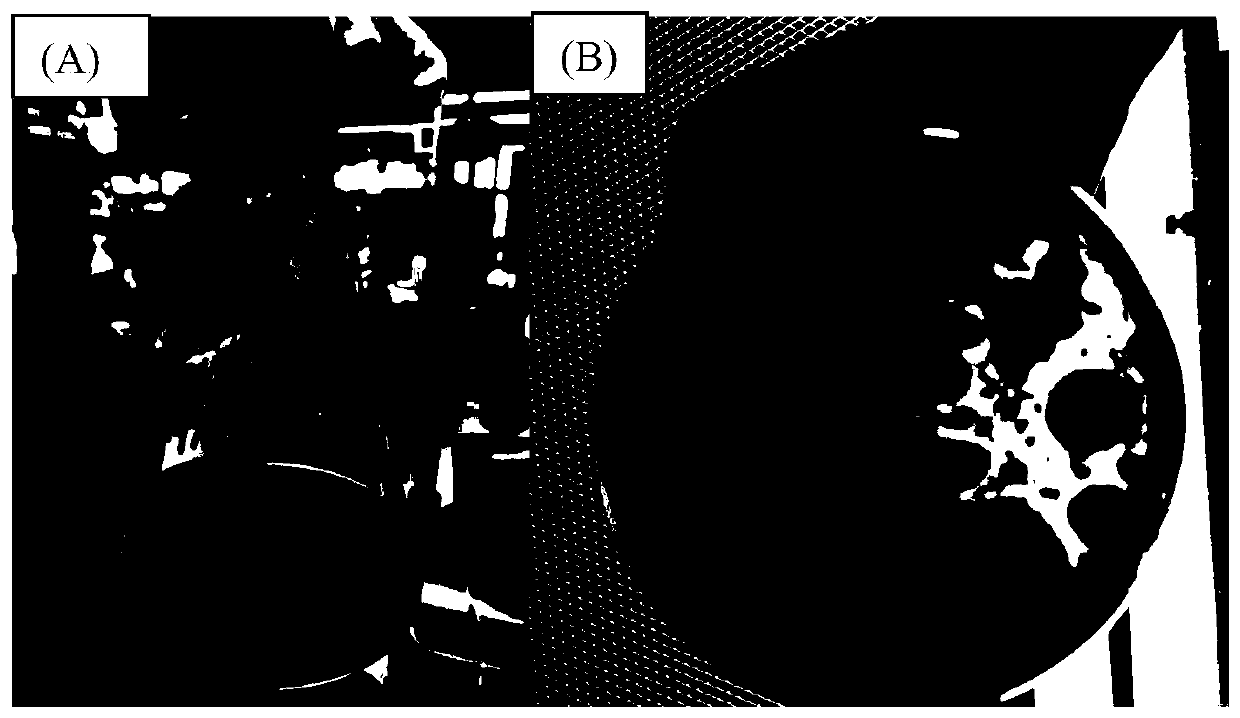

[0039] Take the remaining sludge with SS concentration (suspended solid concentration) of 30g / L and place it in a high-pressure reactor, and heat hydrolyze it at 160°C and 200rpm for 60min. Fibrous membrane filtration to obtain sludge hydrolyzate. Take the sludge hydrolyzate and place it under high-pressure steam sterilization at 116°C for 20 minutes. After cooling down to room temperature, inoculate Aspergillus niger in the sludge hydrolyzate at an inoculation amount of 5% volume ratio in the ultra-clean workbench, and then place it at 30°C. , 150rpm constant temperature shaking incubator culture. Samples were taken every 12 to 24 hours to measure the COD concentration and fungal cell concentration of the sludge hydrolyzate, and the cultivation was stopped after reaching a stable value. The treated sludge hydrolyzate and fungal cells are separated by filtration, and the recovered mycelium is dispersed and reshaped to make the mycelia cross-linked together to prepare thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com