Clean and efficient cane juice clarification method by sulfurous acid method

A sulfurous acid method, high-efficiency technology, applied in separation methods, chemical instruments and methods, sucrose production, etc., can solve problems such as large residue, incomplete reaction, fouling of equipment and pipelines, and reduce heat transfer efficiency and production Efficiency, the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

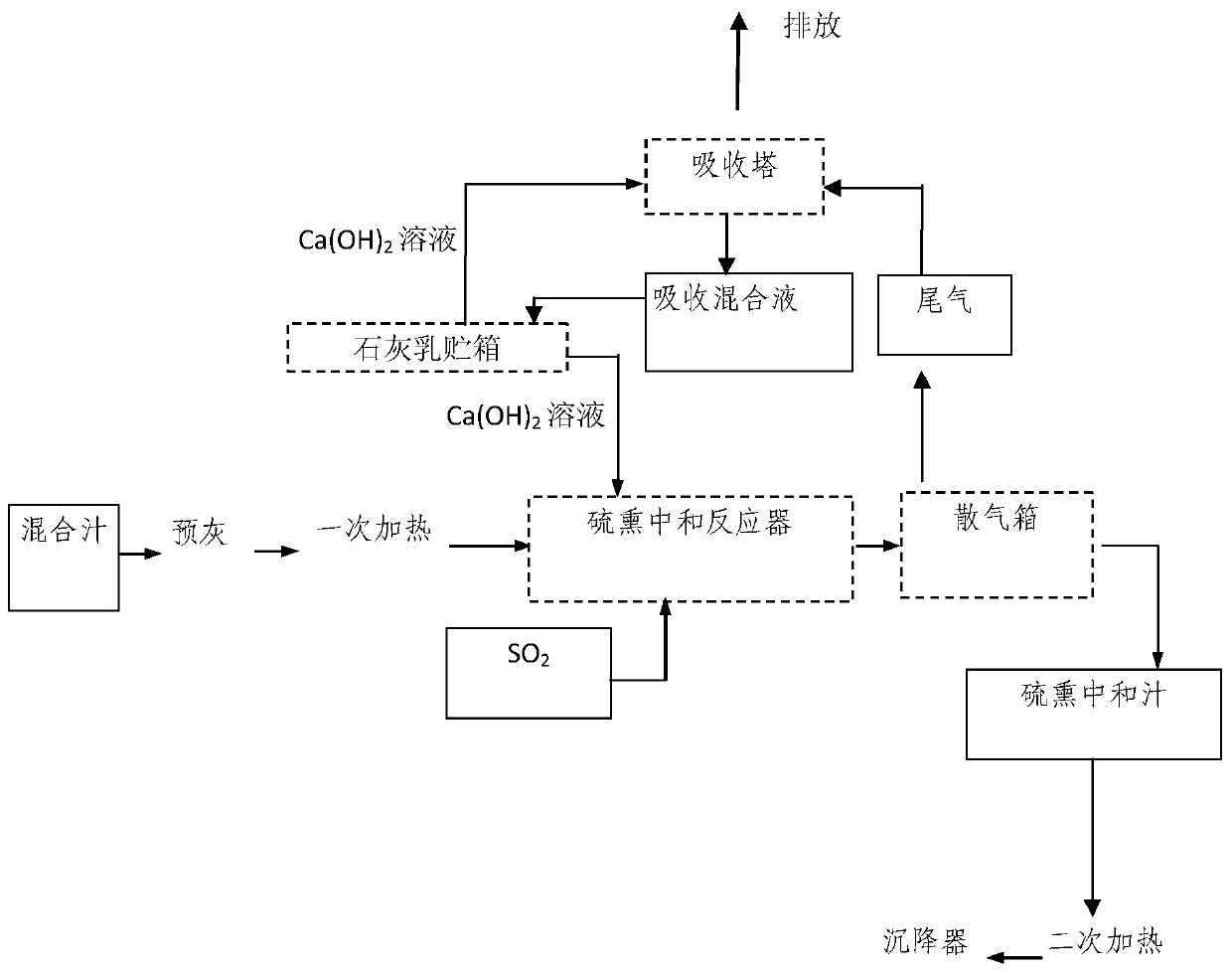

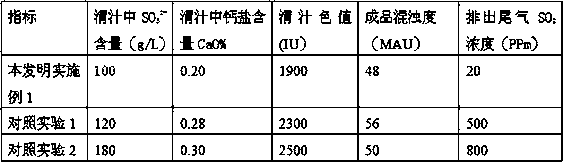

[0023] Example 1: A clean and efficient clarification method for sugarcane juice by sulfite method. After the mixed juice is pre-ashed and heated once, it enters the sulfur fumigation neutralization reactor for sulfur fumigation neutralization reaction, and simultaneously feeds the sulfur fumigation neutralization reactor SO 2 Gas (concentration 8-17%, 2000m 3 / h), add lime milk solution from the lime milk storage tank to the sulfur fumigation neutralization reactor (lime milk solution 8 Baume degree, 50m 3 / h), the gas-liquid mixture from the sulfur fumigation neutralization reactor is passed into the diffuser box, and the tail gas from the diffuser box is passed into the absorption device, and the lime milk solution is introduced into the tail gas from the lime milk storage tank at the same time in the absorption device SO 2 For absorption, the volume ratio of lime milk solution and tail gas into the absorption device is 2.5% (that is, the tail gas is passed through 2000m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com