Mulberry and fructus lycii ferment and preparation method thereof

A wolfberry enzyme and mulberry technology, applied to bacteria, bifidobacteria, and food science used in food preparation, can solve problems such as difficult decomposition and waste, and achieve the effects of low production cost, simple production equipment, and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

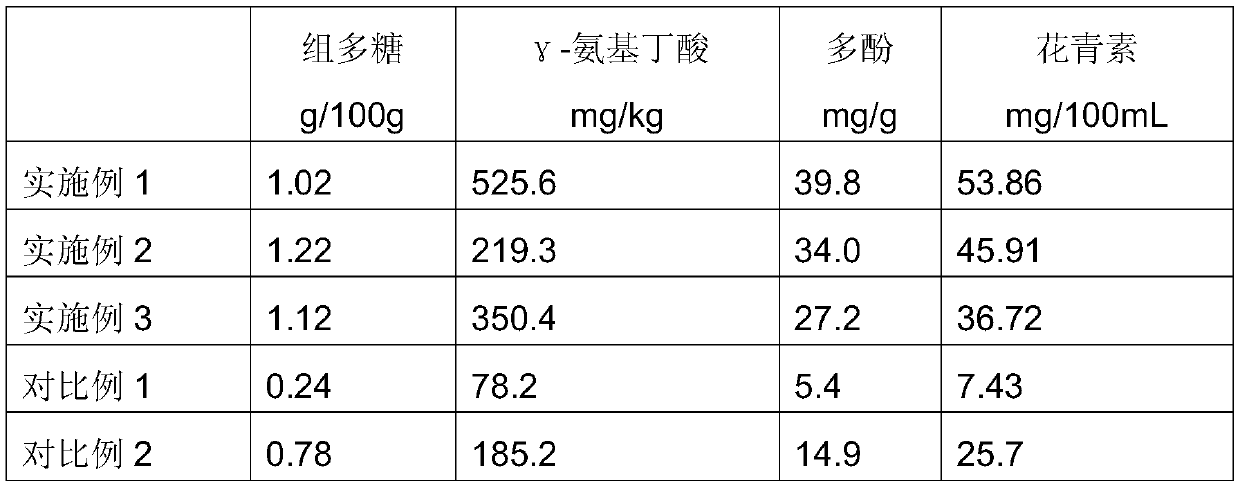

Examples

Embodiment 1

[0025] A preparation method of mulberry wolfberry enzyme, comprising the following steps:

[0026] 1) Rinse the dried wolfberry until the epidermis is free of dirt, soak in water for 1 hour; clean the fresh mulberries;

[0027] 2) Mix the mulberries and dried goji berry at a weight ratio of 8:1, add pure water and beat, the weight ratio of the mixed fruit to water is 1:1; use a high-speed masher to beat, and crush it into a particle size of 0.1~ The 0.3cm fragments are then finely ground with a colloid mill, and the slurry is repeatedly passed through the colloid mill 3 times to completely break up the contained seeds, so that the particle size is controlled at 10-30 μm.

[0028] 3) Add citric acid in the fruit pulp as a pH regulator, add 0.1% compound enzyme of the total weight of the fruit pulp, and enzymolyze it; the compound enzyme is a compound of cellulase, hemicellulase, ligninase and pectinase Enzyme; the weight ratio of cellulase, hemicellulase, ligninase and pectina...

Embodiment 2

[0033] A preparation method of mulberry wolfberry enzyme, comprising the following steps:

[0034] 1) Rinse the dried wolfberry until the epidermis is free of dirt, soak in water for 1.5 hours; clean the fresh mulberries;

[0035] 2) Mix the mulberries and dried goji berry at a weight ratio of 15:1, add pure water and beat, the weight ratio of the mixed fruit to water is 1:1.5; use a high-speed masher to beat, and crush it into a particle size of 0.1~ The 0.3cm fragments are then finely ground with a colloid mill, and the slurry is repeatedly passed through the colloid mill 3 times to completely break up the contained seeds, so that the particle size is controlled at 10-30 μm.

[0036] 3) Add citric acid to the fruit pulp as a pH regulator, add 0.1% compound enzyme of the total weight of the fruit pulp, and perform enzymatic hydrolysis; the compound enzyme is a compound of cellulase, hemicellulase, ligninase and pectinase Enzyme; the weight ratio of cellulase, hemicellulase, ...

Embodiment 3

[0041] A preparation method of mulberry wolfberry enzyme, comprising the following steps:

[0042] 1) Rinse the dried wolfberry until the epidermis is free of dirt, soak in water for 2 hours; clean the fresh mulberries;

[0043] 2) Mix the mulberries and dried goji berry at a weight ratio of 10:1, add pure water and beat, the weight ratio of the mixed fruit to water is 1:2; use a high-speed masher to beat, and crush it into a particle size of 0.1~ The 0.3cm fragments are then finely ground with a colloid mill, and the slurry is repeatedly passed through the colloid mill 3 times to completely break up the contained seeds, so that the particle size is controlled at 10-30 μm.

[0044] 3) Add citric acid in the fruit pulp as a pH regulator, add 0.1% compound enzyme of the total weight of the fruit pulp, and enzymolyze it; the compound enzyme is a compound of cellulase, hemicellulase, ligninase and pectinase Enzyme; the weight ratio of cellulase, hemicellulase, ligninase and pecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com