Preparation method and application of Ce/N co-doped TiO2/acid-leached diatomite composite spheres

A technology of diatomite and co-doping, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

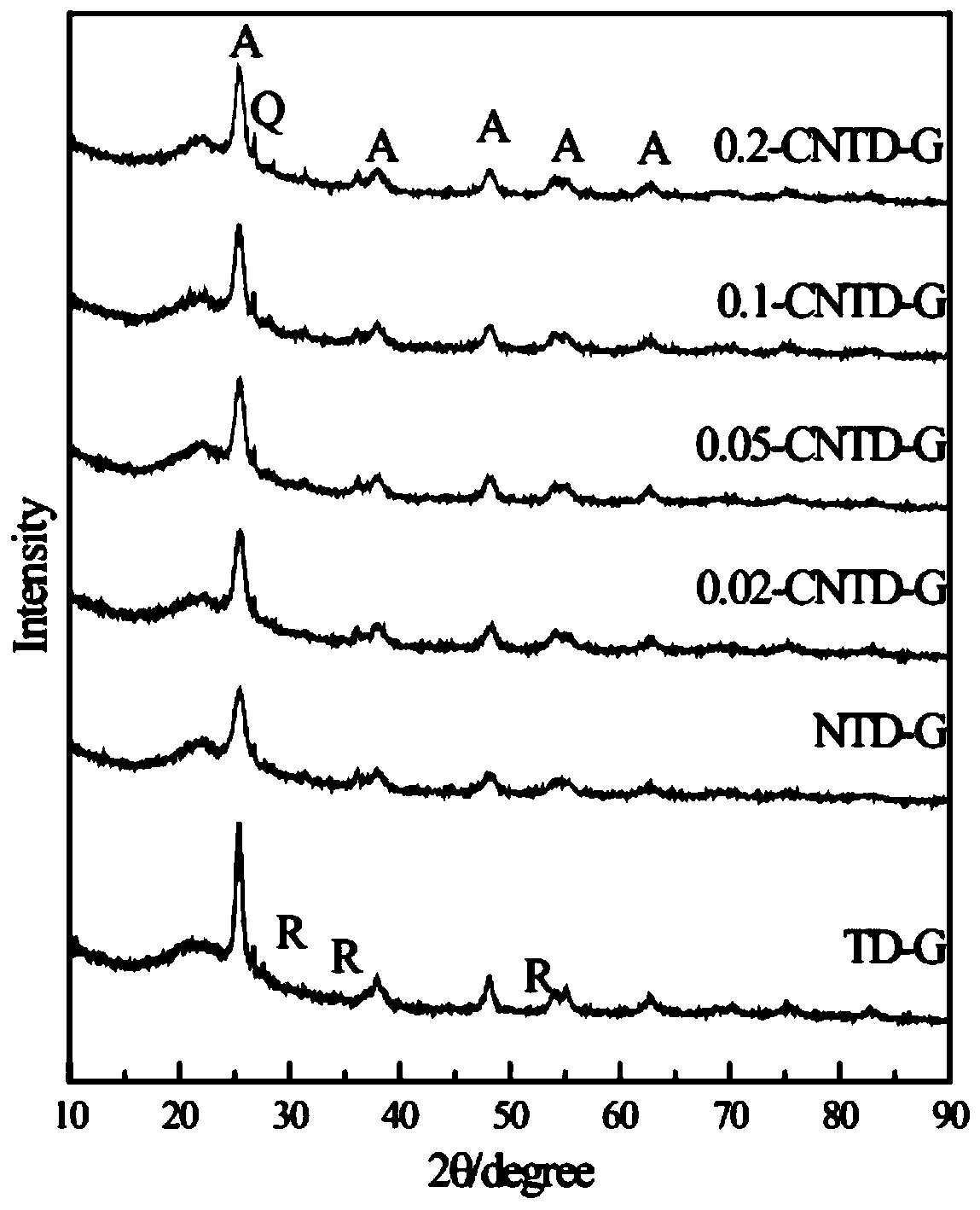

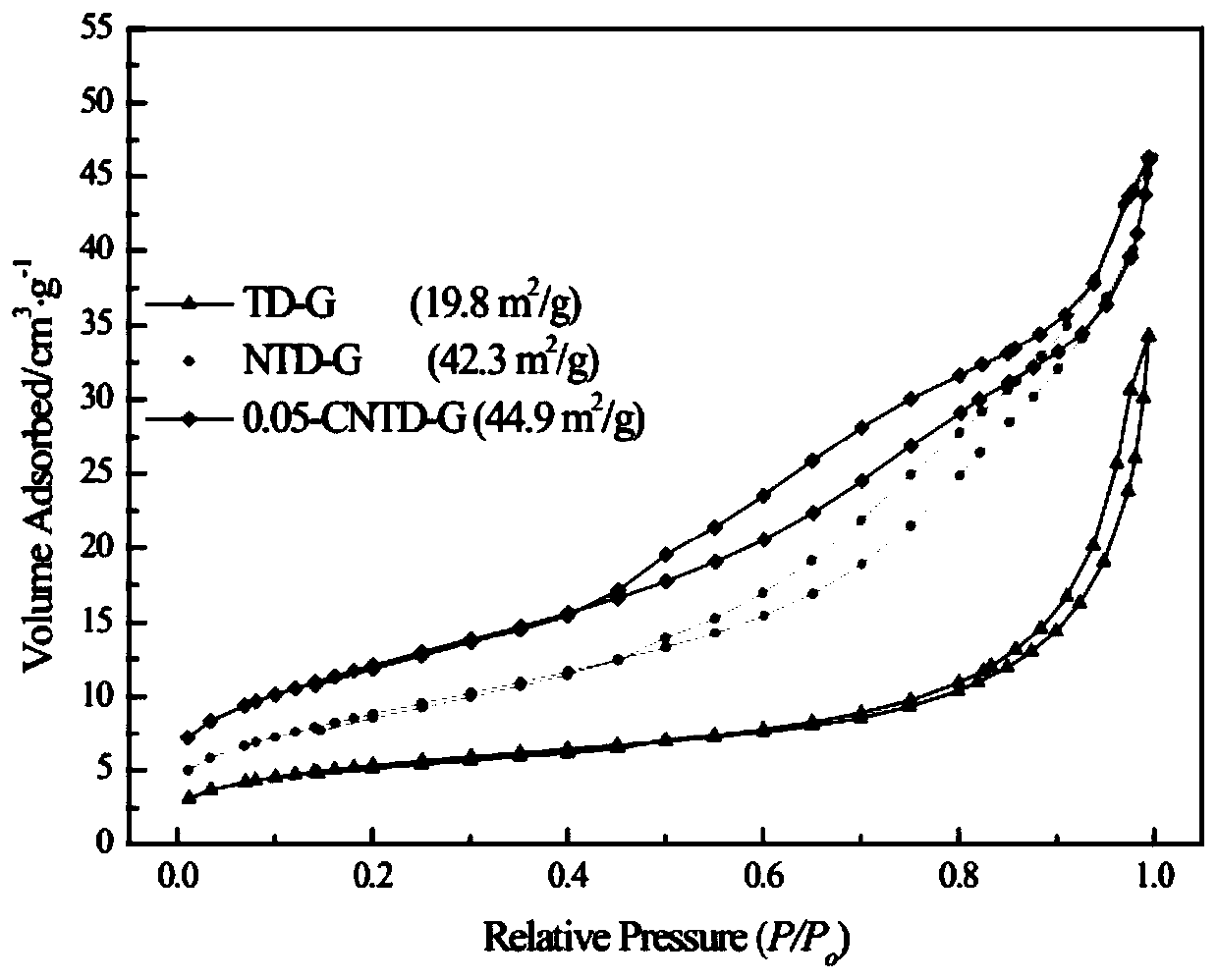

[0037] Example 1 Ce / N co-doped TiO 2 / Acid dipped diatomite composite sphere (CNTD-G for short)

[0038] (1) Preparation of CNTD-G with different Ce doping amounts

[0039] 1) Acid soaking diatomite preparation method: Weigh diatomite raw soil, according to the solid-to-liquid ratio of 1.0g:2.5mL, add dilute sulfuric acid solution with a concentration of 15wt%, and mix the diatomite raw soil and dilute sulfuric acid evenly , keep the mechanical stirring state at room temperature for 24 hours. Afterwards, it was washed with deionized water until neutral, and dried at 80° C. to obtain acid-leached diatomite treated with dilute sulfuric acid.

[0040] 2) Mix 5.0g of acid soaked diatomite with 70.0mL of absolute ethanol and 5.0mL of glacial acetic acid, stir mechanically for 30min, then add 8.0mL of tetra-n-butyl titanate and 1.0mL of ethylene glycol amine dropwise, and continue stirring A suspension was formed.

[0041] Another 2.8g of urea, 24.0mL of absolute ethanol and 8.0...

Embodiment 2

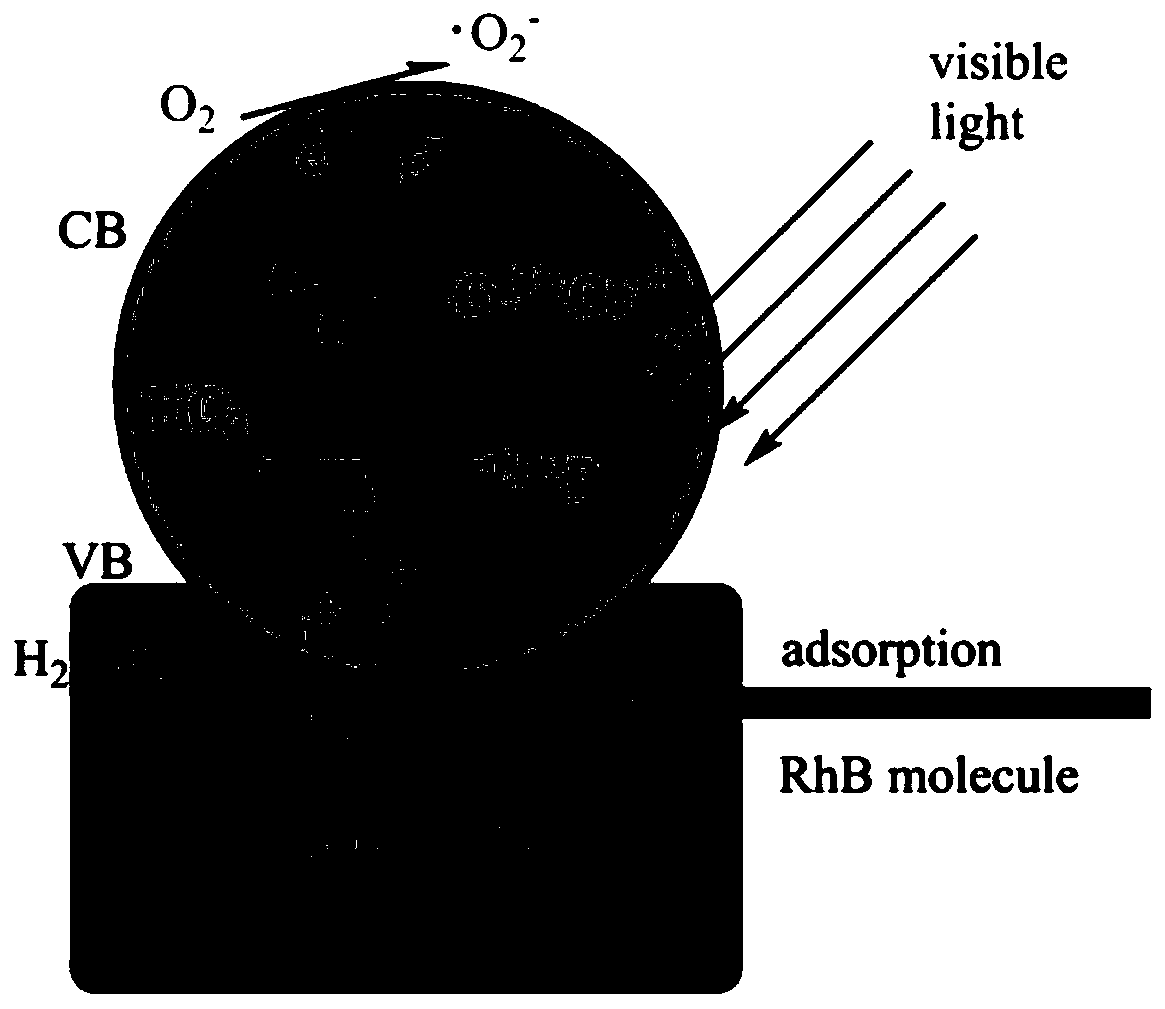

[0073] Example 2 Ce / N co-doped TiO 2 / Application of acid-leached diatomite composite spheres in the degradation of organic dyes under visible light

[0074] Using rhodamine B as the target degradation product, the visible light catalytic activity of co-doped composite spheres was investigated, and the photodegradation process was as follows: figure 1 .

[0075] The method is as follows: 1.0 g of CNTD-G with different Ce-doped amounts prepared in Example 1 was added to 200.0 mL of rhodamine B solution with a concentration of 0.01 g / L, and the dark adsorption process was carried out for 30 min to make the whole system When the dynamic adsorption equilibrium is reached, it is then placed under visible light (xenon lamp) with a power of 150W for photocatalytic degradation for 180min.

[0076] 1. Research on visible light catalytic activity

[0077] Rhodamine B was used as the target degradation product to examine the visible light catalytic activity of co-doped composite spheres...

Embodiment 3

[0083] Example 3 Ce / N co-doped TiO 2 / Application of acid-leached diatomite composite spheres in the degradation of polycyclic substances under visible light

[0084] Using tetracycline hydrochloride (TC) as the target degradation product, the visible light catalytic activity of co-doped composite spheres was investigated.

[0085] The method is as follows: add the CNTD-G prepared in Example 1 to the TC aqueous solution with an initial concentration of 20.0 mg / L and a pH value of 6, and the addition amount is 5.0 g / L. First, carry out a dark adsorption process for 30 minutes, so that the whole system reaches Dynamic adsorption equilibrium, and then placed under visible light (xenon lamp) with a power of 150W for photocatalytic degradation for 240min.

[0086] 1. Degradation of TC by co-doped composite spheres CNTD-G with different Ce doping amounts

[0087] Figure 12 It is the corresponding TOC analysis result of the visible light degradation experiment of co-doped sphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com