Long wafer boat and preparation process

A preparation process and crystal growth technology, applied in the field of crystal boat growth and preparation process, can solve the problems of inability to use conventional welding, cutting and drilling damage, high brittleness of silicon carbide, etc., so as to improve the preparation efficiency and yield, and improve the yield , the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

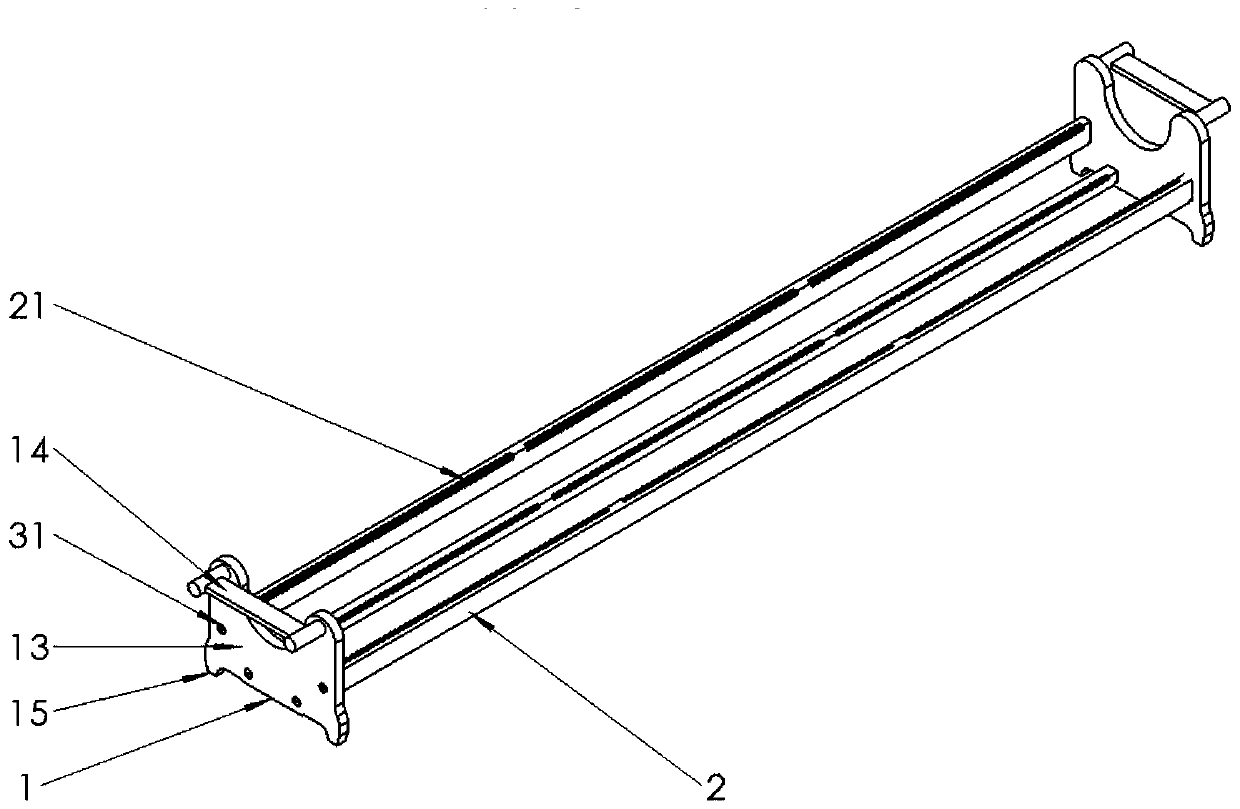

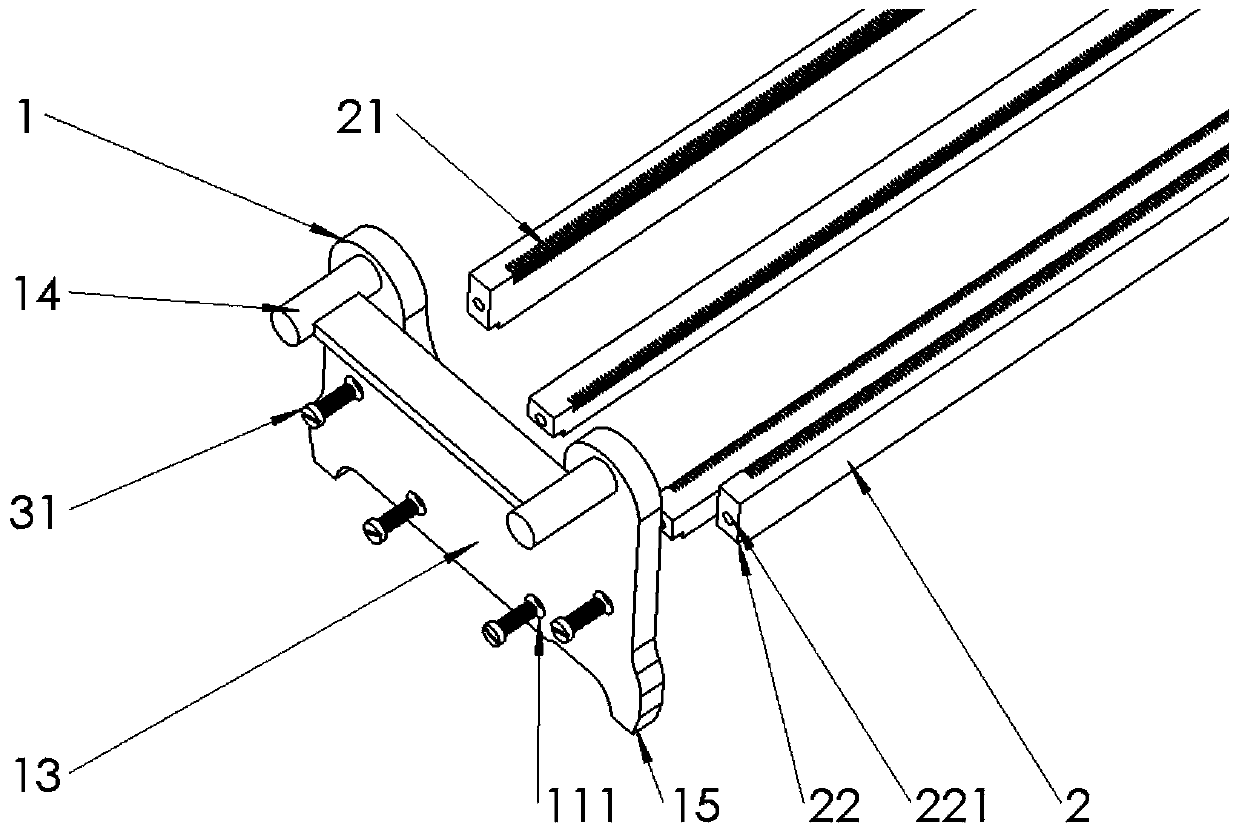

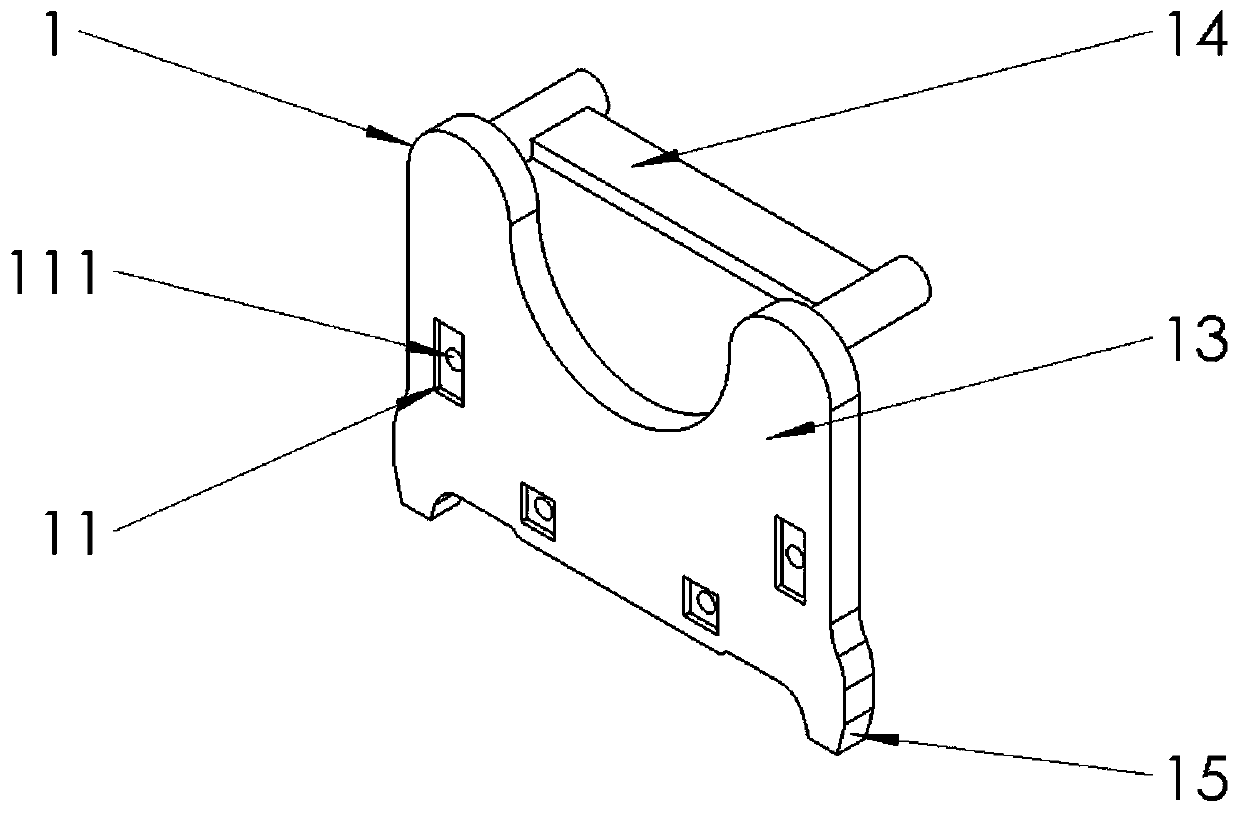

[0081] refer to figure 1 , the present embodiment provides a crystal growth boat, comprising a baffle 1 and a placement column 2, the placement column 2 is provided with a wafer groove 21, the two ends of the placement column 2 are connected to the baffle 1, and the baffle 1 Both the placement column 2 are made of silicon carbide, and the baffle plate 1 and the placement column 2 are connected by mortise and tenon.

[0082] By adopting the above scheme, the wafer groove 21 is used to store wafers, and by utilizing the excellent characteristics of silicon carbide, the shape of the long crystal boat is reduced, the heat is reduced, and the heat conduction is good, and a larger carrying capacity can be set to improve the carrying capacity of the wafers. The production efficiency and yield rate in the high-temperature preparation process; however, due to the high brittleness of silicon carbide, the overall firing process is cumbersome, the failure rate is high, and the cost is hig...

Embodiment 2

[0094] refer to Figure 5 , the present embodiment provides a crystal growth boat, comprising a baffle 1 and a placement column 2, the placement column 2 is provided with a wafer groove 21, the two ends of the placement column 2 are connected to the baffle 1, and the baffle 1 Both the placement column 2 are made of silicon carbide, and the baffle plate 1 and the placement column 2 are connected by mortise and tenon.

[0095] By adopting the above scheme, the wafer groove 21 is used to store wafers, and by utilizing the excellent characteristics of silicon carbide, the shape of the long crystal boat is reduced, the heat is reduced, and the heat conduction is good, and a larger carrying capacity can be set to improve the carrying capacity of the wafers. The production efficiency and yield rate in the high-temperature preparation process; however, due to the high brittleness of silicon carbide, the overall firing process is cumbersome, the failure rate is high, and the cost is hi...

Embodiment 3

[0109] refer to Figure 9 , the present embodiment provides a crystal growth boat, comprising a baffle 1 and a placement column 2, the placement column 2 is provided with a wafer groove 21, the two ends of the placement column 2 are connected to the baffle 1, and the baffle 1 Both the placement column 2 are made of silicon carbide, and the baffle plate 1 and the placement column 2 are connected by mortise and tenon.

[0110] By adopting the above scheme, the wafer groove 21 is used to store wafers, and by utilizing the excellent characteristics of silicon carbide, the shape of the long crystal boat is reduced, the heat is reduced, and the heat conduction is good, and a larger carrying capacity can be set to improve the carrying capacity of the wafers. The production efficiency and yield rate in the high-temperature preparation process; however, due to the high brittleness of silicon carbide, the overall firing process is cumbersome, the failure rate is high, and the cost is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com