Recovery and treatment method of all straw wastes in vegetable production process

A production process, recycling technology, applied in the direction of bio-organic part treatment, fertilizer mixture, organic fertilizer preparation, etc., can solve the problems of slow decay and decomposition of straw, low efficiency of waste utilization, etc., to promote mass reproduction and improve resources Utilization rate, effect of improving soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

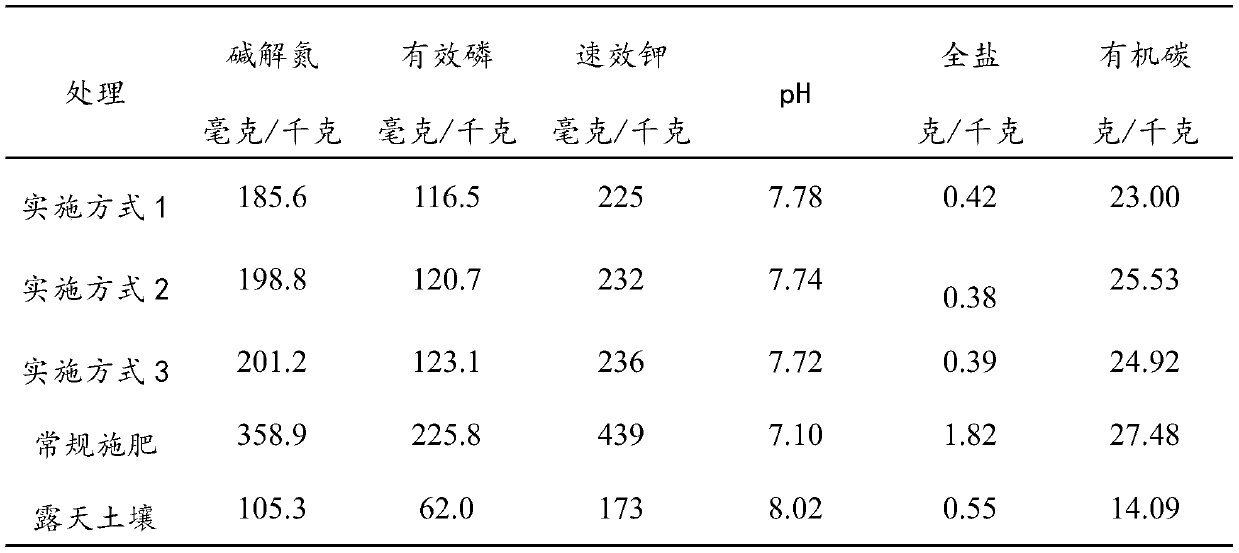

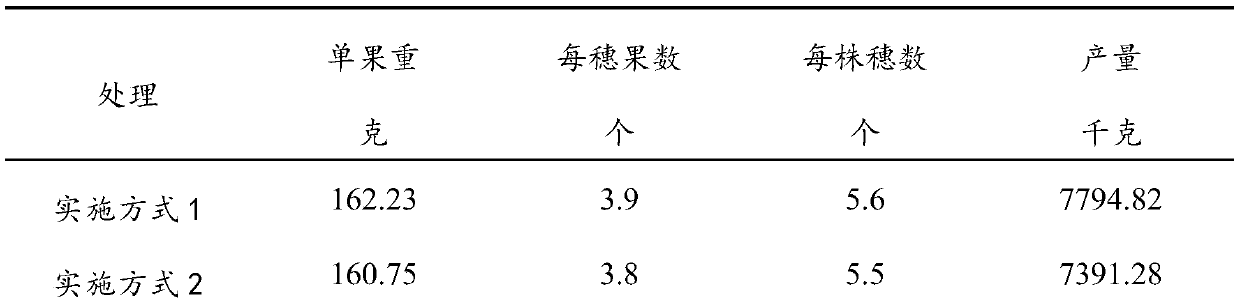

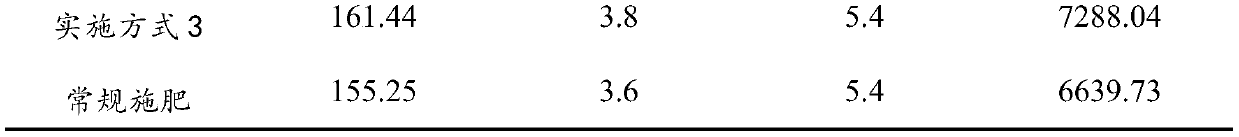

Embodiment approach 1

[0043] This embodiment provides a method for recycling and processing all straw waste in the vegetable production process, which includes the following steps:

[0044] S1 collects and cuts the waste produced by each pruning and forking of fresh vegetable stalks and each flower thinning and fruit thinning to 3 cm in each section to obtain waste A;

[0045] S2 all joins the water of the waste material A of 72 mass parts, the brown sugar of 216 mass parts, 730 mass parts in the plastic barrel and mixes evenly, then adds the effective number of viable bacteria in the live bacteria preparation in the plastic barrel to be 1,000,000,000 / The 0.8 mass parts of gram live yeast preparation and the effective viable count in the live bacteria preparation are the 0.8 mass parts live lactic acid bacteria preparation of 1 billion / gram, which forms a mixture, and then the plastic bucket is placed in a cool place And seal the mouth of the plastic barrel with a rubber band to make the mixture in ...

Embodiment approach 2

[0050] This embodiment provides a method for recycling and processing all straw waste in the vegetable production process, which includes the following steps:

[0051] S1 collects the waste produced by pruning fresh vegetable stalks each time and cuts each section to 2 cm to obtain waste A;

[0052] S2 the waste A of 70 mass parts, the sucrose of 210 mass parts, the water of 720 mass parts all join in the plastic barrel of 1000L and mix evenly, then add the effective number of viable bacteria in the live bacteria preparation in the plastic barrel to be 10 0.5 mass parts of live saccharomyces preparations of 100 million / gram and 0.5 mass parts of live lactic acid bacteria preparations in which the number of effective viable bacteria in the live bacteria preparations is 1 billion / gram forms a mixture, and then the plastic bucket is placed in Place in a cool place and seal the mouth of the plastic barrel tightly with a rubber band to seal the mixture in the plastic barrel for air...

Embodiment approach 3

[0057] This embodiment provides a method for recycling and processing all straw waste in the vegetable production process, which includes the following steps:

[0058] S1 collects the waste produced by thinning flowers and fruits of fresh vegetable stalks each time and cuts each section to 3 cm to obtain waste A;

[0059] S2 all joins the water of the waste material A of 75 mass parts, the molasses of 220 mass parts, 745 mass parts in the plastic tank of 1000L and mixes evenly, then adds the effective number of viable bacteria in the live bacteria preparation in the plastic tank to be 1 billion / gram of 1 mass part of live yeast preparation and the effective number of live bacteria in the live bacterium preparation are 1 billion / gram of 1 mass part of lactic acid bacteria live preparation, which forms a mixture, and then the plastic barrel is placed Put it in a cool place and seal the mouth of the plastic barrel tightly with a rubber band to make the mixture in the plastic barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com