Method for preparing theaflavin by recycling polyphenol oxidase

A technology of polyphenol oxidase and theaflavins, which is applied in the biological field, can solve the problems of restricting the industrialization of theaflavins, poor thermal stability of theaflavins, and low extraction rate of theaflavins, etc., so as to facilitate continuous production and reliable Technical support, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

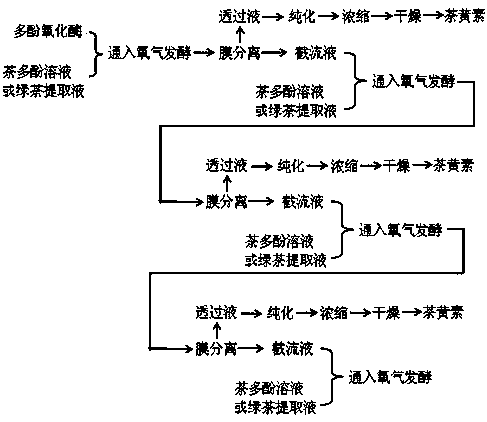

[0036]A method for preparing theaflavins by recycling polyphenol oxidase is characterized in that it comprises the following steps:

[0037] 1. Preparation of polyphenol oxidase solution:

[0038] 11) Crush fresh tea leaves into mud, add three times the mass of phosphate buffer solution with a pH value of 3.5, and mix evenly to obtain a mixture;

[0039] 12) According to the mass ratio of fresh tea leaves: cross-linked polyvinylpyrrolidone (PVPP) = 1000: 0.02, add cross-linked polyvinylpyrrolidone to the mixture in step 11), mix and emulsify for 5 minutes, filter, and polyphenol oxidase solution ;

[0040] Two, the preparation of liquid tea:

[0041] The tea leaves are crushed to pass through a 20-mesh sieve, and pure water is added according to the mass ratio of material to liquid of 1:10, and extracted for 90 minutes at a temperature of 70°C, the temperature of the extract is cooled to 25°C, and the extract is subjected to a clarification membrane with a molecular weight o...

Embodiment 2

[0057] A method for preparing theaflavins by recycling polyphenol oxidase is characterized in that it comprises the following steps:

[0058] 1. Preparation of polyphenol oxidase solution:

[0059] 11) Crush apples and bananas with a mass ratio of 1:1 into a puree, add phosphate buffer solution with a pH value of 6.5 that is 5 times the mass, and mix well to obtain a mixture;

[0060] 12) According to the mass ratio of apple and banana puree: cross-linked polyvinylpyrrolidone (PVPP) = 1000: 0.2, add cross-linked polyvinylpyrrolidone to the mixture in step 1), mix and emulsify for 20 min, filter, polyphenol oxidase liquid;

[0061] Two, the preparation of liquid tea:

[0062] The tea leaves are crushed to pass through a 50-mesh sieve, and pure water is added according to the mass ratio of material to liquid of 1:20, and extracted at 95°C for 30 minutes, the temperature of the extract is cooled to 45°C, and the extract is subjected to a clarification membrane with a molecular ...

Embodiment 3

[0081] A method for preparing theaflavins by recycling polyphenol oxidase is characterized in that it comprises the following steps:

[0082] 1. Preparation of polyphenol oxidase solution:

[0083] 11) Crush the eggplant, lotus root and carrot with a mass ratio of 1:2:1 into a puree, add 4 times the mass of phosphate buffer solution with a pH value of 5.5, and mix evenly to obtain a mixture;

[0084] 12) According to the mass ratio of eggplant, lotus root and carrot puree: cross-linked polyvinylpyrrolidone (PVPP) = 1000: 0.1, add cross-linked polyvinylpyrrolidone to the mixture in step 1), mix and emulsify for 10 minutes, filter, and polyphenols Oxidase solution;

[0085] Three, the preparation of theaflavin:

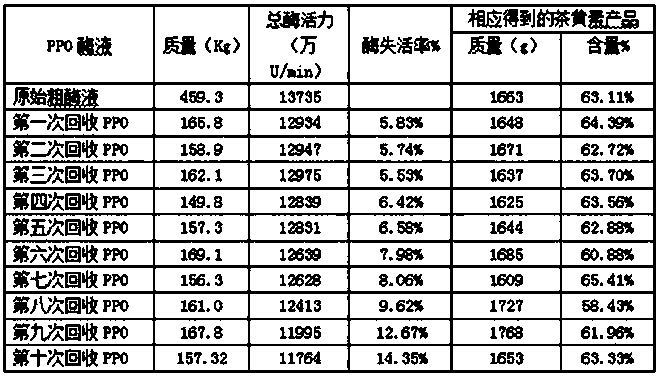

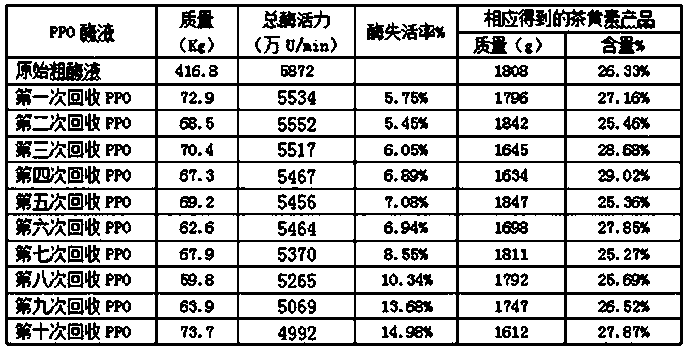

[0086] 21) Add polyphenol oxidase liquid to the fermentation broth until the mass concentration of eggplant, lotus root and carrot puree is 30%, then add commercially available tea polyphenols until the mass concentration of tea polyphenols in the fermentation broth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com