High electromechanical coupling coefficient acoustic surface wave device based on double-layer electrode and preparation method thereof

A surface acoustic wave device, aluminum electrode technology, applied in electrical components, coatings, metal material coating processes, etc., can solve problems such as low electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

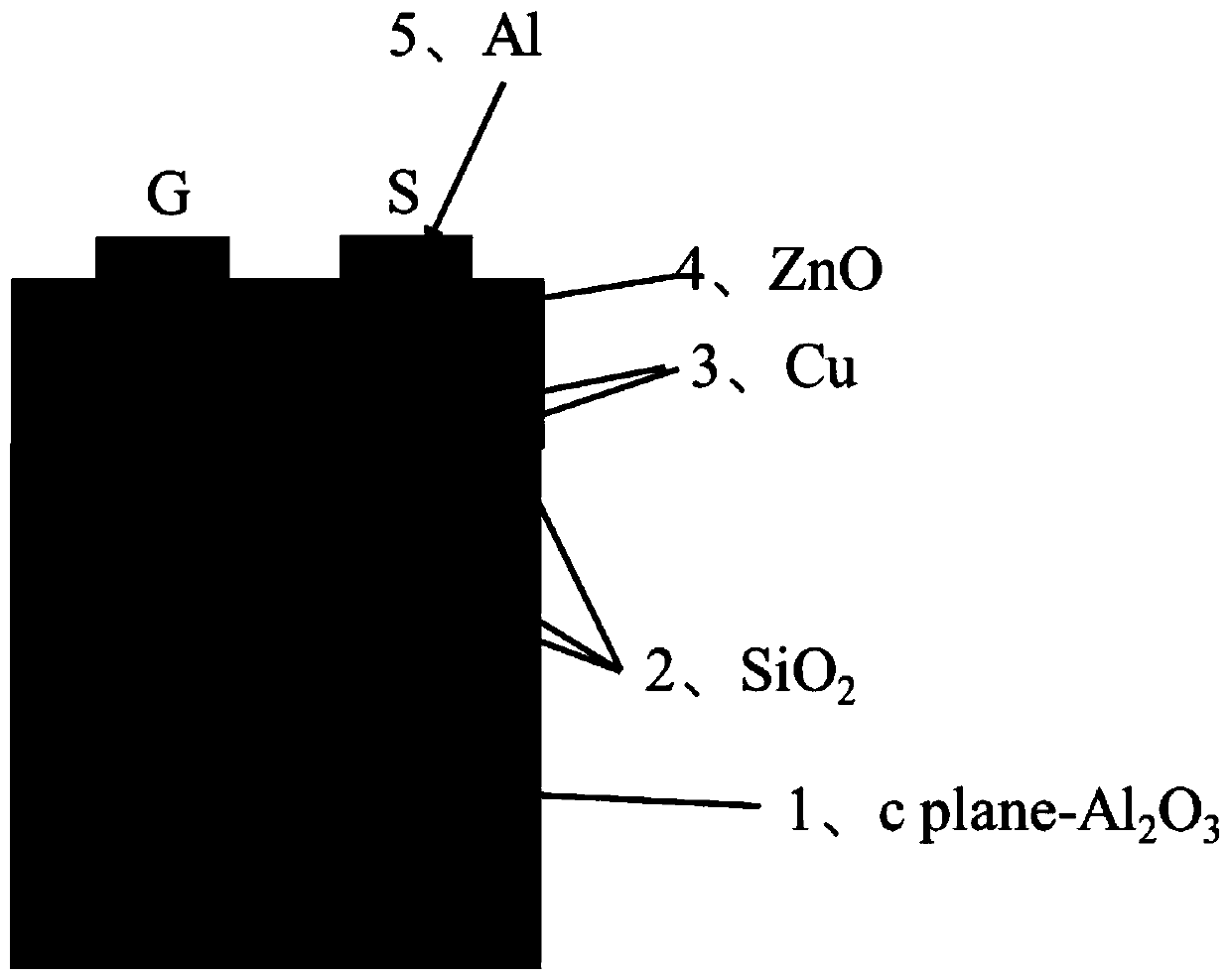

[0050] 1) A c-plane sapphire substrate with a pattern of interdigitated electrodes with a period of 2 microns is prepared by photolithography. After priming, the substrate is placed in an electron beam coater. Start the vacuum system to evacuate to 9×10 -6 Pa; adjust the power of the electron gun to 20%, and clean the target (purity is 99.999%) for 5 minutes.

[0051] 2) After the power reading is stable, open the target baffle, and the evaporation speed of the Cu electrode material is Deposit 75nm.

[0052] 3) After the evaporation is completed, turn off the power. Fill nitrogen into the vacuum chamber of the electron beam evaporation coating machine until the pressure in the vacuum chamber is atmospheric pressure, open the cavity and take out the sapphire substrate with the copper electrode deposited.

[0053] 4) Put the stripped substrate into the magnetron sputtering chamber to grow a silicon dioxide film, select the radio frequency sputtering mode, set the power to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com