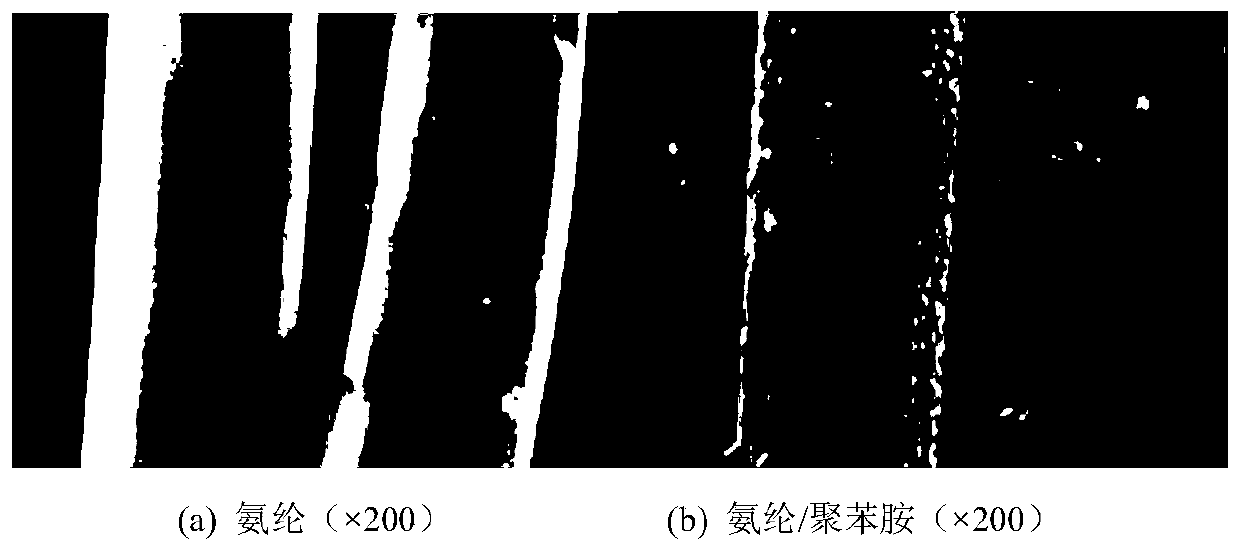

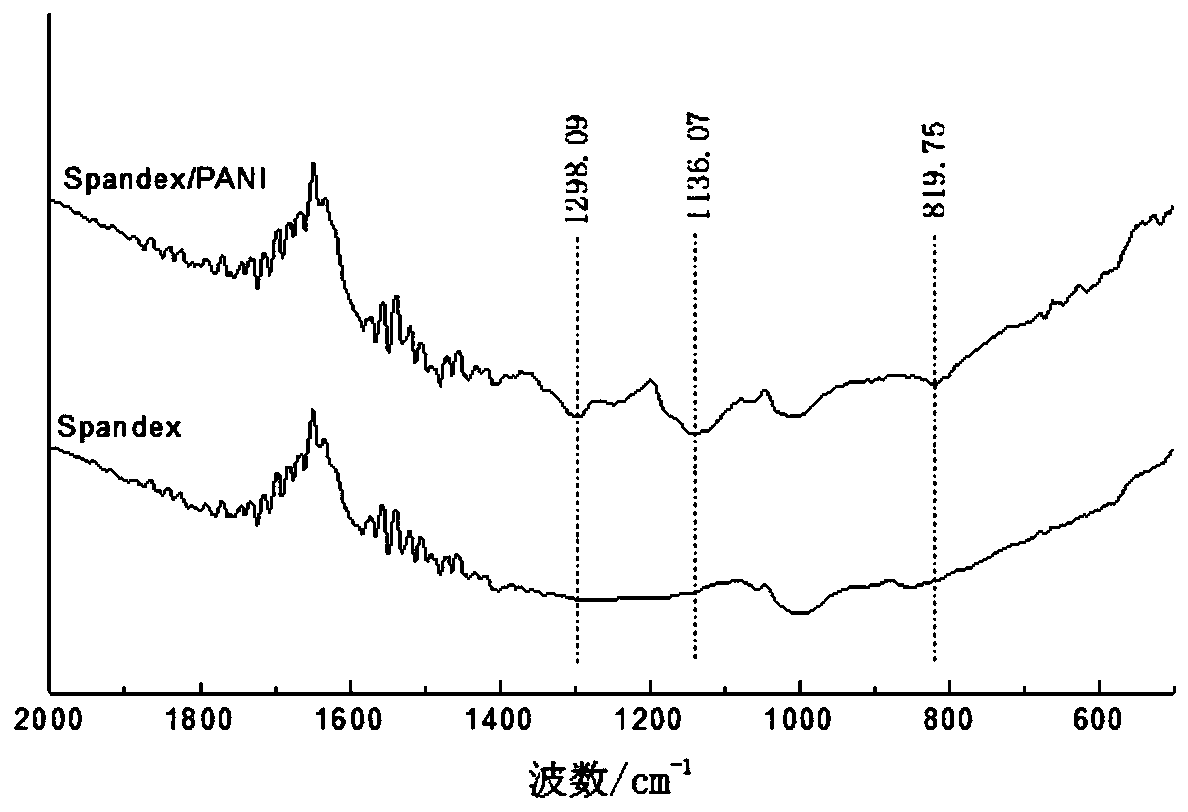

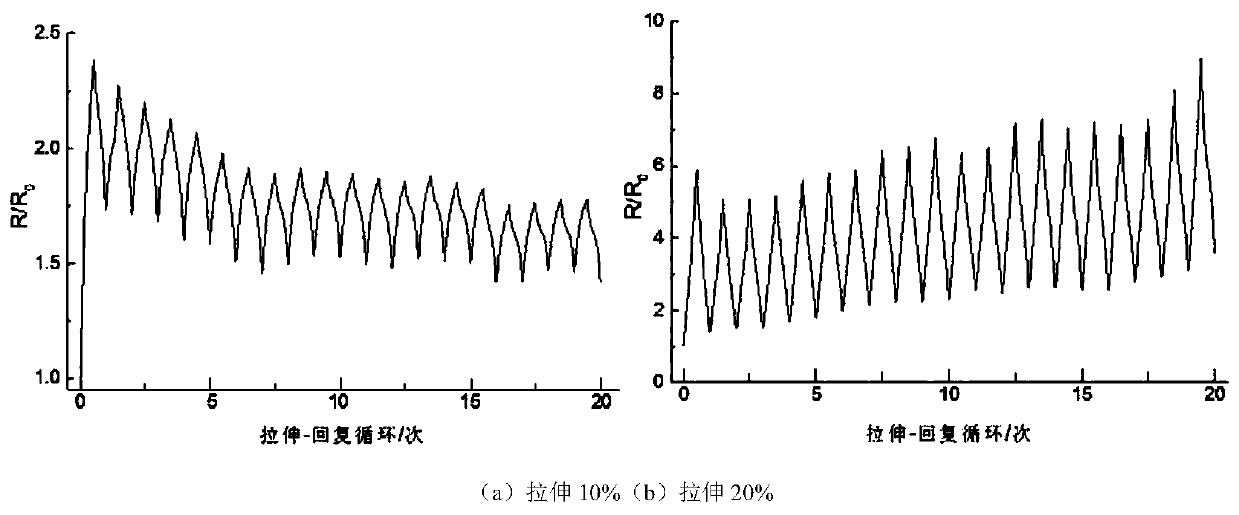

Preparation method of flexible wearable conductive spandex/polyurethane composite material

A composite material, polyurethane technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, fiber type, etc., can solve the problems of cumbersome fiber materials, achieve easy cracking, good strain sensing repeatability, and reduce process difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh the spandex fiber, put it in the aniline monomer, take it out after soaking for 60s, and then squeeze it evenly, control the mass ratio of the spandex fiber to the aniline monomer to be 1:1, put the squeezed spandex fiber in a beaker In 2h, the spandex fiber can fully absorb the aniline monomer. After 2 hours, weigh the mass of the spandex fiber that has absorbed the aniline monomer, and subtract the original mass of the spandex fiber to obtain the mass of the adsorbed aniline.

[0029] The reaction solution is prepared by using ammonium persulfate as the oxidizing agent and hydrochloric acid as the doping acid. The concentration of ammonium persulfate in the reaction solution is 30g / L, the concentration of hydrochloric acid is 1.0mol / L, and the mass volume ratio of An to the reaction solution is 1g: 100ml. Put the spandex fiber into the reaction liquid to seal the beaker, put the beaker into an air bath constant temperature oscillator at 24°C for uniform oscilla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com