Lithium-phosphorus-oxygen-nitrogen modified silicon-carbon composite material and preparation method thereof

A silicon-carbon composite material, lithium phosphorus oxynitride technology, applied in the field of materials, can solve the problems of low initial charge and discharge efficiency, poor cycle life, etc., and achieve the effects of good electronic conductive network, improved electrical conductivity, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

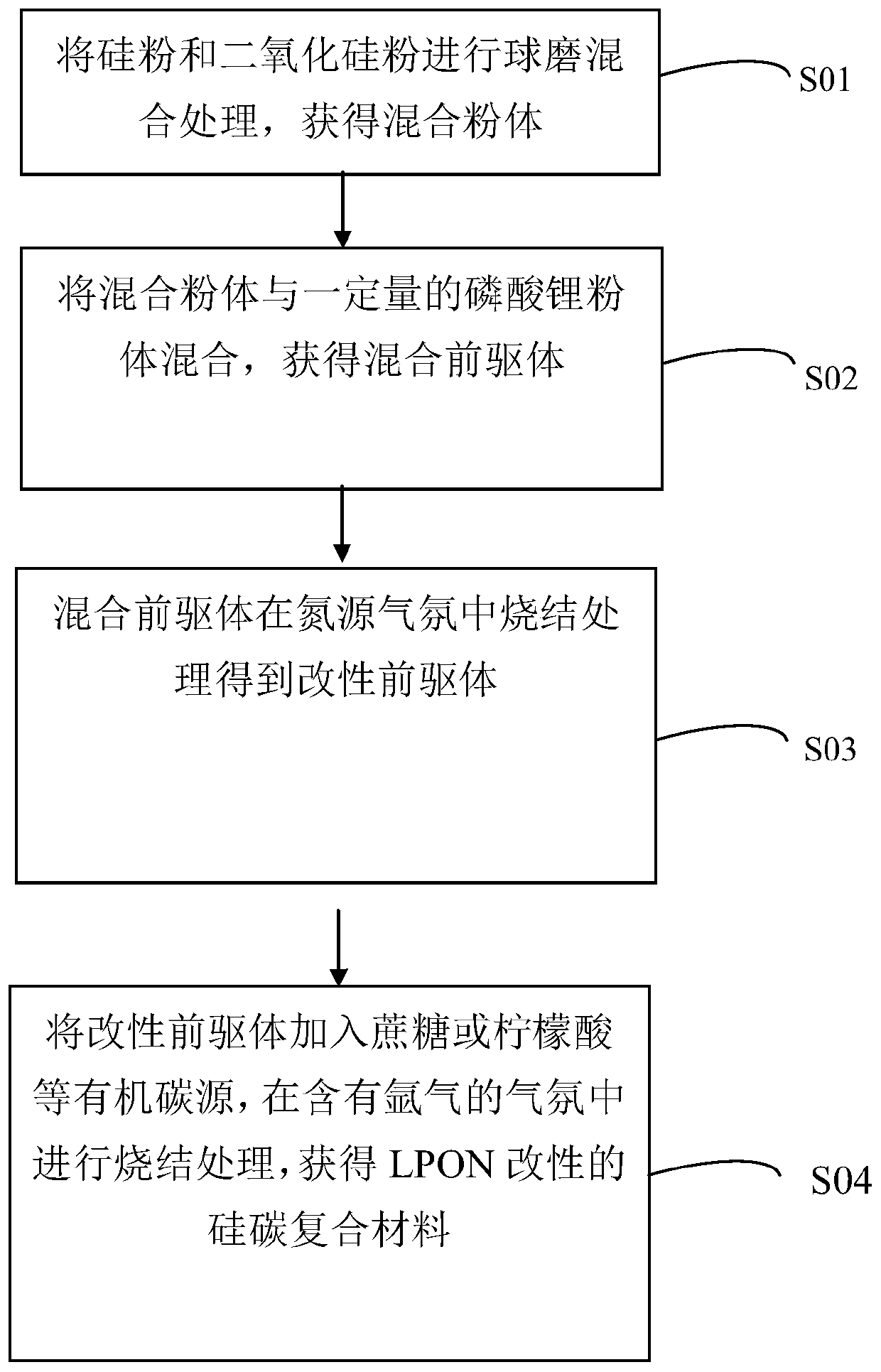

[0034] Such as figure 1 As shown, a method for preparing a silicon-carbon composite material includes the following steps:

[0035] In step S01, firstly, the silicon powder and the silicon oxide powder are mixed by high-energy ball milling to obtain a mixed powder SiO x .

[0036] Step S02, the mixed powder SiO x After ball milling and mixing with a certain amount of lithium phosphate powder, a mixed precursor is obtained.

[0037] Step S03, sintering the mixed precursor in a nitrogen source atmosphere to obtain a modified precursor.

[0038] In step S04, an organic carbon source such as sucrose or citric acid is added to the modified precursor, and then sintering is performed in an argon-containing atmosphere to obtain an LPON modified silicon-carbon composite material.

[0039] Wherein, in step S01, the silicon powder and the silicon oxide powder are subjected to ball milling and mixing, on the one hand, the components are fully mixed, and on the other hand, the particles of each comp...

Embodiment 1

[0052] This embodiment provides a LPON modified silicon carbon composite material, which is prepared by the following steps:

[0053] S11: Mix and grind nanometer silicon powder and submicron silicon oxide powder according to the molar ratio of 1:1, and put them in a ball mill for high-energy ball milling after uniform grinding. The milling speed is set to 300r / min, and the milling conditions are Set to forward rotation for 1h, reverse rotation for 1h, ball milling time 8 hours, after ball milling, after grinding, pass through a 100-150 mesh screen to collect materials, and obtain mixed powder SiO x .

[0054] S12: Then the powder SiO will be mixed x It is ball-milled and mixed with a certain amount of lithium phosphate powder, specifically according to the mass ratio of 6:4. The speed of the ball milling is set to 300r / min, the conditions of the ball milling are set to forward rotation for 1h, reverse rotation for 1h, and the milling time is 8 hours. After the milling, the materia...

Embodiment 2

[0058] This embodiment provides a LPON modified silicon carbon composite material, which is prepared by the following steps:

[0059] S11: Mix and grind nanometer silicon powder and submicron silicon oxide powder according to the molar ratio of 1:1, and put them into a ball mill for high-energy ball milling. The speed of the ball milling is set to 300 r / min. The conditions are set to forward rotation for 1 hour, reverse rotation for 1 hour, and the ball milling time is 8 hours. After ball milling, the material is collected through a 100-150 mesh screen to obtain a mixed powder SiO x .

[0060] S12: Then the powder SiO will be mixed x It is ball-milled and mixed with a certain amount of lithium phosphate powder, specifically according to the mass ratio of 5:5. The speed of the ball milling is set to 300r / min, the conditions of the ball milling are set to forward rotation for 1h, reverse rotation for 1h, and the milling time is 8 hours. After the milling, the materials are collected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com