Adenine-reinforced degradable soft tissue adhesive as well as preparation method and use method thereof

A technology of adenine and soft tissue, applied in the field of adenine-enhanced degradable soft tissue adhesives, which can solve the problems of low adhesion strength and achieve high glass transition temperature, high cohesive strength, and excellent degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The specific preparation process includes the following steps:

[0048] Step 1. PPF and PPF-DA are accurately weighed with a double bond ratio of 1:2 and placed in a round bottom flask containing 20mL-25mL dichloromethane.

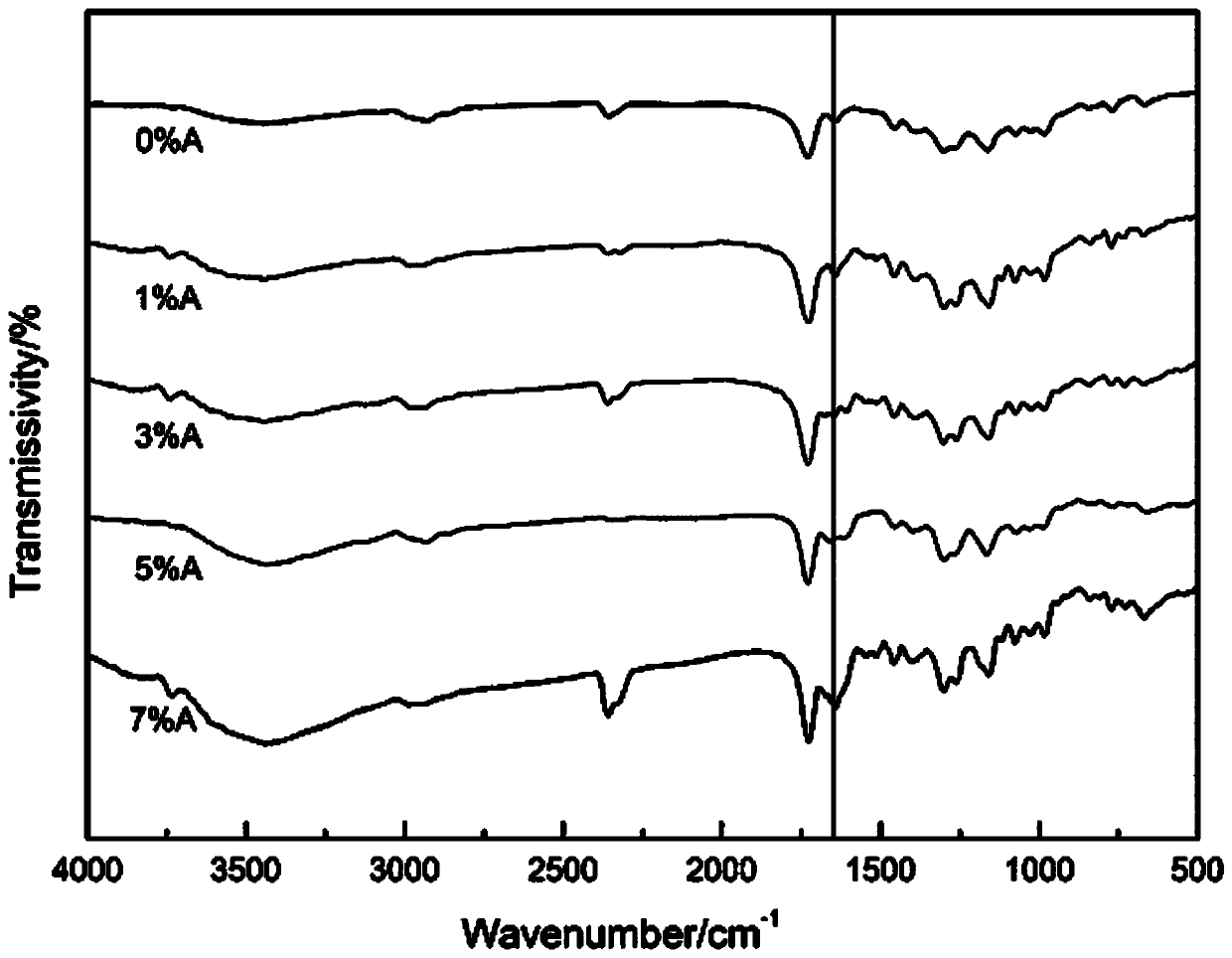

[0049] Step 2. Add adenine whose mass proportion is 1%-7% of the total mass of PPF, PPF-DA and adenine into the mixed system obtained in step 1, and stir for 0.5h with a magnetic stirrer to completely dissolve PPF and PPF-DA , Adenine is diffusely distributed, and mixture A is obtained.

[0050] Step 3. Rotary evaporation to remove the dichloromethane solvent in the mixture A under vacuum conditions. Rotary evaporation time is 0.67h-0.75h, temperature is 30℃-35℃, vacuum degree is not higher than 0.09MPa, and mixture B is obtained. During rotary evaporation, the temperature is gradually increased from 30℃ to 35℃.

[0051] Step 4, adding a photoinitiator BAPO solution with a mass proportion of 1.5% of the total mass of the mixture B to the mixture B. Under ...

Embodiment 1

[0058] The double bond ratio of PPF and PPF-DA is 1:2, mass ratio is 1:2.08, 0.48g PPF is accurately weighed, and 1g PPF-DA is placed in a round bottom flask containing 20 mL of dichloromethane. Use an analytical balance to weigh 0.0149g of adenine and place it in the above-mentioned PPF and PPF-DA mixed system (the mass of adenine in this example is 1% of the total mass of PPF, PPF-DA and adenine), and place the round bottom flask In a magnetic stirrer, stir at 400r / min for 0.5h to completely dissolve PPF and PPF-DA, and adenine is dispersed in the mixed solution. Under the vacuum condition not higher than 0.09MPa, set the temperature of the water bath of the rotary evaporator to 30°C, keep it for 13 minutes, raise it to 33°C, keep it for 13 minutes, and finally raise it to 35°C, keep it for 14 minutes, and rotate it for a total of The dichloromethane solvent was removed for 0.67h. Using a pipette, pipette 224 μL of the 0.1g / mL photoinitiator BAPO solution into the above roun...

Embodiment 2

[0060] The double bond ratio of PPF and PPF-DA is 1:2, mass ratio is 1:2.08, 0.48g PPF is accurately weighed, and 1g PPF-DA is placed in a round bottom flask containing 20 mL of dichloromethane. Use an analytical balance to weigh 0.0458g of adenine and place it in the above-mentioned PPF and PPF-DA mixed system (the mass of adenine in this example is 3% of the total mass of PPF, PPF-DA and adenine), and place the round bottom flask In a magnetic stirrer, stir at 400r / min for 0.5h to completely dissolve PPF and PPF-DA, and adenine is dispersed in the mixed solution. Under the vacuum condition not higher than 0.09MPa, set the temperature of the water bath of the rotary evaporator to 30°C, keep it for 13 minutes, raise it to 33°C, keep it for 13 minutes, and finally raise it to 35°C, keep it for 14 minutes, and rotate it for a total of The dichloromethane solvent was removed for 0.67h. Using a pipette, pipette 229 μL of the 0.1 g / mL photoinitiator BAPO solution into the above rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com