Recombinant escherichia coli for producing 5-methylpyrazine-2-carboxylic acid

A technology for recombining Escherichia coli and methylpyrazine, applied in the field of genetic engineering, can solve the problems of unstable industrial production of recombinant plasmids, short transformation time, environmental pollution, etc., and achieve good industrialization prospects, shorten the cycle, and high transformation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1. Construction of recombinant Escherichia coli producing 5-methylpyrazine-2-carboxylic acid

[0049] According to the NCBI published E. coli Escherichia coli The genome sequence of BL21(DE3) designed the amplification primers for the upstream and downstream homology arms of the flhD site, and the upstream and downstream primers for the left arm were:

[0050] up-flhD-F:5'-CGTCTTTTTTACTGCCCGGGATG-3'

[0051] up-flhD-R:5'-ATCTTAAGGGTCTGATCACATTATACGAGCCGATGATTAATTGTCAAAGCAAATTCATACCGGCATCATGC-3'

[0052] The upstream and downstream primers of the right arm are:

[0053] B-down-flhD-F:5'-CGGTACTCCGGATTGGTTGAGTGTTTCAGCAACTCGGAGGTATGC-3'

[0054] down-flhD-R:5'-CTGATTCTCCGCATTGAACAAGTGG-3'

[0055] Escherichia coli Escherichia coli The left and right arms contained in the amplified integration frame in the BL21(DE3) genome.

[0056] According to the sequence of xylene monooxygenase gene Gene ID: 1218754 and Gene ID: 1218743, benzyl alcohol dehydrogenase gene...

Embodiment 2

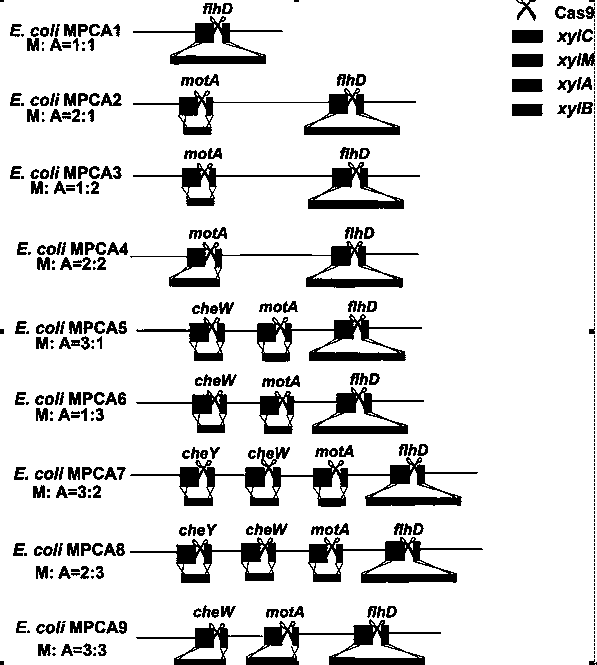

[0061] Example 2. Construction of different xylene monooxygenase double subunit genes wxya with xylA 5-Methylpyrazine-2-carboxylic acid-producing recombinant Escherichia coli with copy number ratio

[0062] to build E. coli MPCA2 (xylM:xylA=2:1), E. coli MPCA3 (xylM:xylA=1:2) and E. coli MPCA4 (xylM:xylA=2:2) according to NCBI published Escherichia coli Escherichia coli The genome sequence of BL21(DE3) designed the upstream and downstream homologous arm amplification primers of the motA site. The left arm primers are all consistent, and the left arm upstream and downstream primers are respectively:

[0063] up-motA-F:5'-CGATGTTCGGCTGCTTATTCACTTC-3'

[0064] up-motA-R:5'-ATCTTAAGGGTCTGATCACATTATACGAGCCGATGATTAATTGTCAAACTTTCCTCGGCATTTTATTGGCTTAC-3'

[0065] E. coli The right arm primer of MPCA2 (xylM:xylA=2:1) is:

[0066] M-down-motA-F: 5’-GGTGGCTAGCATTTGAGATTTCGCCATCAACCGAT-3’

[0067] down-motA-R:5'-TTCCAGCTGCAACTGCTGC-3'

[0068] E. coli MPCA3 (xyl...

Embodiment 3

[0122] Example 3. Production of 5-methylpyrazine-2-carboxylic acid by fermenting recombinant Escherichia coli

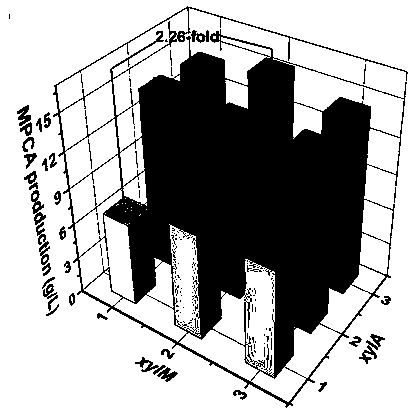

[0123] The obtained nine 5-methylpyrazine-2 carboxylic acid-producing recombinant Escherichia coli MPCA1-9 were cultured with seed medium at 37°C and 220rpm for 12h, and then transferred to fermentation culture with a 1% inoculation amount based on 37 ℃, 220rpm fermentation for 12h, centrifuged to collect the cells, and then adding 12g / L substrate DMP in pH 8 buffer for catalysis for 36h. The formula of the buffer solution is: 1.6 g / L sodium dihydrogen phosphate dihydrate, 67.8 g / L disodium hydrogen phosphate dodecahydrate. The 9 strains of above-mentioned construction are carried out fermentation output comparison, when catalysis ends, use the content of 5-methylpyrazine-2-carboxylic acid in the fermented broth to measure by high performance liquid chromatography, the result is as follows figure 2 shown. in E. coli MPCA8 (xylM:xylA=2:3) had the highest yield, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com