Process and system for producing fused magnesite by taking magnesium hydroxide as raw material

A technology of magnesium hydroxide and fused magnesia, which is applied in magnesium oxide, chemical industry, sustainable manufacturing/processing, etc. Small pollution, short process and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

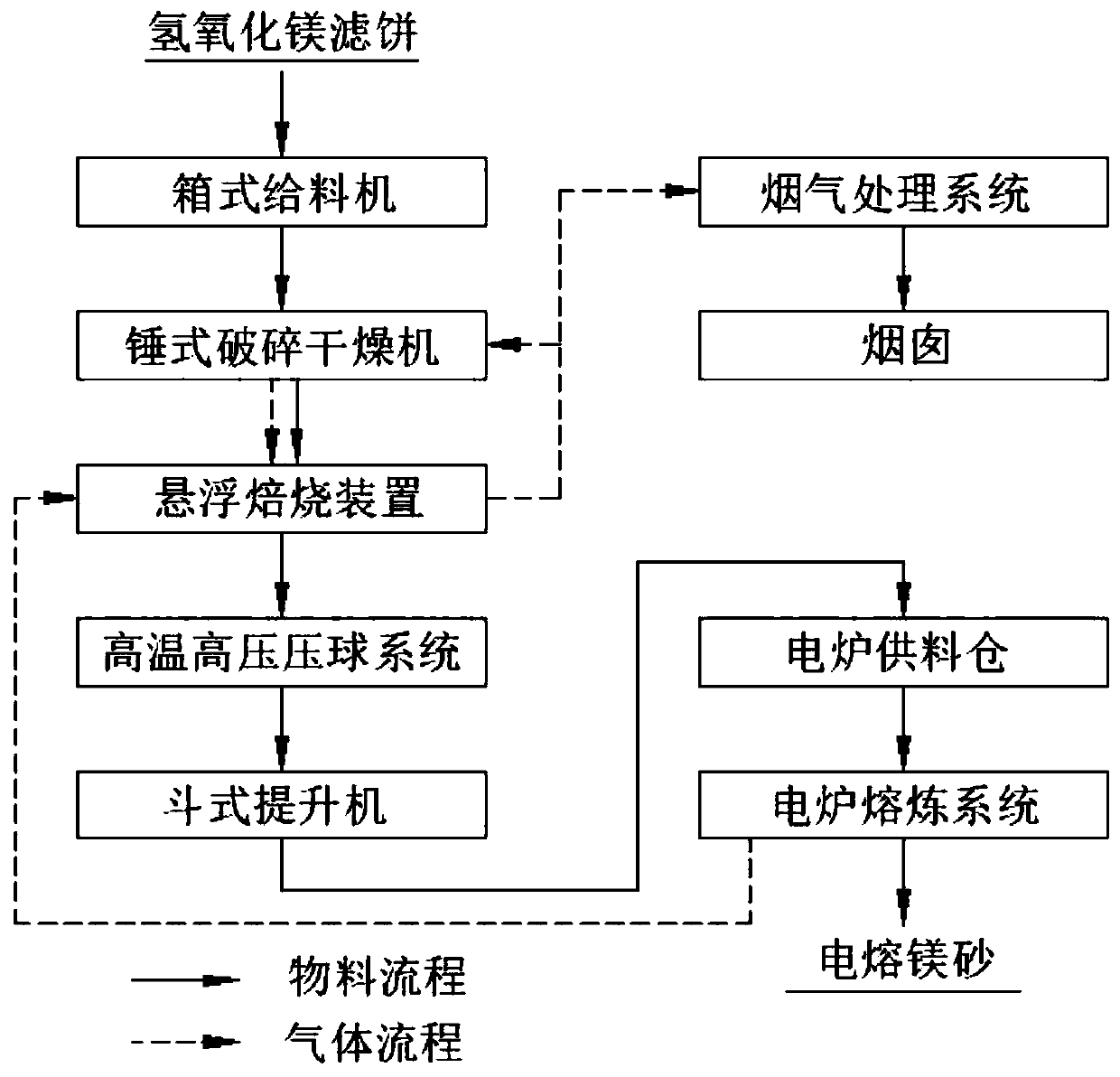

[0031] Such as figure 1 , figure 2 As shown, a kind of process that uses magnesium hydroxide as raw material to produce fused magnesia according to the present invention, the magnesium hydroxide filter cake that seawater or brine is made is sent into hammer crusher dryer through box feeder 2 Carry out crushing and drying in 3, and the magnesium hydroxide powder after crushing and drying enters the suspension roasting device 4 together with the drying wind for preheating and roasting, and the obtained magnesium oxide is sent to the high-temperature and high-pressure ball pressing system 5 for cyclic hot pressing. The obtained magnesia balls are stored in the electric furnace feeding bin 7 through the bucket elevator 6, and then sent to the electric furnace smelting system 8 for smelting to obtain fused magnesia products.

[0032] The hammer drye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com