Energy-releasing composite preparation and preparation method thereof

A compound preparation and energy release technology, which is applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve life-threatening, dangerous, dangerous and other problems, and achieve the effect of reducing water injection pressure and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

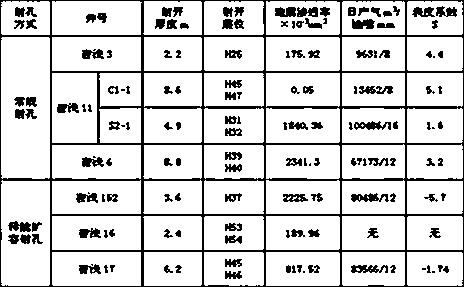

Examples

Embodiment 1

[0020] A kind of energy-releasing compound preparation of the present invention, it is by weight ratio, by 41 parts of binders, 40 parts of combustion agents, 5 parts of functional additives, 8 parts of accelerators, 1 part of curing agent and 5 parts of crack propping agents mixed.

[0021] The adhesive is epoxy resin.

[0022] The combustion agent is tungsten powder.

[0023] The functional additive is titanium powder.

[0024] Described accelerator is dimethylethanolamine.

[0025] The curing agent is 650 low molecular weight polyamide.

[0026] The fracture proppant is gravel.

[0027] Among them, the epoxy resin is used to provide bonding metal particles; the function of the combustion agent is to generate kinetic energy through the high-speed collision of high-density metal mixed particles in the perforation tunnel to stimulate the jet channel, and the damage and compaction will cause pollution; the function of the functional additive is to expand The pore volume in...

Embodiment 2

[0029] An energy-releasing composite preparation of the present invention, which is proportioned by weight, consists of 53 parts of binder, 60 parts of combustion agent, 15 parts of functional additive, 10 parts of accelerator, 3 parts of curing agent and 7 parts of crack proppant mixed.

[0030] The adhesive is a mixture of phenolic resin and silicone rubber in a mass ratio of 1:2.

[0031] The combustion agent is a mixture of tungsten powder and copper powder with a mass ratio of 1:1.

[0032] The functional additive is a mixture of titanium powder, bismuth powder and copper oxide in a mass ratio of 1:1:2.

[0033] The accelerator is 2,4,6-tris(dimethylaminomethyl)phenol.

[0034] The curing agent is m-phenylenediamine.

Embodiment 3

[0036] An energy-releasing composite preparation of the present invention, which is proportioned by weight, consists of 50 parts of binder, 50 parts of combustion agent, 10 parts of functional additive, 9 parts of accelerator, 2 parts of curing agent and 6 parts of crack proppant mixed.

[0037] The adhesive is silicone rubber.

[0038] The combustion agent is a mixture of nickel powder and zirconium powder with a mass ratio of 2:3.

[0039] The functional additive is a mixture of titanium powder and copper oxide in a mass ratio of 3:4.

[0040] The accelerator is a mixture of tetramethylethylenediamine and 1-dimethylamino-3-phenoxypropanol in a mass ratio of 4:3.

[0041] The curing agent is a mixture of 650 low molecular weight polyamide, fatty polyamine and m-xylylenediamine in a mass ratio of 4:1:1.

[0042] The alicyclic aromatic hydrocarbon polyamine is m-phenylenediamine or .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com