Heat conduction insulating adhesive tape and preparation method thereof

A technology of thermal insulation and thermal conductive adhesive, which is applied in the directions of adhesives, adhesive types, film/sheet adhesives, etc. Effects of stability and service life, short process flow, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

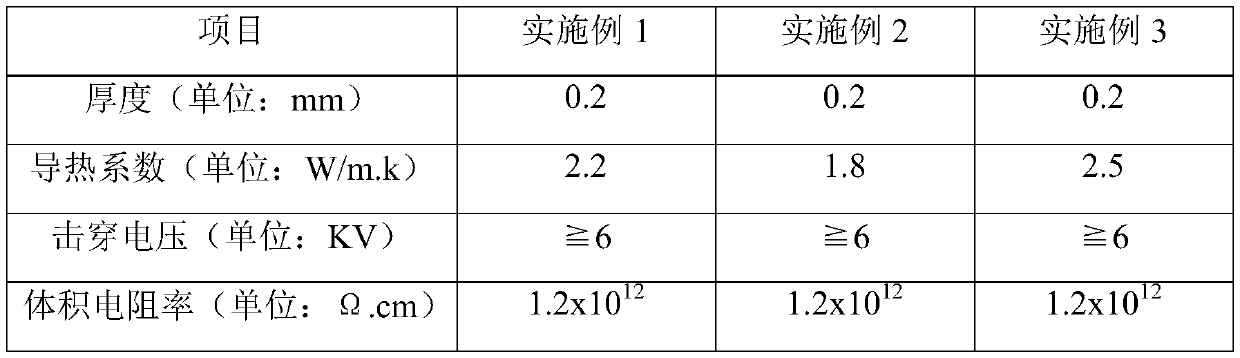

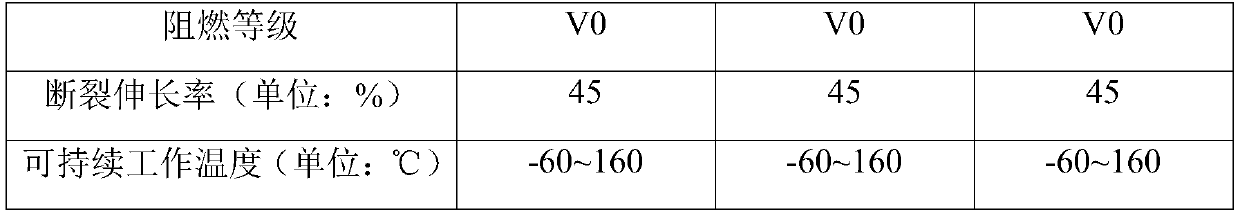

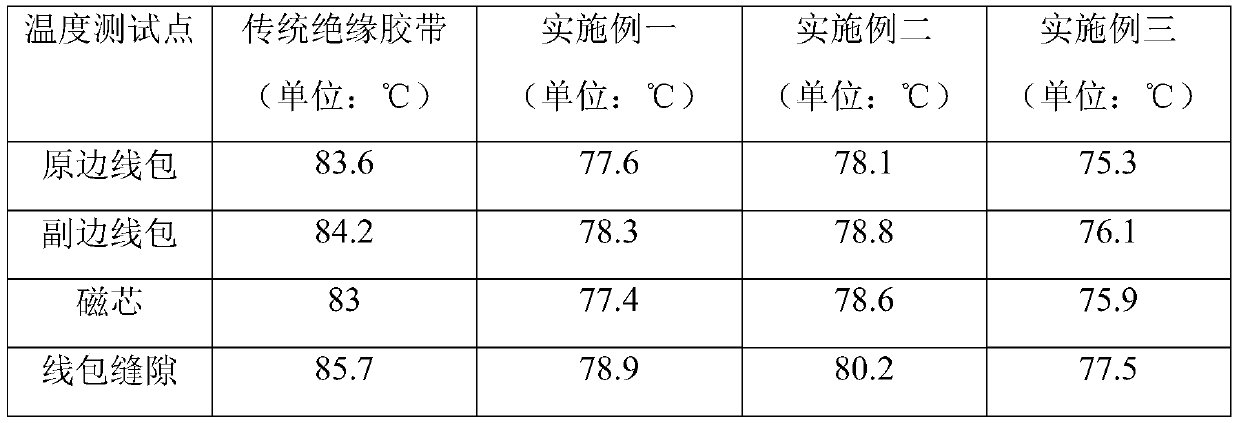

Embodiment 1

[0030] In this embodiment, the present invention provides a thermally conductive insulating adhesive tape, which includes a substrate layer, a thermally conductive adhesive layer, and a release film layer arranged in sequence from bottom to top. Wherein the substrate layer is a non-woven fabric substrate; the thermally conductive adhesive layer includes the following raw materials in parts by weight: 100 parts of adhesive, 125 parts of nano thermal conductive filler, 2 parts of heat stabilizer, 3 parts of antioxidant, plasticizer 5 parts of agent, 1.5 parts of coupling agent and 40 parts of solvent, wherein in the present embodiment, the adhesive is silicone adhesive, the nano thermal conductive filler is nano ceramic powder thermal conductive filler, and the plasticizer is phthalate Diisooctyl formate, the solvent used is xylene, and the coupling agent is a silane coupling agent.

Embodiment 2

[0032] In this embodiment, the present invention provides a thermally conductive insulating adhesive tape, which includes a substrate layer, a thermally conductive adhesive layer, and a release film layer arranged in sequence from bottom to top. Wherein the substrate layer is a non-woven substrate; the thermally conductive adhesive layer includes the following raw materials in parts by weight: 120 parts of adhesive, 140 parts of nano thermal conductive filler, 1.5 parts of thermal stabilizer, 2.5 parts of antioxidant, plasticizing 6 parts of agent, 2 parts of coupling agent and 45 parts of solvent, wherein in the present embodiment, the adhesive is acrylic adhesive, the nano thermally conductive filler is nano ceramic fiber thermally conductive filler, and the plasticizer is phthalic acid Dibutyl ester, the used solvent is butanone, and the coupling agent is a titanate coupling agent.

Embodiment 3

[0034] In this embodiment, the present invention provides a thermally conductive insulating adhesive tape, which includes a substrate layer, a thermally conductive adhesive layer, and a release film layer arranged in sequence from bottom to top. Wherein the substrate layer is a non-woven fabric substrate; the thermally conductive adhesive layer includes the following raw materials in parts by weight: 115 parts of adhesive, 150 parts of nano thermal conductive filler, 2.5 parts of thermal stabilizer, 3.5 parts of antioxidant, plasticizing 8 parts of agent, 2 parts of coupling agent and 45 parts of solvent, wherein in the present embodiment, the adhesive is polyurethane adhesive, the nano thermally conductive filler is nano ceramic whisker thermally conductive filler, and the plasticizer is phthalate Dimethyl formate, the solvent used is toluene, and the coupling agent is a titanate coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com