Foamed nickel for supporting metal nickel and vanadium trioxide composition and preparation method and application of foamed nickel

A vanadium trioxide and metal-loaded technology, applied in metal/metal oxide/metal hydroxide catalysts, vanadium oxide, chemical instruments and methods, etc., can solve the problems of high price, inability to promote, and low storage content. , to achieve the effect of easy application, favorable for large-scale industrial application, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

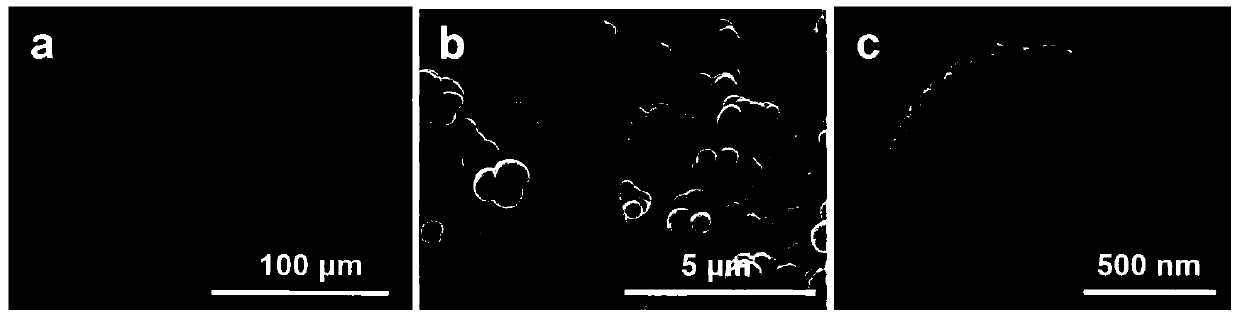

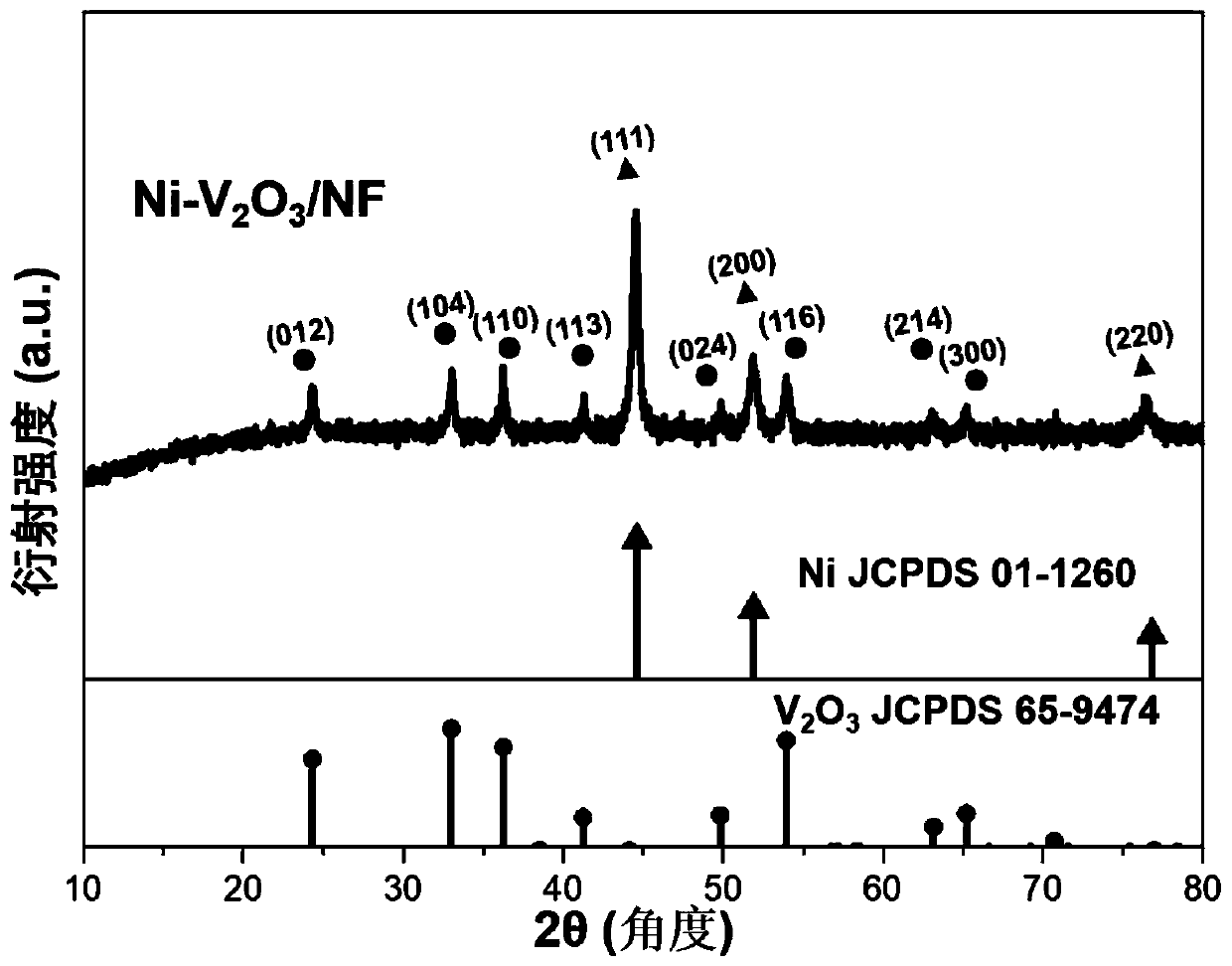

[0033] Step 1, preparation of nickel foam loaded with metal nickel and vanadium trioxide composite

[0034] 4mmol NiCl 2 6H 2 O, 4 mmol NH 4 VO 3 ,0.6g NH 4F and 1.2g of urea were added to 40mL of deionized water, stirred for 30 minutes to disperse evenly, and the obtained mixed solution was placed in a polytetrafluoroethylene-lined steel sleeve, and 5 pieces of nickel foam of 1 square centimeter were placed in it. React in an oven for 9 hours, and after naturally cooling to room temperature, take out the nickel foam, wash it with deionized water, and dry it in a vacuum oven at 60°C. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.02L min -1 , Argon gas flow rate is 0.08L min -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 50...

Embodiment 2

[0048] 2mmol NiCl 2 6H 2 O, 2 mmol NH 4 VO 3 ,0.3g NH 4 Add F and 0.6g urea to 40mL deionized water, stir for 30 minutes to disperse evenly, place the obtained mixed solution in a polytetrafluoroethylene-lined steel sleeve, put 5 pieces of nickel foam of 1 square centimeter, React in an oven for 9 hours, and after naturally cooling to room temperature, take out the nickel foam, wash it with deionized water, and dry it in a vacuum oven at 60°C. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.02L min -1 , Argon gas flow rate is 0.08L min -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 500°C at a constant temperature for 60 minutes; then cool down to room temperature naturally, take out the quartz ark, and obtain nickel foam load...

Embodiment 3

[0050] 6mmol NiCl 2 6H 2 O, 6 mmol NH 4 VO 3 ,0.9g NH 4 F and 1.8g of urea were added to 40mL of deionized water, stirred for 30 minutes to disperse evenly, and the obtained mixed solution was placed in a polytetrafluoroethylene-lined steel sleeve, and five pieces of nickel foam of 1 square centimeter were put in. React in an oven for 9 hours, and after naturally cooling to room temperature, take out the nickel foam, wash it with deionized water, and dry it in a vacuum oven at 60°C. The dried nickel foam is loaded into the quartz ark; the quartz ark is pushed into the central hot zone of the tube furnace, and the flange is sealed; the hydrogen and argon are measured by the rotameter (the hydrogen flow rate is 0.02L min -1 , Argon gas flow rate is 0.08L min -1 ) into the tube furnace after being fully mixed; at 5°C min -1 Raise the temperature of the tube furnace to 500°C at a constant temperature for 60 minutes; then cool down to room temperature naturally, take out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com