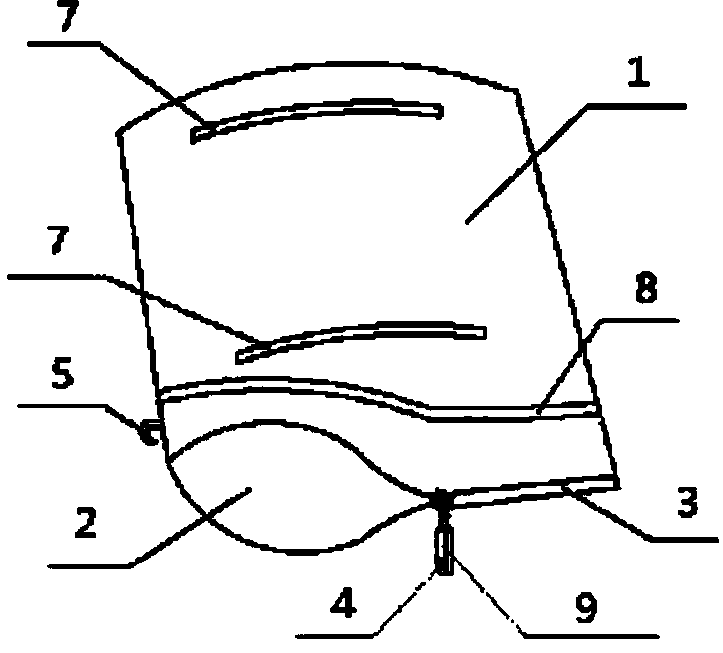

[0008] ①The flood control sandbag plays the role of flood control and

water retention is sand, and the sand is filled in a fine-mesh bag (commonly made of cloth fabrics such as canvas or cotton linen), and it is slightly improper in use or improper in daily storage (for example, there are mice) chewing, etc.) can easily lead to damage to the fabric of the bag’s surface and sand leakage. Once the sand in the sandbag leaks excessively, it will easily cause the density and density of the sand to decrease, and eventually cause the

porosity between the sand to increase, unable to

resist the

impact of incoming water and effectively intercept the sand. water;

[0009] ②Sandbags are generally filled with high-density sand, and a bag of sandbags is also relatively large, resulting in a bag of sandbags of high quality (heavier in weight), which is not convenient for

manual handling (there are certain requirements for the

physical fitness and fitness of the moving personnel). Even if there are small sandbags with small volume and light weight, although the load on the handling personnel is reduced, if a temporary waterproof project of a certain scale (long length and high height) is to be built, the total amount of sandbags required is also relatively large, which directly increases The number of times the user carries sandbags back and forth indirectly increases the load of the personnel on the other hand;

[0010] ③

Flood control sandbags have the function of retaining water and intercepting water, but when building temporary

waterproofing works, the gaps between sandbags are easy to seep (that is, the weak points of water interception), so generally multiple rows of sandbags are used. Deal with

water seepage in the plugging gap to ensure the water interception effect. At the same time, if the incoming water is huge, the flood control sandbags should be stacked according to the maximum interception height of the incoming water, and the sandbags are arranged in a trapezoidal shape when stacked, and the

water pressure of the uppermost layer is the smallest, so the number of stacked rows At least, the lowest layer has the highest

water pressure, so the number of stacked rows is the largest. Such a

waterproofing project will consume a lot of sandbags, manpower and

material resources. If the number of stacked rows is not enough or the stacking height is not in place, it is easy to cause

water seepage between sandbags, and incoming water will not pass through the top sandbags. , even if the

water pressure is too large or the

impact load of incoming water is large, it may easily cause the sandbag flood control project to collapse and be destroyed, which will cause certain economic losses and safety risks

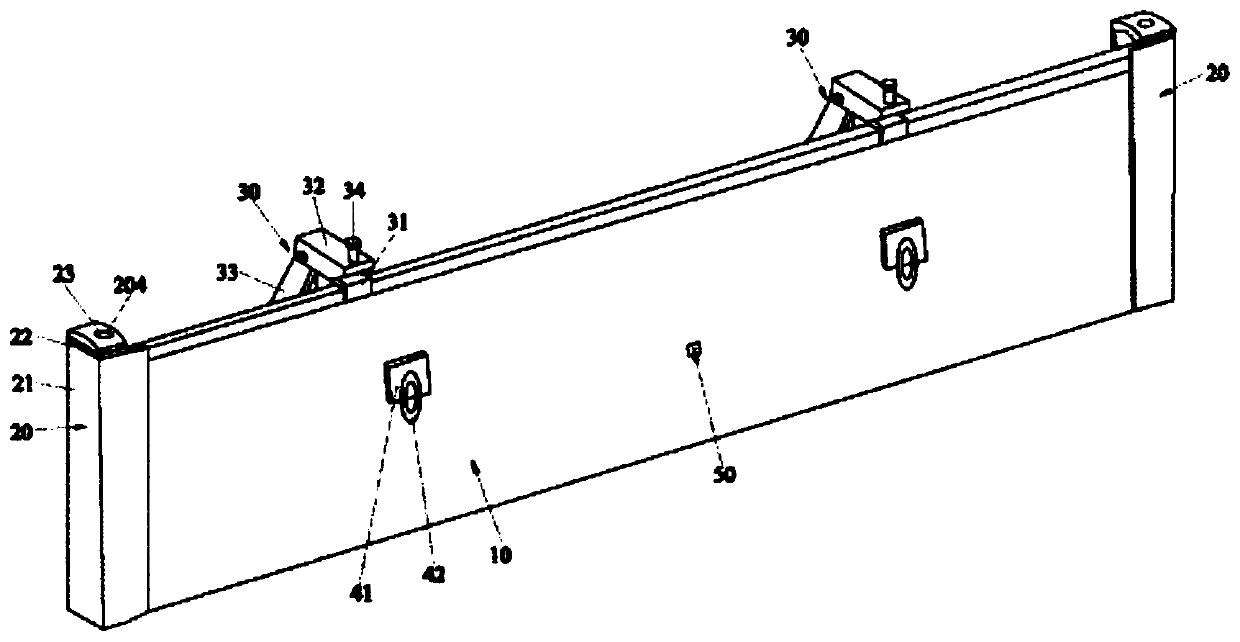

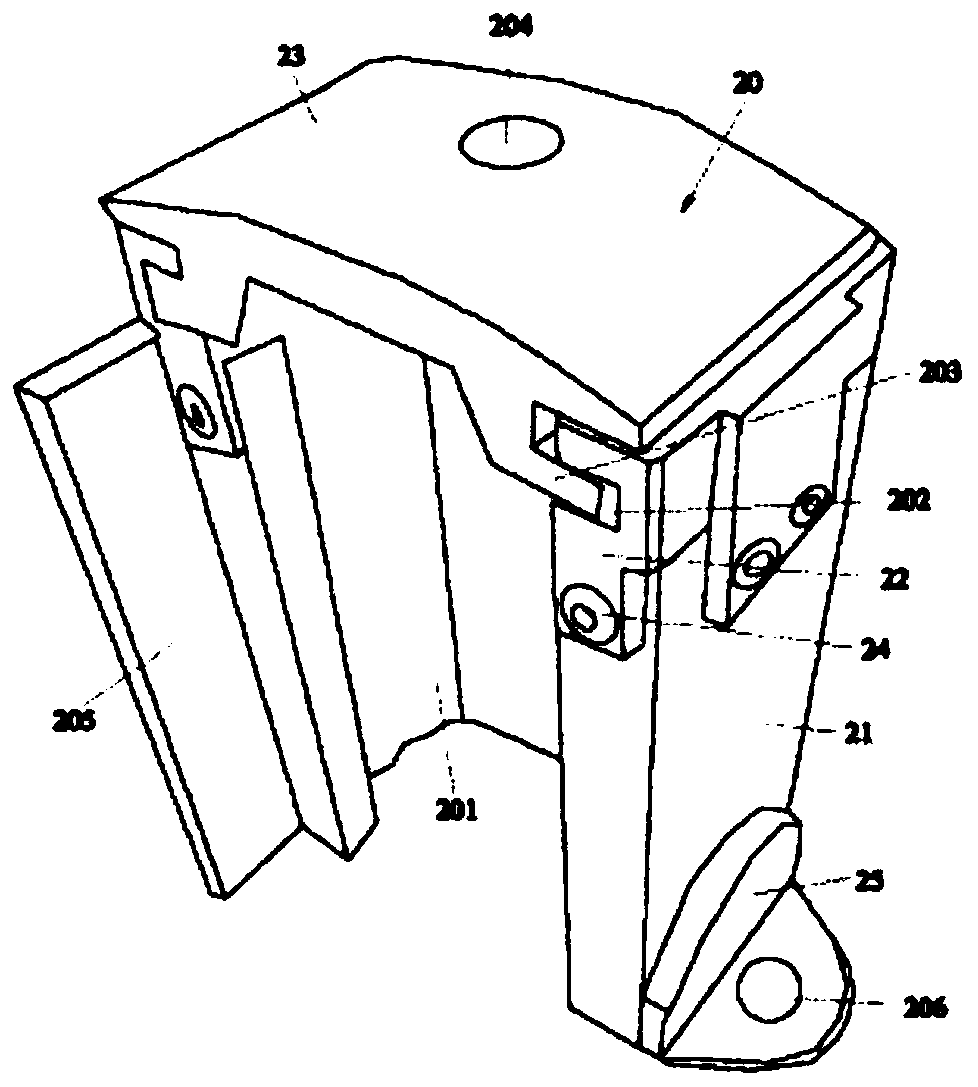

[0014] ① The actual maximum height of the flood control baffle is limited by the height of the fixed notch reserved in its positioning and fixing components. If the height of the fixed notch is high, several water baffles can be inserted vertically to raise its The highest water-retaining height, and vice versa, but the reserved height of the conventional fixed notch is generally low, so the maximum water-retaining height of the water-retaining plate is also low, and the water-retaining capacity is limited

[0015] However, if the reserved height of the fixed notch is high, it will cause two problems: one is that it is difficult to deal with the waterproof and anti-leakage of the gaps between several water retaining plates inserted vertically, and there is no better treatment method for the time being; Replace some small water baffles with a large large water baffle with a high height and insert them into the reserved high fixed slots, it will be more difficult to insert into the slots, and the water baffle itself is made of

metal, which may cause damage if the size is too large. The self-weight is too large, and manual operation is very inconvenient. It is also very inconvenient to manually take out the large water baffle after use. At the same time, the movable supports corresponding to the large water baffle may be specially customized, which consumes manpower,

material resources and financial resources.

[0016] Therefore, when the water retaining plate works with a limited and low water retaining height and water retaining capacity, if the incoming

water volume is huge or the

water level rises rapidly, once the water retaining capacity is exceeded, it is very easy for the incoming water to submerge the water retaining plate and submerge behind it. area, at this time, the water retaining function of the water retaining plate is completely invalid

[0017] ②The water baffle can only be used in the parts or areas where the positioning and fixing components have been installed in advance. The location and scope of use are limited by the installation position of the positioning and fixing components. Flood control cannot be implemented in other places where there is a need but no positioning and fixing components are installed. The water retaining board is used to block water, and the water retaining board is generally placed on an ideal level ground. If the ground is uneven, the water retaining board cannot be effectively placed and used, which will cause

water seepage from the ground depression, and the water retaining effect will be greatly reduced , it highlights that its use is limited, and it takes a certain amount of time to install the positioning and fixing components in advance, and the existing building structure must be modified. The preparation work is relatively large, and it consumes manpower,

material resources and time.

[0018] ③Because the

fender facilities are all assembled and spliced by

metal parts, each part of the

metal parts will inevitably suffer from wear, loss or

corrosion after long-term use.

Purchasing certain spare parts and consumable parts for emergency maintenance and use will consume manpower, material resources and financial resources, and the later stage will cost more and be less economical. Less), it makes its cost of use higher, highlighting its low

cost performance[0024] ① The water blocking capacity of the water retaining gate of the quick-installed water retaining gate is also similar to that of the flood control water retaining plate. It is easy to cause the depth of accumulated water around the

sluice plate to be too deep in a short period of time. When the depth of the accumulated water exceeds the upper surface of the

sluice plate, the accumulated water will submerge the

sluice plate and submerge the area behind it, and its function of retaining and intercepting water will be completely ineffective. At the same time, the difference from the flood control baffle is that the upper part of the baffle is provided with a lifting ring part and a supporting

concave surface, which will cause the lifting ring to be retracted to the designated position even if it is not activated (such as Figure 7 to Figure 11 As shown), the top of the lifting ring will also have exposed protrusions relative to the upper surface of the gate plate, so that even if multiple water retaining gates are inserted into the reserved slots of the positioning component, the upper and lower gates will not be able to move due to the exposed protrusions of the lifting rings. Effectively closes the joint, leaving a seam through which water seeps, and ultimately fails to achieve an increase in the height of the water-retaining

cut-off, thereby limiting its water-retaining and

cut-off capabilities

[0027]

However, whether it is the preparation of positioning or fixing components, it is determined that the location and scope of use of the sluice plate have certain limitations, and other places where there is a need but no positioning and fixing components are installed, the flood control sluice plate cannot be used to retain water , and the water retaining gate is generally placed on an ideal level ground for use. If the ground is uneven, the water retaining gate cannot be effectively placed and used, which will cause incoming water to seep from the ground depression, and the water retaining effect will be greatly reduced, which highlights its use. The limitations are relatively large, and it takes a certain amount of time to install the positioning and fixing components in advance, and the existing building structure must be modified. The preparation work is relatively large, and it consumes manpower, material resources and time

[0028] ③Because there are a lot of parts in the

sluice gate facilities, and most of them are metal parts, which are assembled and spliced by these parts, each part of the metal parts will inevitably have problems such as wear, loss or

corrosion after long-term use. Regularly send special personnel to carry out maintenance and repairs, and at the same time, it is necessary to purchase additional spare parts and consumable parts for emergency repairs and use, which consumes manpower, material and financial resources, and the subsequent expenses are relatively large, and the economy is poor. , if the

frequency of use of the

sluice gate facility is not high (the number of times of use is small), it will make its use cost higher, highlighting its low

cost performance[0035] ① The water-retaining capacity and height of the water-absorbing expansion bag flood control and water-retaining facilities are limited by the height of its own plate body. It is easy to accumulate water too deep in a short period of time. When the depth of accumulated water exceeds the height of the plate body (water retaining capacity), the accumulated water will overflow from the top surface of the plate body and then submerge the area behind. At this time, the water retaining facility It will completely fail, and the water retaining facility only supports horizontal splicing and lengthening, and cannot achieve vertical heightening, so its water retaining height and capacity are not as good as the aforementioned flood control sandbags, flood control water retaining boards and quick-installed water retaining gate facilities. And when the horizontal splicing is long, the waterproof and water-retaining parts and sealing measures at the joints between facilities are missing, which will easily cause

water leakage at the joints and affect the effect of water-retaining and flood prevention

[0036] ② The water-absorbing expansion bag flood prevention and water-retaining facilities are assembled from many parts, and the parts (except the water-absorbing expansion bag) are all metal prefabricated parts with a large

dead weight. The amount is large and time-consuming. After the water-retaining facility is used, its disassembly

workload is also large and time-consuming. Before

assembly and after disassembly, the anchor holes opened by the ground anchors need to be opened and repaired. , which increases the

workload and time-consuming

[0037] ③In addition, the flood control and water retaining facilities are generally used on an ideal flat and hard floor. If the ground is uneven or the floor (quality) is soft, it will directly affect the installation and fastening of the facility, resulting in the bottom surface of the fixing seat being unable to fully contact the ground. Adhere to the installation, it is easy to produce installation gaps, which will cause water to leak from the gaps, affecting the water retaining effect, and the soft floor (quality) will also cause the fixed ground anchors of the facility to be unable to be effectively anchored on the floor (quality) ), and the anchoring effect is greatly reduced, it is easy to cause the overall loosening of the facility, and it is easy to cause the overall displacement or even overturning of the facility under the

impact of a large amount of water, so that the water blocking effect of the facility is completely lost

[0038] ④ In addition, the water-absorbing swelling bag and its water-absorbing swelling agent particles used in this facility are disposable and non-reusable materials, which are

consumables. It is necessary to purchase a large amount of such

consumables according to the demand before use. Store for later use, and the storage environment must be kept dry and ventilated, so as to prevent the water-absorbing swelling bag and its water-absorbing agent particles from becoming ineffective due to

moisture. After use, it needs to be disposed of, especially the water-absorbing agent particles are chemical raw materials, which are especially necessary for disposal. Careful handling, so as not to cause environmental

pollution and ecological damage, from the input cost of the facility, its many external use conditions

restrict its use frequency (frequency) is not high, but its own production cost is relatively high, resulting in its economic bad sex

[0044] ① Before the flood control facility is put into use, a lot of preparatory work needs to be done (including location selection and excavation of the

storage tank, interior decoration of the flood control warehouse, assembly of components for the flood control panel, worm jacking device and guide structure, and installation of the electrical

system for the facility.

Layout, commissioning and operation of the overall

system), the

workload of these preparations far exceeds the workload of the above-mentioned various flood control facilities, comparable to a

small branch project, and its preparation work will last for a period of time. At the same time, the flood control facilities The ability and height of water retaining and intercepting water are also limited by the height of the flood control panel and the depth of the flood control chamber. Once the inflow of water or rainfall is huge, the incoming water will accumulate in the front water in a short time and cause the

water level to rise. When the accumulated water When the depth exceeds the height of the flood control panel (water retaining capacity), the excess incoming water will overflow from the top of the panel and submerge the area behind it, resulting in the failure of the flood control panel's water retaining effect

[0045] ②Because the flood control facilities of this item are mechanically assembled from many metal prefabricated parts, and the electrical construction content such as

electric drive system and

electric control system is mixed in it, the mechanical assembly and electrical construction are too specialized and complicated, and it is difficult for ordinary people to operate , it is necessary to send special personnel to carry out various operations and system debugging. At the same time, the post-maintenance of the flood control facilities also requires special personnel to operate, which cannot allow users to conveniently repair and operate by themselves. Users can only perform simple operations. When it comes, the facility fails to operate normally, and the user can only wait for the warranty, which will

delay the flood control work and cause unnecessary losses

[0046] ③The flood control facilities of this item are limited to the locations that have been completed in advance and have flood control warehouses. For other locations that have no or unconditional flood control warehouses but have flood control requirements, this flood control facility cannot be used

[0047] ④ There is no airtight waterproof measures and components on the

joint surface between the flood control panel and the flood control warehouse in the flood control facilities of this item. Once there is water or rainfall, it is easy to seep water downward along the

joint surface and invade the bottom of the flood control warehouse to accumulate, and There are no accumulated water drainage measures and components inside the flood control warehouse. Excessive water accumulation and excessive

moisture in the warehouse will easily cause damp failures in the electrical system, resulting in the failure of the flood control facilities to operate normally. In addition, this facility has strict requirements on the waterproof quality of the waterproof

engineering of the flood control warehouse itself. Extremely high, it must be able to

resist the long-term impact and intrusion of

groundwater and

soil water, and ensure that the warehouse is always kept dry. Otherwise, once

groundwater or

soil water invades into the flood control warehouse and forms stagnant water, it is easy to cause the electrical system to be flooded and short-circuited Serious consequences such as damage and

corrosion of metal parts will affect the normal use of the facility, and this facility lacks a fault

alarm device. When the water is serious, it is easy to cause safety hazards such as electric shocks for users

[0048] ⑤The flood control facility has a relatively high cost of use, and a large investment in early production and construction costs, and its use frequency (

utilization rate) is low because of its "adapted to local conditions (ie flood control warehouse)" use conditions, and its economic efficiency is poor. Moreover, in order to ensure the normal and long-term operation of this facility, it is necessary to prepare more spare parts and consumable parts for its maintenance. The maintenance costs and material loss also highlight its lack of economy and social resources in disguise." waste"

[0054] ①The water retaining capacity and height of the flood control

retaining wall are limited by the height of the chair-shaped vertical plate. Once the inflow of water or rainfall is huge, it is easy to cause the

water level of the chair-shaped vertical plate to rise sharply in a short period of time , although it is equipped with a PLC liquid level height monitoring component, it can only realize early warning and notification of the liquid level height. Once the water level exceeds the height of the chair plate vertical plate, the accumulated water will overflow through the chair plate vertical plate After the top surface, and submerge the area behind it, the water retaining function of the flood control

retaining wall will completely fail at this time, and the overflowing water will also affect the normal operation of the PLC liquid level monitoring components. If the PLC liquid level height monitoring Components soaked in stagnant water for a long time may easily cause component damage and other consequences

[0055] ② Although the suction cup assembly on the anti-skid part of the chair-shaped plate bottom plate of the flood control

retaining wall can play a certain role in anti-sliding and fixing, it is only used for ideal flat and dry and clean ground conditions. If the ground is uneven or there is water and oil, Then the suction cup assembly will not be able to effectively absorb with the ground and form a vacuum working state, resulting in a greatly reduced anti-slip and fixing effect of the suction cup assembly, which will affect the overall stability and working performance of the facility. In addition, even if the suction cup assembly is ideally flat and dry In terms of ground conditions, how to ensure that many suction cups in the suction cup assembly can be uniformly, reliably and evenly adsorbed on the ground without leakage and emptying occurs. This is also where this facility has not been clearly explained and has technical defects.

[0056] ③Although there are anti-slip parts and suction cup components on the bottom plate of the chair-shaped plate of the flood control retaining wall, the contact surface between the base plate itself and the ground is not completely vacuum-fit and compact. Once the flood control incoming water hits the flood control retaining wall, there will inevitably be some incoming water Seepage occurs from the contact surface between the bottom plate and the ground to form leakage water, which greatly reduces the flood control and

water retention capacity of the flood control retaining wall. In addition, leakage water will also affect the working state of the suction cup assembly, causing it to lose its vacuum after being invaded by incoming water It fits the working state, and then affects its fixing and anti-sliding performance, and finally has a greater negative impact on and reduces the anti-impact ability of the flood control retaining wall. In severe cases, it may lead to the overturning of the flood control retaining wall and the collapse of the flood control fortifications

Login to View More

Login to View More  Login to View More

Login to View More