Preparation method of p-(methylthio)benzaldehyde

A technology of p-chlorobenzaldehyde and benzaldehyde, applied in the direction of mercaptan preparation, sulfide preparation, organic chemistry, etc., can solve the problems of increased difficulty in wastewater treatment, a large amount of organic impurities, poor operating conditions, etc., and achieve high product yield, The effect of high total yield and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

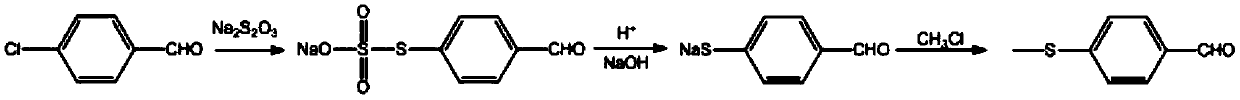

Method used

Image

Examples

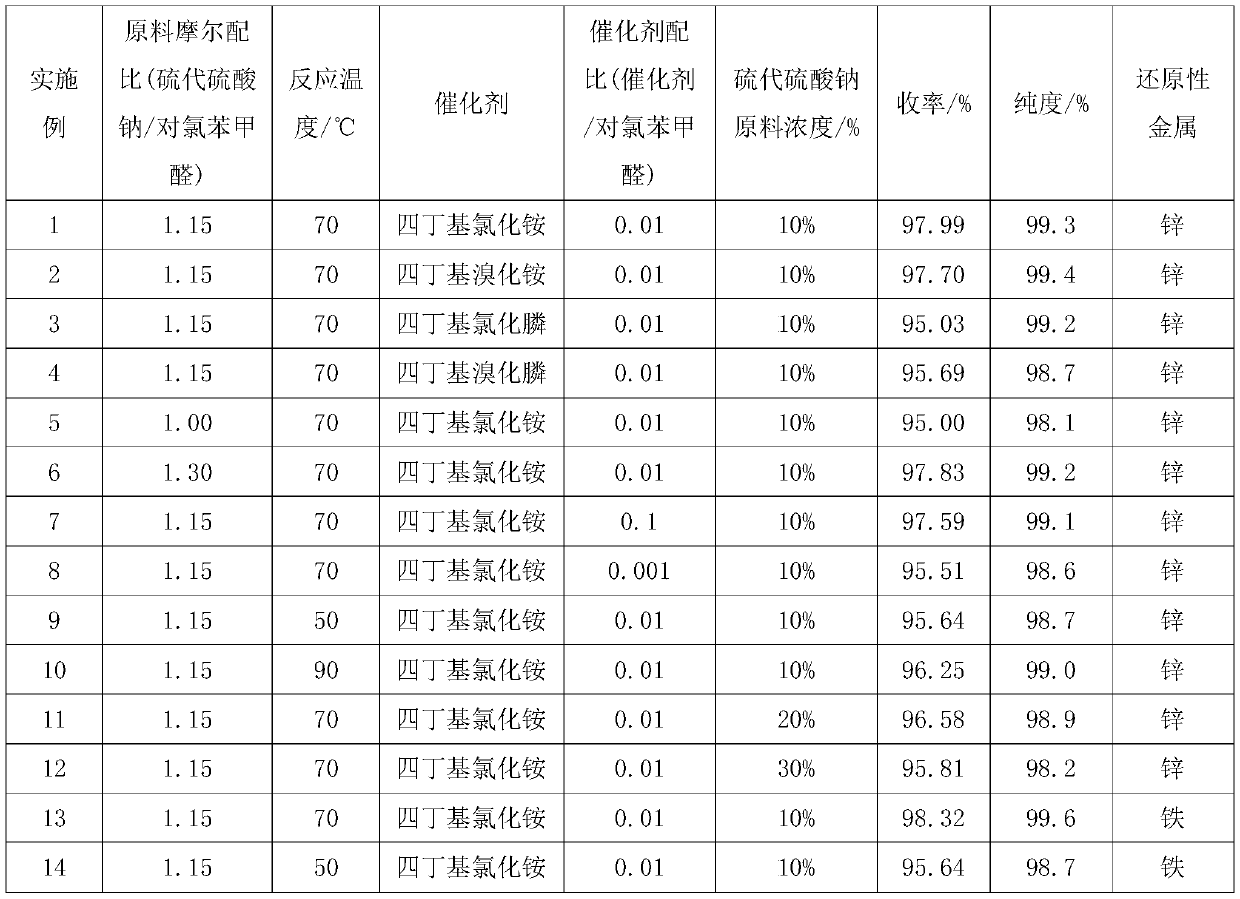

Embodiment 1

[0027] a. Take 412g (0.261mol) of 10% sodium thiosulfate solution and add it to a four-necked flask with mechanical stirring, add 0.63g (0.00227mol) tetrabutylammonium chloride, raise the temperature to 70°C, and throw in 31.95 g (0.227mol) p-chlorobenzaldehyde, reacted for 4 hours;

[0028] b. Add concentrated sulfuric acid to adjust pH=0, heat up to 90°C, and keep warm for 2 hours; then lower the temperature to 60°C, add 0.15g zinc powder, stir and keep warm for 2 hours; then add 32% liquid alkali dropwise to adjust pH=9.0, Stir for 1 hour;

[0029] c. Put the material into the autoclave, raise the temperature to 90°C, feed in methyl chloride, keep the pressure in the kettle at 0.5MPa, and keep it warm for 8 hours; after the heat preservation is over, cool it to 35°C, and put the material into the separatory funnel to stand still After 30 minutes, the lower organic phase was collected to obtain the product crude product; 31.95g sodium sulfate was added to absorb water in th...

Embodiment 2

[0031] The difference between this implementation method and Example 1 is that the phase transfer catalyst is the tetrabutylammonium bromide of 0.73g (0.00226mol), and other steps are identical, obtain 33.79g product, molar yield 97.70%, gas phase detection purity is 99.3%.

Embodiment 3

[0033] The difference between this implementation method and Example 1 is that the phase transfer catalyst is 0.67g (0.00227mol) tetrabutylphosphine chloride, other steps are the same, obtain 32.86g product, molar yield 95.03%, gas phase detection purity is 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com