Preparation method of PAMAM composite antifouling material

An anti-fouling and solution technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, biocide-containing paints, etc., can solve the problems of limited anti-fouling effect, to avoid adhesion and growth, good marine anti-fouling effect, The preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

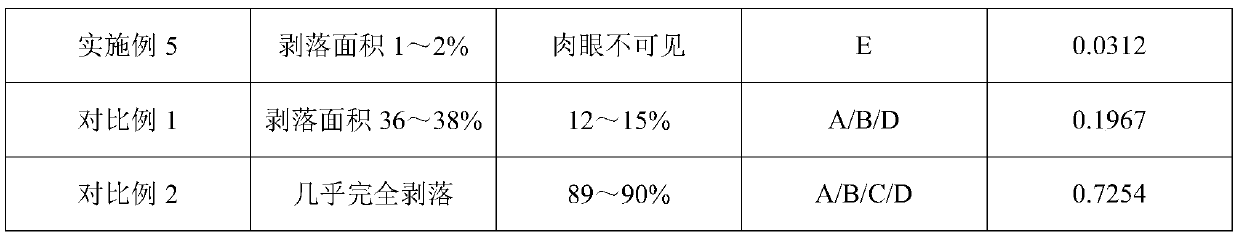

Examples

Embodiment 1

[0041] A preparation method of PAMAM composite antifouling material, said preparation method comprising the following preparation steps:

[0042] 1) Add PAMAM G4.5 to water, add sodium hydroxide for saponification reaction, and then stand at a constant temperature of 45°C for 40 minutes, then add 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 dimethyl Esterification of base siloxane and sulfonic acid, neutralize the acidity with ammonia water and react to obtain a layered liquid. The PAMAM material used and 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 di The molar ratio of methyl siloxane is 1:1;

[0043] 2) Separating the layered liquid, removing the aqueous layer solution and retaining the ester layer solution;

[0044] 3) Prepare an aqueous dispersion of activated silicon powder, place 200-mesh silicon powder in 6wt% hydrofluoric acid aqueous solution and soak for 5 minutes, then place it in piranha solution and heat to 85°C for immersion and activation for 30 minutes, then filter out the...

Embodiment 2

[0046]A preparation method of PAMAM composite antifouling material, said preparation method comprising the following preparation steps:

[0047] 1) Add PAMAM G1.5 to water, add sodium hydroxide for saponification reaction, and then stand at a constant temperature of 40°C for 30 minutes, then add 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 dimethyl Esterification with base siloxane and concentrated sulfuric acid, neutralize the acidity with ammonia water and react to obtain a layered liquid. The PAMAM material used and 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 di The molar ratio of methyl siloxane is 1:1;

[0048] 2) Separating the layered liquid, removing the aqueous layer solution and retaining the ester layer solution;

[0049] 3) Prepare an aqueous dispersion of activated silicon powder, place 200-mesh silicon powder in 8wt% hydrofluoric acid aqueous solution and soak for 5 minutes, then place it in piranha solution and heat to 85°C for immersion and activation for 30 minutes, then ...

Embodiment 3

[0051] A preparation method of PAMAM composite antifouling material, said preparation method comprising the following preparation steps:

[0052] 1) Add PAMAM G3.5 to water, add sodium hydroxide for saponification reaction, and then stand at a constant temperature of 55°C for 30 minutes, then add 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 dimethyl Esterification with base siloxane and concentrated sulfuric acid, neutralize the acidity with ammonia water and react to obtain a layered liquid. The PAMAM material used and 1,5-dihydroxy-1,1,5,5 tetraphenyl-3,3 di The molar ratio of methyl siloxane is 1:1;

[0053] 2) Separating the layered liquid, removing the aqueous layer solution and retaining the ester layer solution;

[0054] 3) Prepare an aqueous dispersion of activated silicon powder, place 200-mesh silicon powder in 6wt% hydrofluoric acid aqueous solution and soak for 5 minutes, then place it in piranha solution and heat to 85°C for immersion and activation for 30 minutes, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com