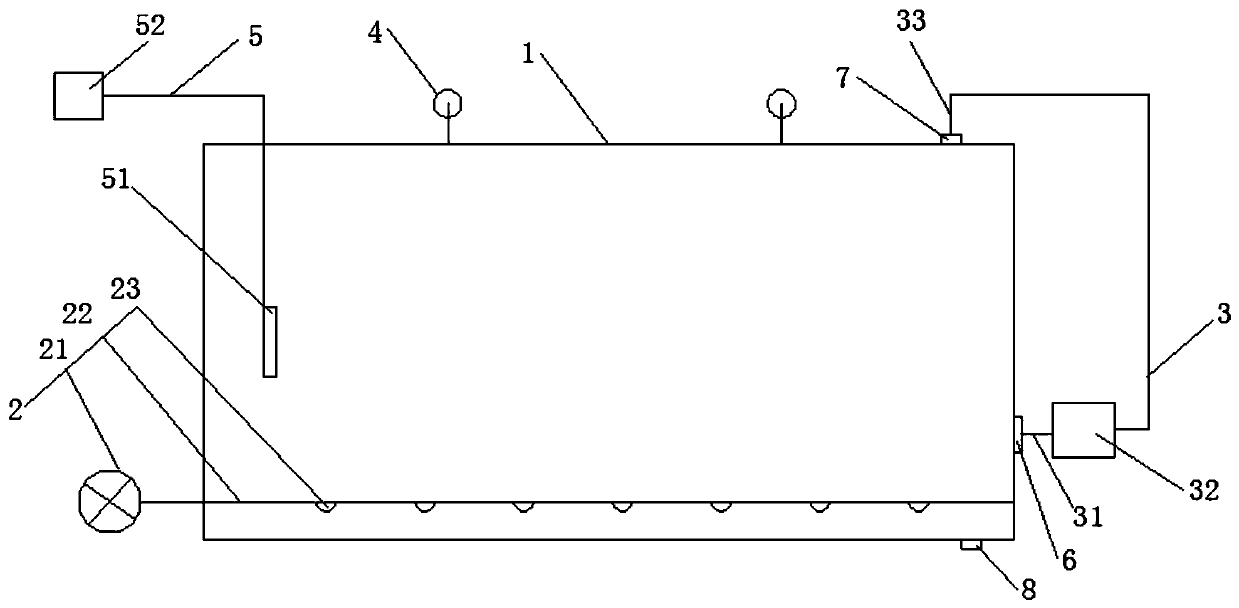

Marine algae culture device and application thereof

A cultivation device and technology for marine algae, which are applied in seaweed cultivation, application, single-cell algae, etc., can solve the problems of low light utilization rate, easy blockage of pipes, agglomeration, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

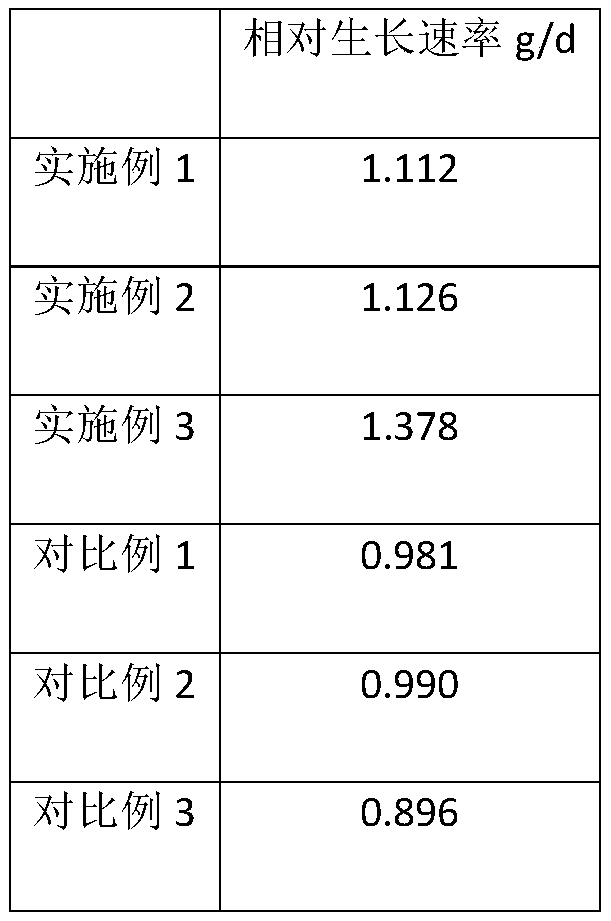

Embodiment 1

[0051] Take sargassum seedlings, soak them in 50% ethanol aqueous solution for 20 seconds and take them out to obtain algae seedlings 1; 3 The density was inoculated in the culture pool with an internal light intensity of 120 μmol m -2 ·s -1 , cultivated under the condition of water temperature of 26°C for 2 days to obtain the algae seedling 2, and the algae seedling 2 was supplemented with CO in the water body by intermittent aeration 2 The way of secondary culture, to obtain mature algae;

[0052] Among them, the gas flow rate of the intermittent aeration is 10L / min, the concentration of carbon dioxide in the gas is 600μL / L, the aeration is 2h, and the aeration is stopped for 0.5h;

[0053] During the secondary cultivation process, the light intensity was 90 μmol m -2 ·s -1 , the light time is 14h, and the water temperature is 23°C; the replacement amount of seawater per day is 1 / 8 of the total amount of seawater; every 8 days, add 2.5-4mL / L spinosad mixed solution to th...

Embodiment 2

[0055] Take the sargassum seedlings, soak them in 60% ethanol aqueous solution for 10 seconds and take them out to obtain the algae seedlings 1; 3 The density was inoculated in the culture pool with an internal light intensity of 100 μmol m -2 ·s -1 , cultivated under the condition of water temperature of 28°C for 3 days to obtain the algae seedling 2, and the algae seedling 2 was supplemented with CO in the water body by intermittent aeration 2 The way of secondary culture, to obtain mature algae;

[0056] Among them, the gas flow rate of intermittent aeration is 15L / min, the concentration of carbon dioxide in the gas is 400μL / L, aeration is 2h, and aeration is stopped for 0.5h;

[0057] During the secondary cultivation process, the light intensity was 110 μmol m -2 ·s -1 , the light time is 12h, and the water temperature is 25°C; the daily replacement amount of seawater is 1 / 10 of the total amount of seawater; every 10 days, add 4ml / L spinosad mixed solution to the backw...

Embodiment 3

[0059] Take sargassum seedlings, soak them in 55% ethanol aqueous solution for 15 seconds and take them out to obtain algae seedlings 1; pretreated algae seedlings 1, press 4.5kg / m 3 The density was inoculated in the culture pool with an internal light intensity of 110 μmol m -2 ·s -1 , and the water temperature was 27°C for 2.5 days to obtain algae seedlings 2, and the algae seedlings 2 were supplemented with CO in the water body by intermittent aeration. 2 The way of secondary culture, to obtain mature algae;

[0060] Among them, the gas flow rate of intermittent aeration is 13L / min, the concentration of carbon dioxide in the gas is 500μL / L, the aeration is 2h, and the aeration is stopped for 0.5h;

[0061] During the secondary culture, the light intensity was 100 μmol m -2 ·s -1 , the light time is 13h, and the water temperature is 24°C; the daily replacement amount of seawater is 1 / 9 of the total amount of seawater; every 9 days, 3.5ml / L spinosad mixed solution is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com