Preparation technology of cotton paper double-sided adhesive tape

A double-sided adhesive tape and preparation technology, applied in the preparation of animal glue or gelatin, papermaking, paper machine, etc., can solve the problems of increasing bonding performance and poor mechanical properties, and achieve improved bonding force and strong hydrophobicity , the effect of high bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

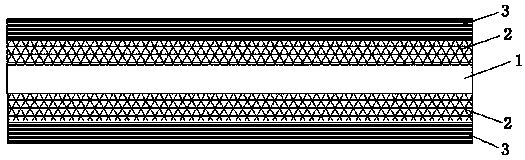

[0027] A kind of preparation technology of double-sided adhesive tape of tissue paper, this double-sided adhesive tape comprises base material 1, both surfaces of base material 1 are all coated with adhesive agent, forms adhesive agent layer 2, the other side of adhesive agent layer 2 The side is covered with release paper 3;

[0028] Wherein, substrate 1 adopts modified tissue paper, and described modified tissue paper is prepared by the following method:

[0029] S1. Add 0.5g bamboo fiber to 100mL ethanol, add 0.5-0.6g sodium hydroxide under the condition of slow stirring, then put it in a constant temperature water bath at 60℃ and stir, and add 0.5-0.6mL of 2,3-cyclo Oxypropyltrimethylammonium chloride, reacted for 2h, and repeatedly washed the product to neutrality to obtain modified bamboo fiber;

[0030] S2. Take 500mL of dimethyl sulfoxide, 1g of aramid fibers, and 1.5g of sodium hydroxide and add them into a beaker, stir magnetically at room temperature for 5-6d to ob...

Embodiment 1

[0044] Modified cotton paper is prepared by the following method:

[0045] S1. Add 0.5g of bamboo fiber to 100mL of ethanol, add 0.5g of sodium hydroxide under slow stirring conditions, then place it in a constant temperature water bath at 60°C to stir, and add 0.5mL of 2,3-epoxypropyltri Methylammonium chloride, reacted for 2h, and washed the product repeatedly to neutrality to obtain modified bamboo fiber;

[0046] S2. Take 500mL of dimethyl sulfoxide, 1g of aramid fibers, and 1.5g of sodium hydroxide into a beaker, stir magnetically at room temperature for 5 days to obtain aramid nanofiber suspension, wash with acetone for 5 times and separate, then vacuum dry at room temperature Obtain aramid fiber nanofiber powder;

[0047] S3. Add aramid nanofiber powder into distilled water to prepare a suspension with a mass fraction of 0.2%, immerse the modified bamboo fiber in the prepared suspension, ultrasonically disperse for 30 minutes, rinse with deionized water for 5 times, an...

Embodiment 2

[0050] Modified cotton paper is prepared by the following method:

[0051] S1. Add 0.5g bamboo fiber to 100mL ethanol, add 0.6g sodium hydroxide under the condition of slow stirring, then put it in a constant temperature water bath at 60℃ and stir, and add 0.6mL of 2,3-epoxypropyltri Methylammonium chloride, reacted for 2h, and washed the product repeatedly to neutrality to obtain modified bamboo fiber;

[0052] S2. Take 500mL of dimethyl sulfoxide, 1g of aramid fiber, and 1.5g of sodium hydroxide into a beaker, and stir magnetically at room temperature for 6 days to obtain aramid nanofiber suspension, which is washed with acetone for 7 times and separated, then vacuum-dried at room temperature Obtain aramid fiber nanofiber powder;

[0053] S3, adding aramid nanofiber powder into distilled water to prepare a suspension with a mass fraction of 0.2%, immersing the modified bamboo fiber in the prepared suspension, ultrasonically dispersing for 40 minutes, washing with deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com