Preparation method and application of a high-quality organic-inorganic hybrid perovskite film

A perovskite and thin film technology, applied in the field of preparation of high-quality organic-inorganic hybrid perovskite thin films, can solve the problems of fast perovskite crystallization rate, insufficient overall efficiency and stability of perovskite solar cells, etc. Achieve high device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

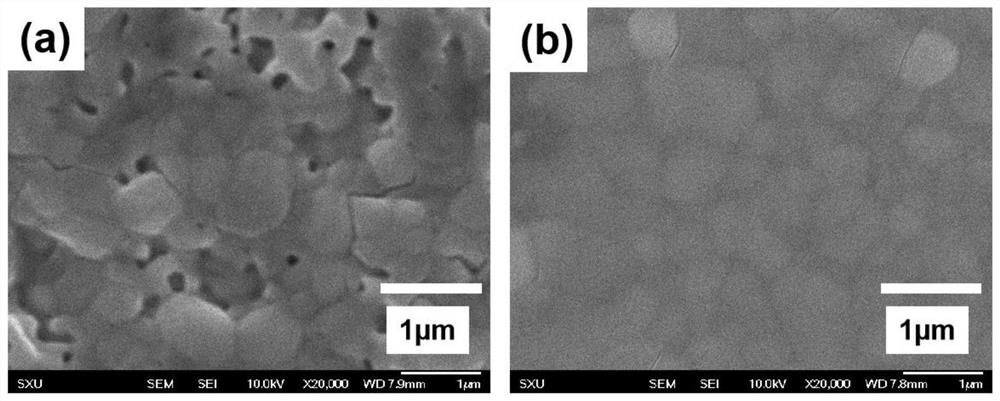

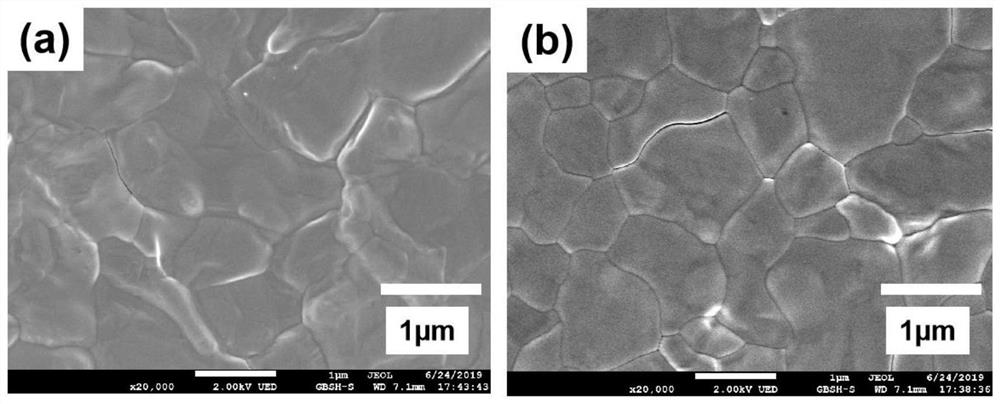

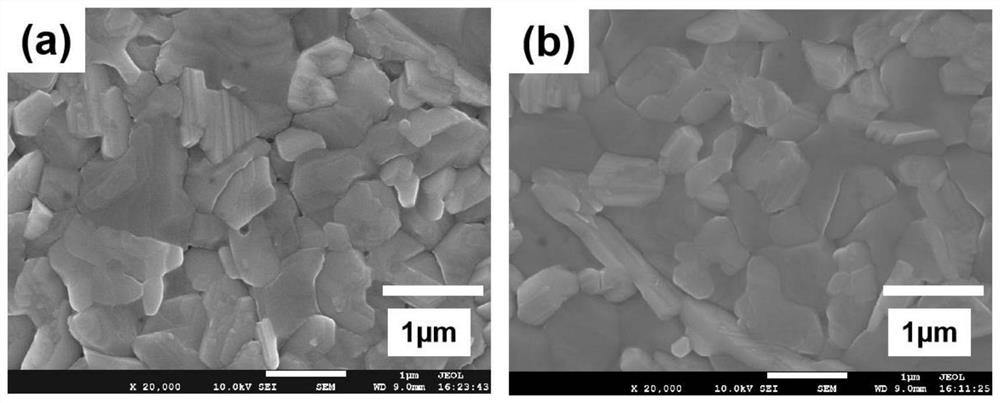

Image

Examples

Embodiment 1

[0031] A method for preparing a high-quality organic-inorganic hybrid perovskite film, comprising the steps of:

[0032] (1) Clean the indium tin oxide glass sequentially ultrasonically with detergent, distilled water, and absolute ethanol. After cleaning, place the cleaned ITO substrate in a UV-ozone cleaning machine for surface treatment for 45 minutes.

[0033] (2) Dilute the 15wt% tin dioxide aqueous solution with distilled water (the volume ratio of tin dioxide aqueous solution stock solution to distilled water is = 1:5), ultrasonically mix, and spin-coat the diluted tin dioxide aqueous solution on the ITO substrate , the spin-coating speed is 3000rpm, the spin-coating time is 30s, and annealed at 150°C for 30min to form a tin dioxide electron transport layer on the ITO substrate.

[0034] (3) In the glove box, dissolve lead iodide in N,N-dimethylformamide / dimethyl sulfoxide mixed solution (volume ratio of N,N-dimethylformamide to dimethyl sulfoxide =7:1), heated overnig...

Embodiment 2

[0041] A method for preparing a high-quality organic-inorganic hybrid perovskite film, comprising the steps of:

[0042] (1) Clean the indium tin oxide glass sequentially ultrasonically with detergent, distilled water, and absolute ethanol. After cleaning, place the cleaned ITO substrate in a UV-ozone cleaning machine for surface treatment for 45 minutes.

[0043] (2) Dilute the 15wt% tin dioxide aqueous solution with distilled water (the volume ratio of tin dioxide aqueous solution stock solution to distilled water is = 1:5), ultrasonically mix, and spin-coat the diluted tin dioxide aqueous solution on the ITO substrate , the spin-coating speed is 3000rpm, the spin-coating time is 30s, and annealed at 150°C for 30min to form a tin dioxide electron transport layer on the ITO substrate.

[0044] (3) In the glove box, dissolve lead iodide in the mixed solution of N,N-dimethylformamide / dimethyl sulfoxide (the volume of N,N-dimethylformamide and dimethyl sulfoxide Ratio = 10:1), ...

Embodiment 3

[0051] A method for preparing a high-quality organic-inorganic hybrid perovskite film, comprising the steps of:

[0052] (1) Clean the indium tin oxide glass sequentially ultrasonically with detergent, distilled water, and absolute ethanol. After cleaning, place the cleaned ITO substrate in a UV-ozone cleaning machine for surface treatment for 45 minutes.

[0053] (2) Dilute the 15wt% tin dioxide aqueous solution with distilled water (the volume ratio of tin dioxide aqueous solution stock solution to distilled water is = 1:5), ultrasonically mix, and spin-coat the diluted tin dioxide aqueous solution on the ITO substrate , the spin-coating speed is 3000rpm, the spin-coating time is 30s, and annealed at 150°C for 30min to form a tin dioxide electron transport layer on the ITO substrate.

[0054] (3) In the glove box, dissolve lead iodide (containing 5wt% cesium iodide) in N,N-dimethylformamide / dimethyl sulfoxide mixed solution (N,N-dimethylformamide and The volume ratio of dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com