Azobenzene side chain polymer energy storage material and preparation method thereof

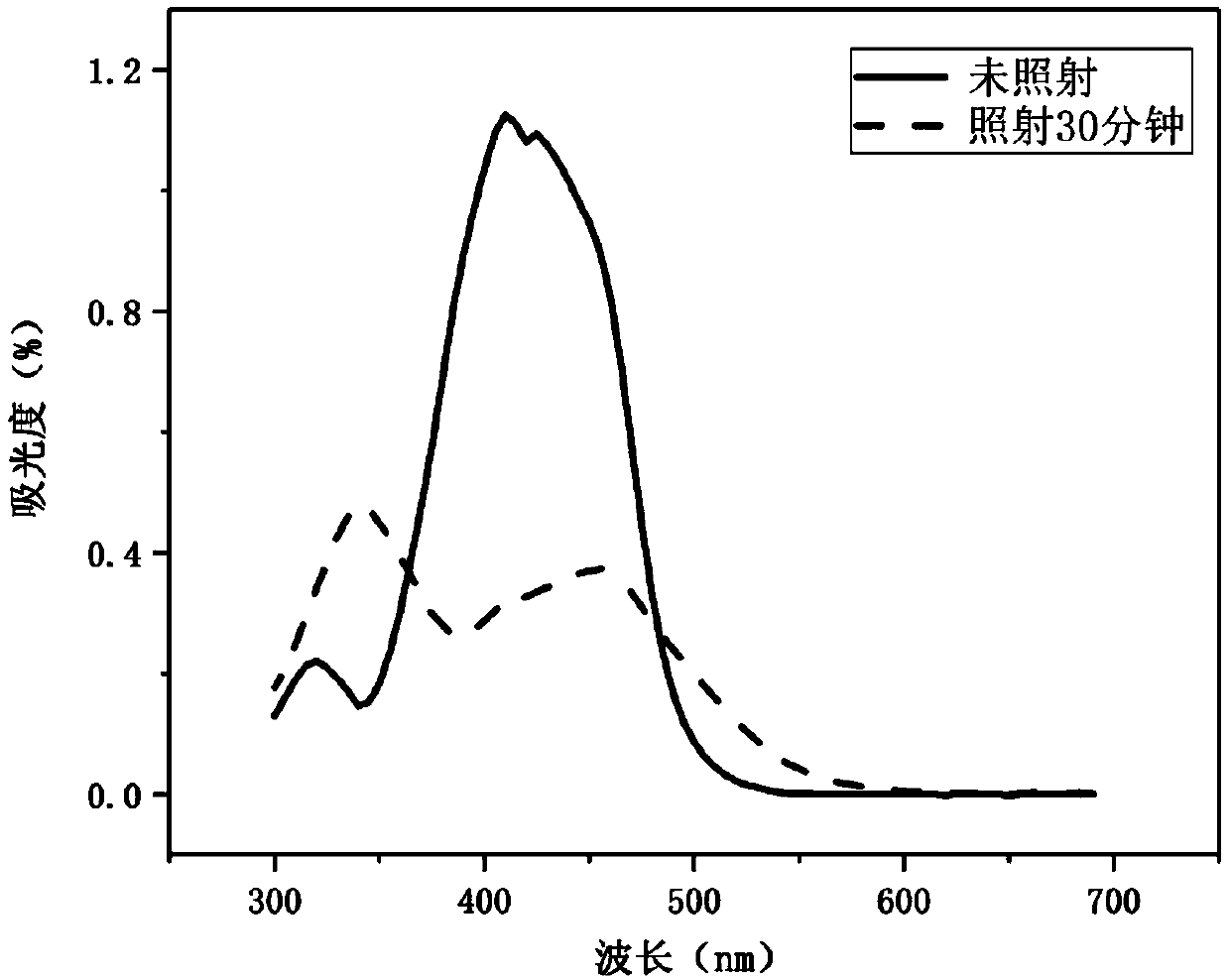

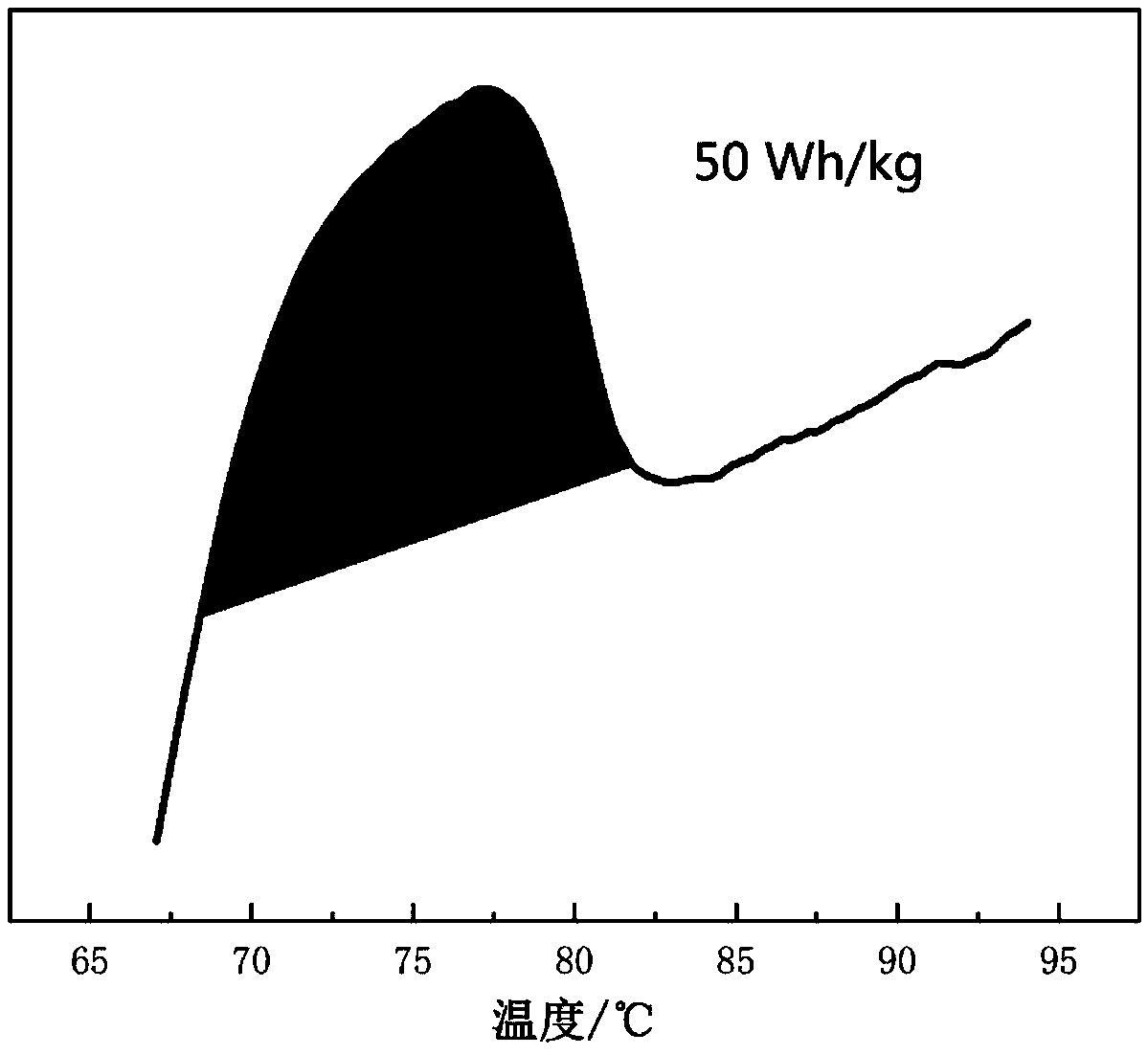

An azobenzene and polymer technology, which is applied in the field of azobenzene polymer energy storage materials and preparation, can solve the problems of low energy density and short half-life of azobenzene, and achieves high atom utilization, simple operation and flexible structure. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

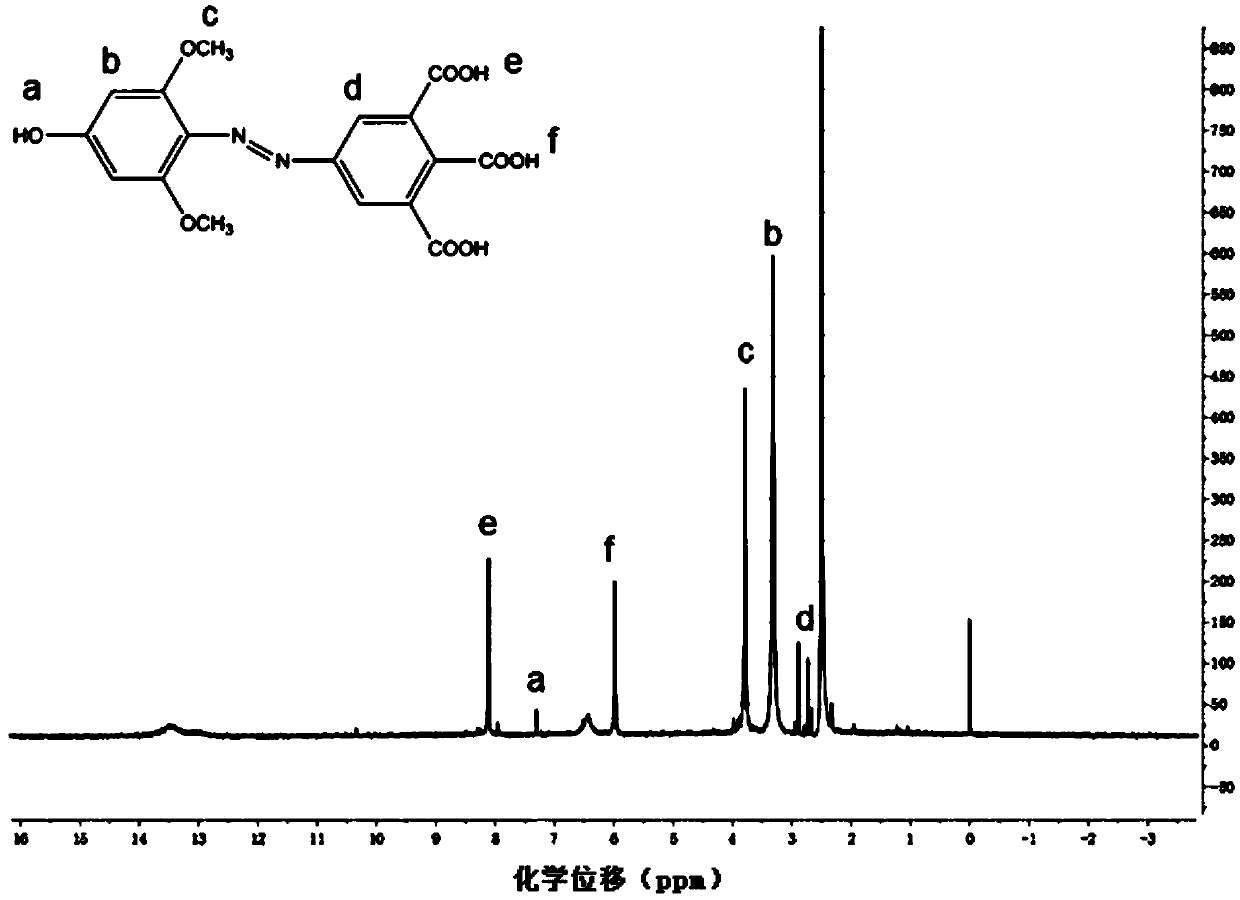

[0039] 1) The preparation of azobenzene (AZO) monomer is based on the mole of tricarboxyaniline, equivalent, 1.5 equivalents, 3 equivalents, and 4 equivalents are one time, 1.5 times, 3 times and 4 times of tricarboxyaniline.

[0040] ① 20mmol tricarboxyaniline was added to the aqueous solution in which 3 equivalents of sodium hydroxide were dissolved.

[0041] ②Dissolve an equivalent amount of sodium nitrite in water, and then add this solution dropwise to the solution in ① at 0°C under stirring conditions. After completely dissolving, add 4 equivalents of 1mol / L hydrochloric acid (that is, aqueous hydrogen chloride solution), Stirring was continued for 2 hours.

[0042] ③Under the protection of argon, 1.5 equivalents of 3,5-dimethoxyaniline was added to the solution of ②, stirred and reacted in ice bath for 5 hours, and AZO monomer was obtained.

[0043] 2) Preparation of polymer composites containing azo side chains:

[0044] ①Dissolve 20mmol of 6-amino-hexanol in concent...

Embodiment 2

[0048] 1) The preparation of AZO monomer, based on the mole of tricarboxyaniline, equivalent, 1.5 equivalent, 3 equivalent, 4 equivalent is one time, 1.5 times, 3 times and 4 times of tricarboxyaniline.

[0049] ① 25mmol of tricarboxyaniline was added to the aqueous solution in which 3 equivalents of sodium hydroxide were dissolved.

[0050] ②Dissolve an equivalent amount of sodium nitrite in water, and then add this solution dropwise to the solution in ① at 0°C under stirring conditions. After completely dissolving, add 4 equivalents of 1mol / L hydrochloric acid solution and continue stirring for 2 Hour

[0051] ③Under the protection of argon, 1.5 equivalents of 3,5-dimethoxyaniline was added to the solution of ②, stirred and reacted in ice bath for 5 hours, and AZO monomer was obtained.

[0052] 2) Preparation of polymer composites containing azo side chains:

[0053] 20 mmol of 6-amino-hexanol was dissolved in concentrated hydrobromic acid (purity: 48%, that is, the mass p...

Embodiment 3

[0057] 1) The preparation of AZO monomer, based on the mole of tricarboxyaniline, equivalent, 1.5 equivalent, 3 equivalent, 4 equivalent is one time, 1.5 times, 3 times and 4 times of tricarboxyaniline.

[0058] ①30mmol of tricarboxyaniline was added to the aqueous solution in which 3 equivalents of sodium hydroxide were dissolved.

[0059] ②Dissolve an equivalent amount of sodium nitrite in water, and then add this solution dropwise to the solution in ① at 0°C under stirring conditions. After completely dissolving, add 4 equivalents of 1mol / L hydrochloric acid solution and continue stirring for 2 Hour

[0060] ③Under the protection of argon, 1.5 equivalents of 3,5-dimethoxyaniline was added to the solution of ②, stirred and reacted in ice bath for 5 hours, and AZO monomer was obtained.

[0061] 2) Preparation of polymer composites containing azo side chains:

[0062] 30 mmol of 6-amino-hexanol was dissolved in concentrated hydrobromic acid (purity: 48%, that is, the mass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com