Treatment system and method for odor gas containing high-concentration hydrogen sulfide

A technology with high hydrogen sulfide content and treatment method, which is applied in the field of odor treatment to achieve the effects of strong operability, reducing the risk of bacterial contamination, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

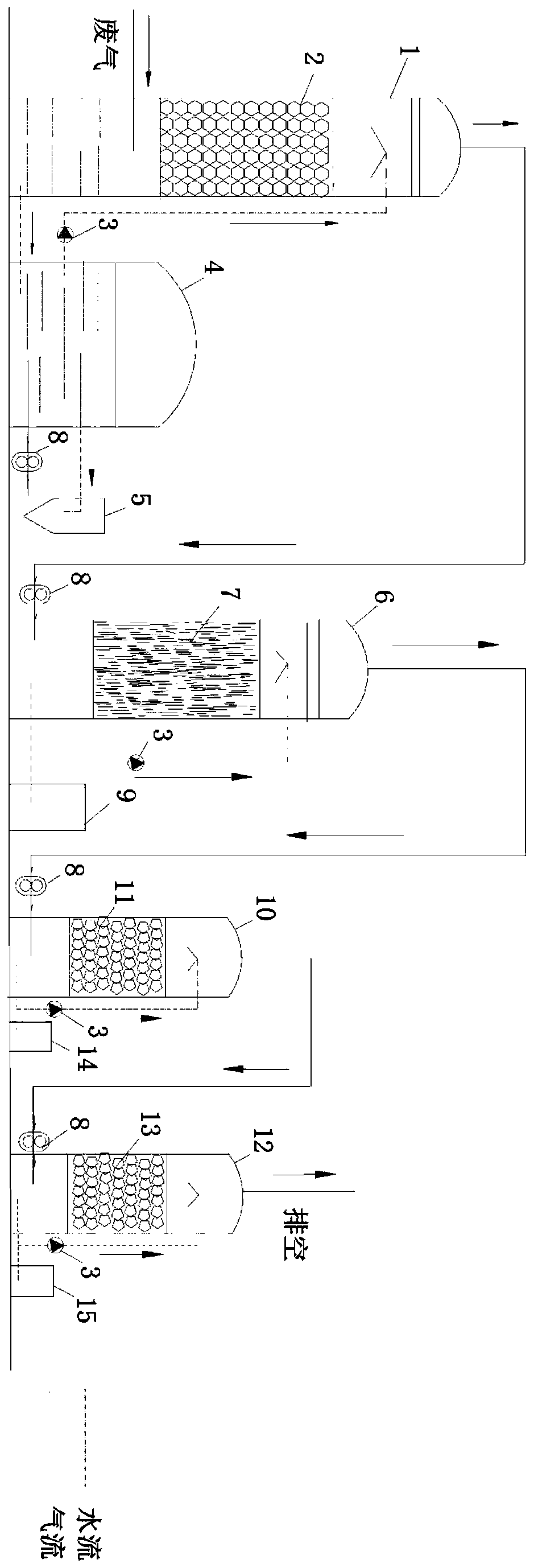

[0034] Odor volume is 10,000 m3 / h, hydrogen sulfide concentration is 8000ppm, other main components are ammonia, benzene, toluene, xylene, ethylbenzene, styrene, ethyl acetate, butyl acetate, acetone, methyl ethyl ketone , low molecular weight fatty acids, partially halogenated compounds, etc. After the odor passes through a hydrogen sulfide spray tower, the concentration of hydrogen sulfide is lower than 50ppm. After passing through 6 biological trickling filter towers, hydrogen sulfide, ammonia, and soluble VOCs have been completely removed, leaving only a small amount of hydrophobic VOCs. After the odor passes through the chemical oxidation spray tower and water washing tower, it fully meets the exhaust gas emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com