PCN metal organic framework and graphene oxide composite adsorption material and preparation method thereof

A metal-organic framework and graphene composite technology, applied in chemical instruments and methods, and other chemical processes, to achieve broad application prospects, high-efficiency uranium adsorption capacity, and short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. The preparation method of PCN metal-organic framework: take 0.05g porphyrin complexing agent (H 2 TCPP), 0.075g zirconium chloride (ZrCl 4 ), was dissolved in 8 mL of N,N-diethylformamide, and 2.7 g of benzoic acid was added as a reaction stabilizer. After the above mixed solution was ultrasonically dispersed for 0.5 h, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at a reaction temperature of 120° C. and a reaction time of 48 h. After the reaction, cool to room temperature, filter the solid matter, wash with deionized water and methanol in sequence, and dry at 80° C. for 24 hours to obtain a PCN organometallic framework.

[0033] 2. The preparation process of carboxylated graphene: ultrasonically disperse 0.5g GO in 600mL deionized water, ultrasonically disperse for 0.4h; add 5g of sodium hydroxide, ultrasonically disperse for 0.4h; add 14g of bromoacetic acid, ultrasonically disperse for 0.4h. The carboxylation reaction was carrie...

Embodiment 2

[0038] 1. The preparation method of PCN metal-organic framework: take 0.1g porphyrin complexing agent (H 2 TCPP), 0.13g zirconium chloride (ZrCl 4 ), dissolved in 15mL of N,N-diethylformamide, and added 5.5g of benzoic acid as a reaction stabilizer. After ultrasonically dispersing the above mixed solution for 0.6 h, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction. The reaction temperature was 140° C. and the reaction time was 36 h. After the reaction, cool to room temperature, filter the solid matter, wash with deionized water and methanol in sequence, and dry at 85° C. for 24 hours to obtain a PCN organometallic framework.

[0039] 2. The preparation process of carboxylated graphene: ultrasonically disperse 0.5g GO in 700mL deionized water, ultrasonically disperse for 0.5h; add 3.5g sodium hydroxide, ultrasonically disperse for 0.5h; add 10g of bromoacetic acid, ultrasonically disperse for 0.5h. The carboxylation reaction was carried out at 25...

Embodiment 3

[0044] 1. The preparation method of PCN metal-organic framework: take 0.1g porphyrin complexing agent (H 2 TCPP), 0.17g zirconium chloride (ZrCl 4 ), was dissolved in 17mL of N,N-diethylformamide, and 5.7g of benzoic acid was added as a reaction stabilizer. After ultrasonically dispersing the above mixed solution for 0.6 h, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction. The reaction temperature was 135° C. and the reaction time was 48 h. After the reaction, cool to room temperature, filter the solid matter, wash with deionized water and methanol in sequence, and dry at 75° C. for 30 h to obtain a PCN organometallic framework.

[0045] 2. The preparation process of carboxylated graphene: ultrasonically disperse 0.5g GO in 800mL deionized water, ultrasonically disperse for 0.5h; add 3.5g sodium hydroxide, ultrasonically disperse for 0.4h; add 12.5g bromoacetic acid, ultrasonically disperse for 0.4h. The carboxylation reaction was carried out at...

PUM

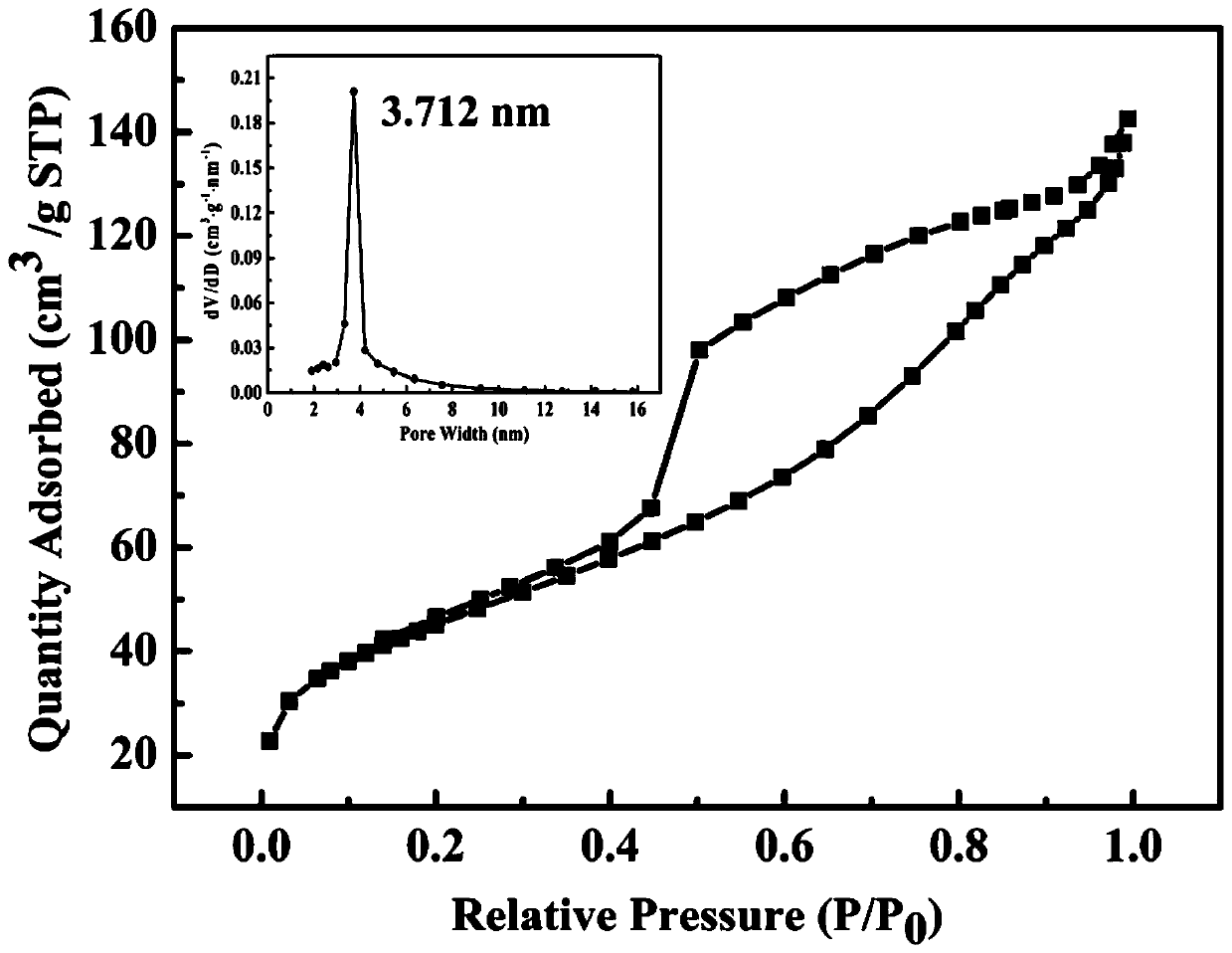

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com