Potassium-doped carbon nitride composite bismuth oxybromide photocatalysis material and preparation method thereof

A photocatalytic material, potassium hydroxide technology, applied in the field of preparation of K-g-C3N4/BiOBr photocatalyst, can solve the problems of poor adsorption of pollutants, low utilization rate of solar energy, easy recombination of photogenerated carriers, etc., and achieve improved degradation efficiency , good performance, safe and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

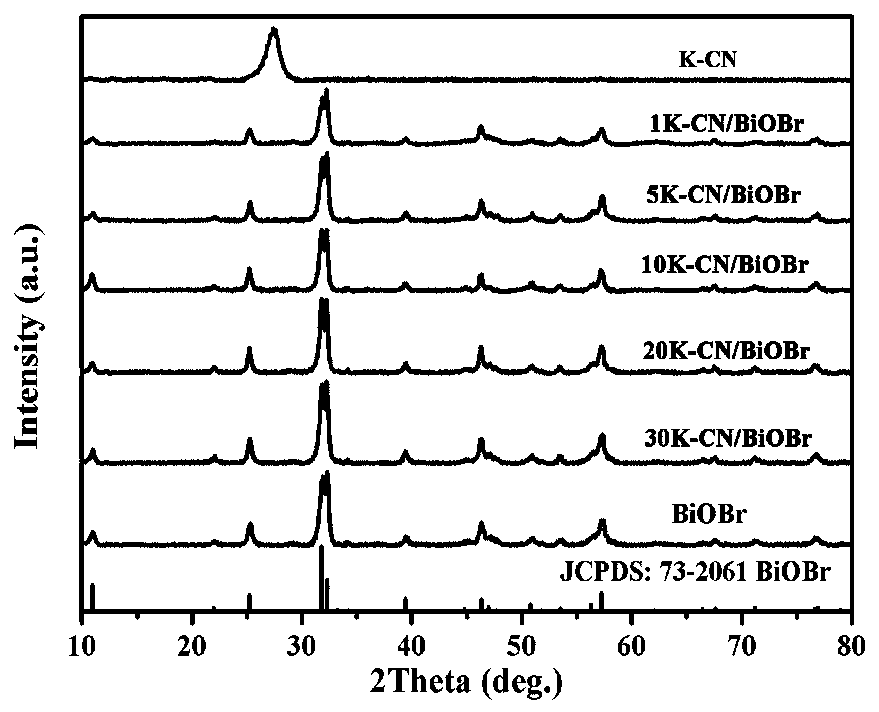

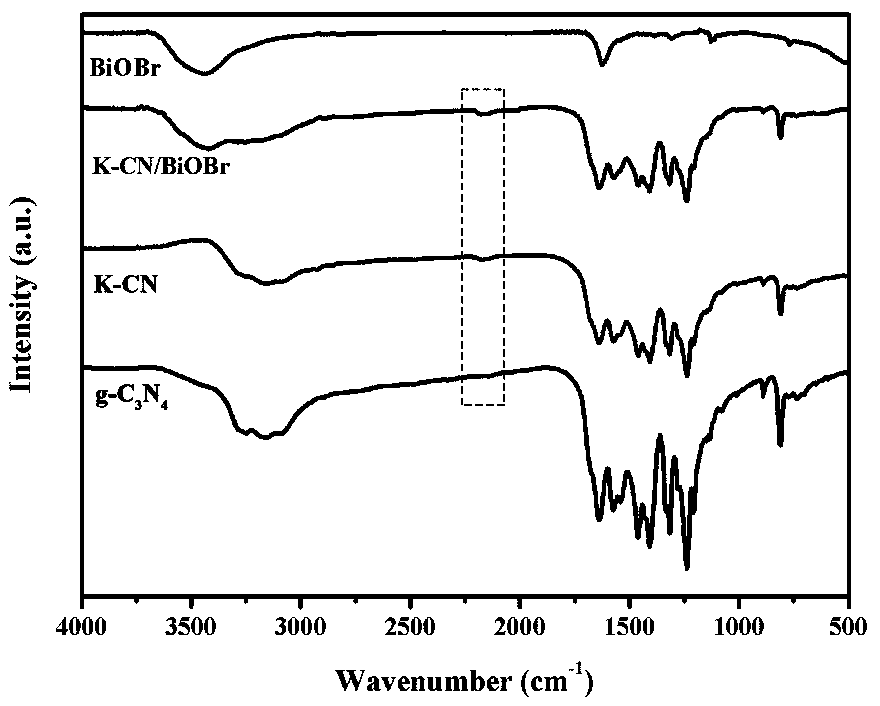

Image

Examples

Embodiment 1

[0027] (1) A certain amount of urea is ultrasonically dissolved in potassium hydroxide solution, and then the above mixed solution is dissolved at 80 o Dry in an oven at C;

[0028] (2) Calcining urea containing potassium hydroxide at a certain temperature to finally obtain yellow powder K-g-C 3 N 4 .

[0029] (3) Add K-g-C to deionized water 3 N 4 , and perform ultrasonic treatment to obtain a uniformly dispersed suspension;

[0030] (4) Add bismuth source and bromine source in the suspension of step (3), stir;

[0031] (5) Heat the suspension in step (4) in a water bath, wash and dry the reacted mixture to obtain 20K-g-C 3 N 4 / BiOBr photocatalytic material;

[0032] In the above-mentioned method, the potassium hydroxide solution concentration described in step (1) is 0.5 mol / L, and consumption is 10 mL, and the consumption of urea is 15 g.

[0033] In the above method, the calcining temperature described in step (2) is 550 o C, the calcination time is 4 h, the hea...

Embodiment 2

[0038] (1) A certain amount of urea is ultrasonically dissolved in potassium hydroxide solution, and then the above mixed solution is dissolved at 80 o Dry in an oven at C;

[0039] (2) Calcining urea containing potassium hydroxide at a certain temperature to finally obtain yellow powder K-g-C 3 N 4 .

[0040] (3) Add K-g-C to deionized water 3 N 4 , and perform ultrasonic treatment to obtain a uniformly dispersed suspension;

[0041] (4) Add bismuth source and bromine source in the suspension of step (3), stir;

[0042] (5) Heat the suspension in step (4) in a water bath, wash and dry the reacted mixture to obtain K-g-C 3 N 4 / BiOBr photocatalytic material;

[0043] In the above-mentioned method, the potassium hydroxide solution concentration described in step (1) is 0.5 mol / L, and consumption is 10 mL, and the consumption of urea is 15 g.

[0044] In the above method, the calcining temperature described in step (2) is 550 o C, the calcination time is 4 h, the heating...

Embodiment 3

[0049] (1) A certain amount of urea is ultrasonically dissolved in potassium hydroxide solution, and then the above mixed solution is dissolved at 80 o Dry in an oven at C;

[0050] (2) Calcining urea containing potassium hydroxide at a certain temperature to finally obtain yellow powder K-g-C 3 N 4 .

[0051] (3) Add K-g-C to deionized water 3 N 4 , and perform ultrasonic treatment to obtain a uniformly dispersed suspension;

[0052] (4) Add bismuth source and bromine source in the suspension of step (3), stir;

[0053] (5) Heat the suspension in step (4) in a water bath, wash and dry the reacted mixture to obtain K-g-C 3 N 4 / BiOBr photocatalytic material;

[0054] In the above-mentioned method, the potassium hydroxide solution concentration described in step (1) is 0.5 mol / L, and consumption is 10 mL, and the consumption of urea is 15 g.

[0055] In the above method, the calcining temperature described in step (2) is 550 o C, the calcination time is 4 h, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com