Method of producing nanometallic silicon powder from silicon sludge

A nano-metal silicon and silicon mud technology, applied in nanotechnology, silicon and other directions, can solve the problems of energy waste, dust and dust pollution, high energy consumption, etc., and achieve the effects of eliminating secondary pollution, reducing production costs and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

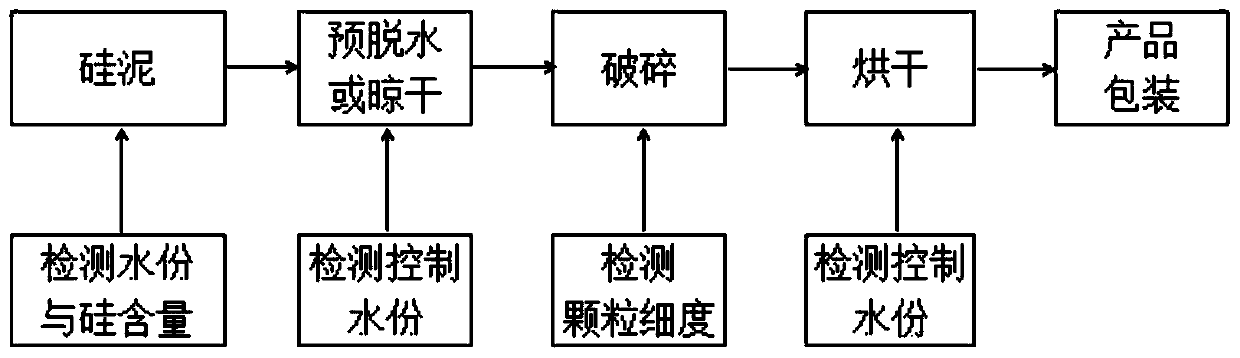

[0031] A method for producing nano-metallic silicon powder from silica mud. The raw silica mud with a water content of 25-48% is pre-dehydrated or dried, and then crushed and dried by an integrated crushing and drying equipment. Finally, the nanometer metal silicon powder is obtained by sealing and bagging.

[0032] In the process of pre-dehydration or drying, control the moisture content of silica mud at 15-35%.

[0033] During the crushing process, the particle size of the silica mud is controlled at 5.5-10.5 μm.

[0034] During the drying process, the drying temperature was controlled at 100°C.

[0035] During the drying process, ensure that the material is dried at a low ambient temperature to a moisture content of less than 1%.

Embodiment 2

[0037] A method for producing nano-metallic silicon powder from silica mud. The raw silica mud with a water content of 25-48% is pre-dehydrated or dried, and then crushed and dried by an integrated crushing and drying equipment. Finally, the nanometer metal silicon powder is obtained by sealing and bagging.

[0038] In the process of pre-dehydration or drying, control the moisture content of silica mud at 15-25%.

[0039] During the crushing process, the particle size of the silica mud is controlled at 5.5-10.5 μm.

[0040] During the drying process, the drying temperature is controlled at 115-130°C.

[0041] During the drying process, ensure that the material is dried at a low ambient temperature to a moisture content of less than 1%.

Embodiment 3

[0043] A method for producing nano-metallic silicon powder from silica mud. The raw silica mud with a water content of 25-48% is pre-dehydrated or dried, and then crushed and dried by an integrated crushing and drying equipment. Finally, the nanometer metal silicon powder is obtained by sealing and bagging.

[0044] During the pre-dehydration or drying process, the moisture content of silica mud should be controlled at 28-35%.

[0045] During the crushing process, the particle size of the silica mud is controlled at 5.5-10.5 μm.

[0046] During the drying process, the drying temperature is controlled at 110-120°C.

[0047] During the drying process, ensure that the material is dried at a low ambient temperature to a moisture content of less than 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com