Waterborne polyurethane resin for toluene reduced ultrafine fiber base and preparation method and application of waterborne polyurethane resin

A water-based, polyurethane resin technology for bass, applied in the field of polyurethane resin, can solve the problems of poor toluene resistance, unable to prepare water-based microfiber bass, etc., and achieve the effect of reducing production cost, soft and plump hand, and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

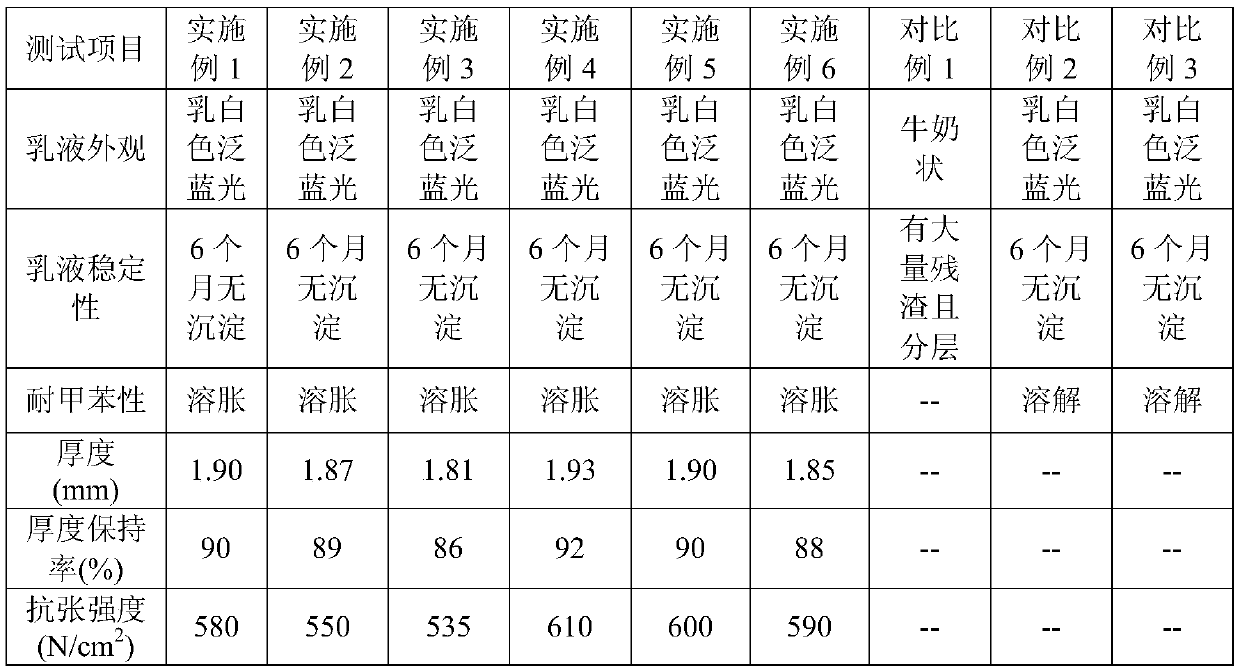

Examples

Embodiment 1

[0039] A water-based polyurethane resin for toluene-reduced superfine fiber bass provided in this example is prepared by the following method:

[0040]Add 200 grams of PTMG-2000 and 100 grams of polycarbonate diol with a molecular weight of 2000 into the reaction flask, start stirring and raise the temperature to 120°C for vacuum dehydration for 1 hour, then lower it to 55°C, add 68.7g of pure MDI and 61 grams of IPDI, keep warm at 70-95°C for 2.5 hours, then add 11.5 grams of 1.4-butanediol, keep warm for 1.5 hours, then add 16.7 grams of DMPA, keep warm for 2 hours, then measure NCO to reach the theoretical value, then cool down to 55 ℃, add 250 grams of acetone, stir for 1 hour, then add 11.5 grams of triethylamine for neutralization, transfer to an emulsification tank after 1 hour of neutralization, and cool down to 40 ℃, add 500 g of distilled water for emulsification, emulsification time is 50 minutes, emulsification After finishing, add 8.0g A95 and carry out chain exte...

Embodiment 2

[0042] A water-based polyurethane resin for toluene-reduced superfine fiber bass provided in this example is prepared by the following method:

[0043] Add 200 grams of PTMG-2000 and 100 grams of polycaprolactone diol with a molecular weight of 2000 into the reaction flask, start stirring and heat up to 120°C for vacuum dehydration for 1 hour, then drop to 55°C, add 68.7g of pure MDI and 61 Gram IPDI, keep warm at 70-95°C for 2.5 hours, then add 11.5 grams of 1.4-butanediol, continue to keep warm for 1.5 hours, then add 16.7 grams of DMPA, continue to keep warm for 2 hours, and then cool down to 55°C after passing the NCO test. Add 250 grams of acetone, stir for 1 hour, then add 11.5 grams of triethylamine for neutralization, transfer to an emulsification tank after 1 hour of neutralization, and lower the temperature to 40°C, add 500 grams of distilled water for emulsification, and the emulsification time is 40 minutes. Add 8.0g of A95 for chain extension reaction, the reactio...

Embodiment 3

[0045] A water-based polyurethane resin for toluene-reduced superfine fiber bass provided in this example is prepared by the following method:

[0046] Add 200 grams of PTMG-2000 and 100 grams of polyhexamethylene adipate diol with a molecular weight of 2000 into the reaction flask, start stirring and raise the temperature to 120°C for vacuum dehydration for 1 hour, then lower it to 55°C, and add 68.7g of Pure MDI and 61 grams of IPDI, keep warm at 70-95°C for 2.5 hours, then add 11.5 grams of 1.4-butanediol, keep warm for 1.5 hours, then add 16.7 grams of DMPA, keep warm for 2 hours, then cool down after passing the NCO test To 55°C, add 250g of acetone, stir for 1 hour, then add 11.5g of triethylamine for neutralization, transfer to an emulsification tank after 1 hour of neutralization, and cool down to 40°C, add 500g of distilled water for emulsification, and the emulsification time is 30 minutes After the emulsification is completed, add 8.0g A95 for chain extension reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com