A dual-response fluorescent sensor based on polyethyleneimine functionalized carbon quantum dots and cdtes quantum dots and its preparation method

A polyethyleneimine and fluorescent sensor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limited application and easy oxidation of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

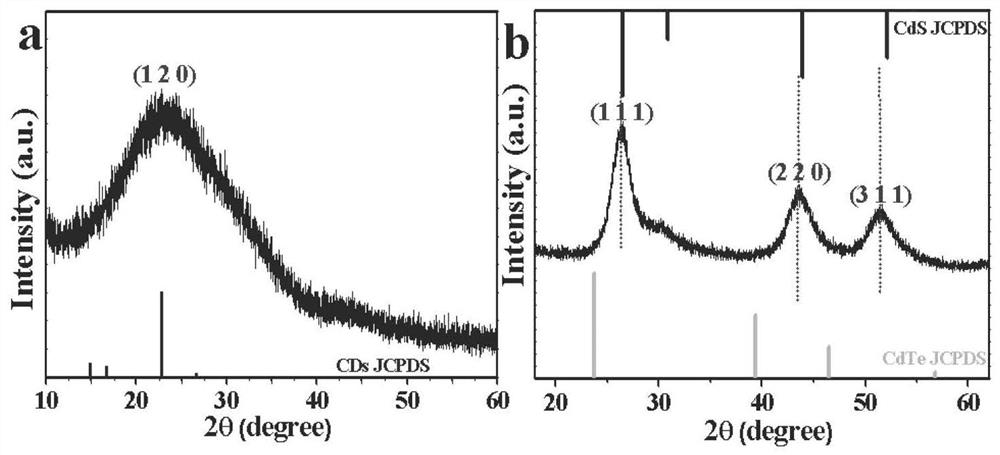

[0030] The invention provides a method for preparing a dual-response fluorescent sensor based on polyethyleneimine functionalized carbon quantum dots and CdTeS quantum dots, comprising the following steps:

[0031] Mixing the cadmium source, the organic ligand containing a mercapto functional group and water, adjusting the pH value of the system to 9-11, and injecting argon gas to obtain a cadmium source solution;

[0032] Injecting the tellurium precursor solution and the sulfur source into the cadmium source solution to obtain a mixed solution;

[0033] The mixed solution is subjected to a first hydrothermal reaction to obtain a ternary CdTeS quantum dot aqueous solution;

[0034] mixing polyethyleneimine, carbon source and water, and performing a second hydrothermal reaction to obtain a polyethyleneimine functionalized carbon quantum dot solution;

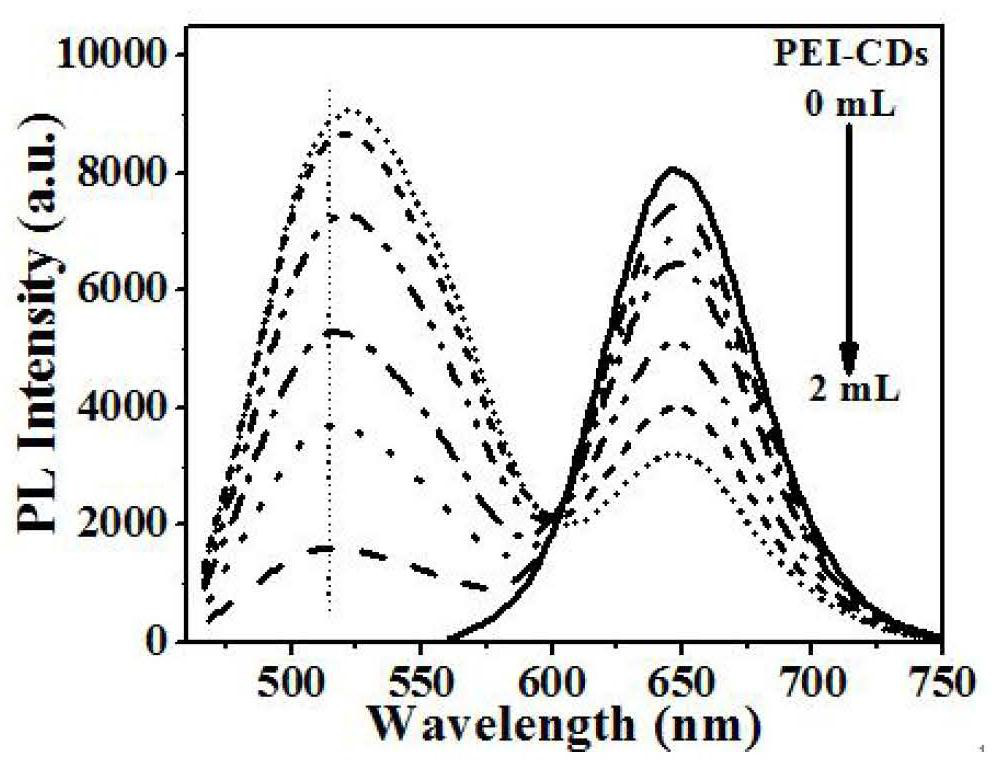

[0035] The ternary CdTeS quantum dot solution is mixed with the polyethyleneimine functionalized carbon quantum dot solution ...

Embodiment 1

[0055] Step 1: Dissolve cadmium chloride in deionized water, then add mercaptoacetic acid and stir until uniform, then adjust the pH value of the system to 9, and then pass in argon to remove the air in the mixed solution.

[0056] Step 2: Rapidly inject the tellurium precursor solution and thiourea in the ratio of 0.15:0.75 into the mixed solution obtained in Step 1 in sequence. The obtained mixed solution was transferred to a polyethylene autoclave, reacted at 180° C. for 40 minutes, and cooled naturally to room temperature to obtain a ternary CdTeS quantum dot aqueous solution.

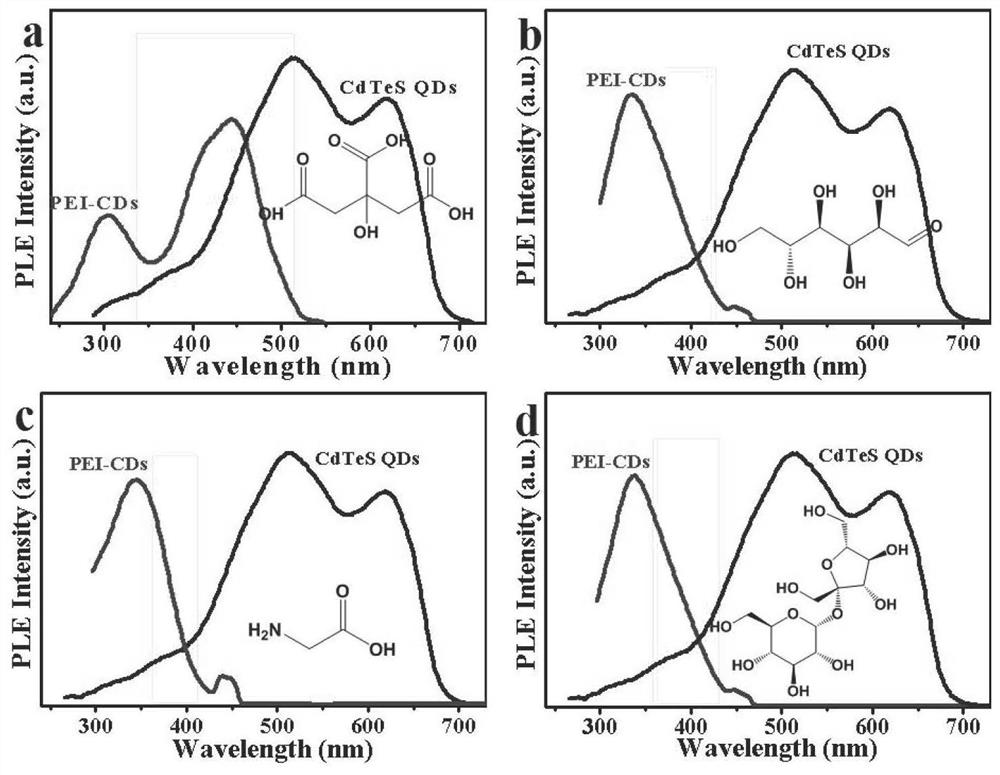

[0057] Step 3: dissolving polyethyleneimine and carbon source in deionized water, and reacting at 200° C. for 6 hours. Then, the obtained substance was dialyzed in deionized water for 15 hours to obtain a polyethylenimine functionalized carbon quantum dot solution, and the carbon sources were citric acid, glucose, glycine and sucrose respectively.

[0058] Step 4: Mix the ternary CdTeS quantum dot...

Embodiment 2

[0062] Step 1: Dissolving cadmium chloride in deionized water, then adding mercaptoacetic acid and stirring until uniform, then adjusting the pH value of the system to 10, and then introducing argon gas to remove the air in the mixed solution.

[0063] Step 2: Rapidly inject the tellurium precursor solution and thiourea in the ratio of 0.15:0.75 into the mixed solution obtained in Step 1 in sequence. The obtained mixed solution was transferred to a polyethylene autoclave, reacted at 180° C. for 40 minutes, and cooled naturally to room temperature to obtain a ternary CdTeS quantum dot aqueous solution.

[0064] Step 3: dissolving polyethyleneimine and citric acid in deionized water, and reacting at 200° C. for 6 hours. Then, the obtained substance was dialyzed in deionized water for 20 h to obtain a polyethyleneimine functionalized carbon quantum dot solution.

[0065] Step 4: Mix the ternary CdTeS quantum dot solution obtained in step 2 with the polyethyleneimine functionaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com