Thermal insulation and wear resistance modification method of lubricating oil

A lubricating oil and modification technology, applied in the field of lubricating oil, can solve problems such as difficult performance, poor thermal insulation performance, poor wear resistance, etc., to reduce friction coefficient, good thermal insulation performance, reduce adhesion and peeling layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

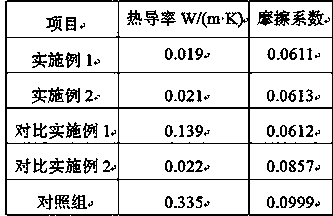

Examples

Embodiment 1

[0030] A heat-insulating and wear-resistant modification method for lubricating oil, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0031] (1) Insulation components:

[0032] Put 9 parts of pretreated aluminum silicate fiber into the mold, apply pressure to remove the air, add 4 parts of silica sol to mix, stand at 60°C to form a gel, replace water and alcohol with n-hexane solution, and then add 1 part of trimethylchlorosilane aqueous solution is subjected to hydrophobic treatment for 1 hour to obtain a composite thermal insulation component of aluminum silicate fiber-silica gel;

[0033] Among them, the pretreatment method of aluminum silicate fibers: soak 9 parts of aluminum silicate fibers in 0.01mol / L hydrochloric acid, and after ultrasonic cleaning for 30 minutes, add 1 part of KH550 aqueous solution with a mass fraction of 1% to carry out surface modification. Sexual treatment to obtain pretr...

Embodiment 2

[0042] A heat-insulating and wear-resistant modification method for lubricating oil, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0043] (1) Insulation components:

[0044] Put 11 parts of pretreated aluminum silicate fiber into the mold, apply pressure to remove air, add 6 parts of silica sol and mix, stand at 65°C to form a gel, replace water and alcohol with n-hexane solution, and then add 2 parts of trimethylchlorosilane aqueous solution were subjected to hydrophobic treatment for 2 hours to obtain a composite thermal insulation component of aluminum silicate fiber-silica gel;

[0045] Among them, the pretreatment method of aluminum silicate fibers: soak 11 parts of aluminum silicate fibers in 0.01mol / L hydrochloric acid, and after ultrasonic vibration cleaning for 40 minutes, add 2 parts of KH550 aqueous solution with a mass fraction of 1% to carry out surface modification. Sexual treatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com