Method for preparing high-sulfur-loading-mount electrode material, namely sulfur-titanium dioxide-polypyrrole (S-TiO2-PPy)

A titanium dioxide and electrode material technology, which is applied in the field of preparation of high-sulfur-loaded electrode materials, can solve the problems of easy solubility of sulfides, immature preparation methods, and large changes in sulfur volume, so as to avoid complex preparation processes and have good application prospects. , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of High Sulfur Loading Electrode Material S-TiO 2 -PPy method comprising the following steps:

[0026] Step 1: After mixing 100mL of isopropanol and 5mL of butyl titanate, stir it with a magnet to form a uniform mixed solution, then put a certain amount of 0.25g of BC cut into small pieces into it and soak for 2 days to obtain BC air condensation glue;

[0027] Step 2: After mixing 90mL of isopropanol and 10mL of water, stir it with a magnet to form a uniform aqueous solution of isopropanol. Rinse the BC soaked in step 1 with isopropanol quickly twice, and immerse in the prepared isopropanol In the aqueous solution, magnetically stirred for 0.5h and left to stand for 3 days, then freeze-dried, and kept at 500°C for 6h under air atmosphere to obtain a three-dimensional TiO with a tube wall thickness of about 8-15nm. 2 nanotube;

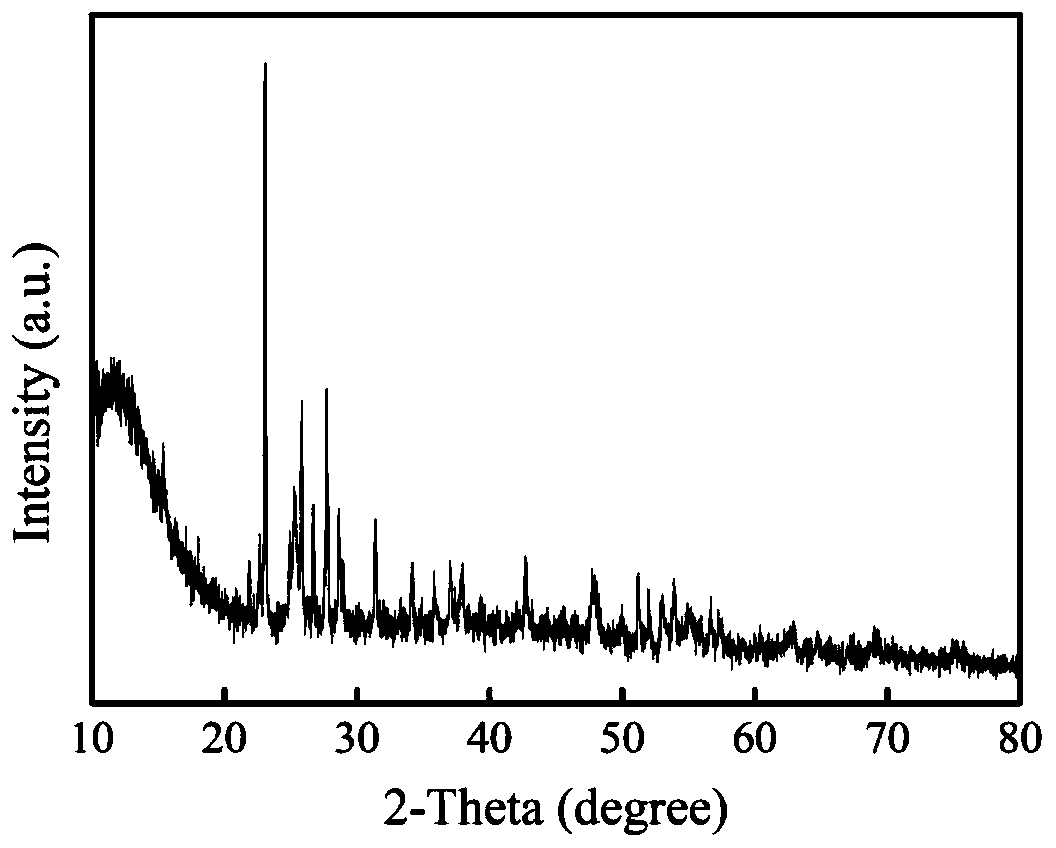

[0028] Step 3: Dissolve 0.3g of elemental sulfur in 5mL of CS 2 , and then 0.1g of the three-dimensional TiO synthesized in ste...

Embodiment 2

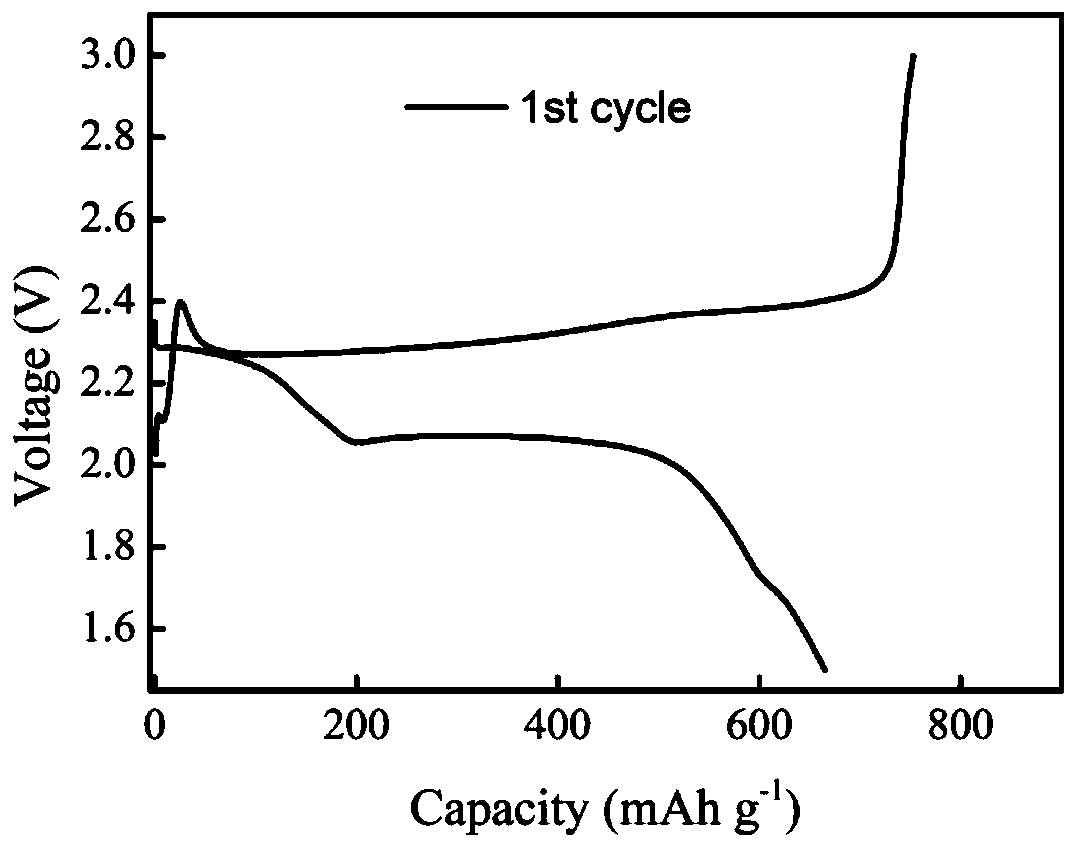

[0032] A Preparation of High Sulfur Loading Electrode Material S-TiO 2 -The method of PPy, in embodiment 2, except that step one is different from the step in embodiment 1, other steps are all the same. In step 1, adjust the volume of isopropanol and butyl titanate to 100mL of isopropanol and 3mL of butyl titanate, and the obtained three-dimensional TiO 2 The wall thickness of the nanotube is about 15-30nm, and the final S-TiO 2 -PPy as Figure 4 and Figure 5 As shown, the S-TiO obtained in Example 2 2 - The first charge and discharge diagram of PPy is as follows Figure 6 shown.

Embodiment 3

[0034] A Preparation of High Sulfur Loading Electrode Material S-TiO 2 -The method of PPy, in embodiment 3, except step one is different from the step in embodiment 1, other steps are all the same. In step 1, adjust the volume of isopropanol and butyl titanate to 100mL of isopropanol and 7mL of butyl titanate, and the obtained three-dimensional TiO 2 The wall thickness of the nanotube is about 35-50nm, and the final S-TiO 2 -PPy as Figure 7 and Figure 8 As shown, the S-TiO obtained in Example 3 2 - The first charge and discharge diagram of PPy is as follows Figure 9 shown.

[0035] In summary, the preparation method of the present invention is to grow a layer of TiO on the surface of BC 2 , the removal of BC by high-temperature sintering yielded three-dimensional TiO 2 nanotubes, and then 3D TiO by impregnation method 2 Elemental sulfur is injected into the nanotubes, and then a layer of PPy is coated on the surface of the electrode material to obtain an electrode m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com