Orange peel antiskid coating and preparation method thereof

An anti-skid coating and orange pattern technology, applied in the coating field, can solve the problems of poor wear resistance, weather resistance, slip resistance, etc., and achieve the effect of improving scratch resistance, increasing hardness and wear resistance, and obvious three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

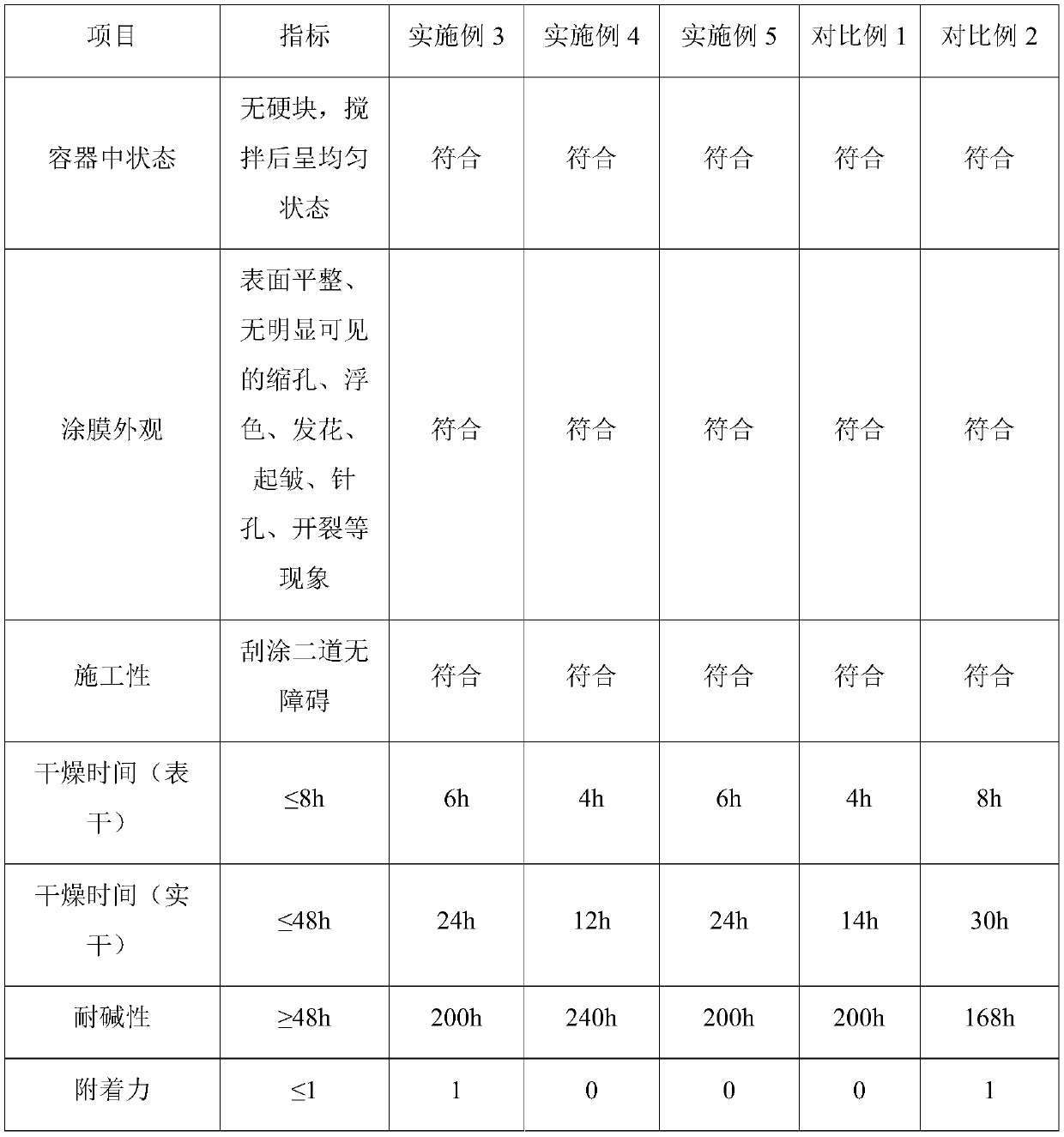

Examples

Embodiment 1

[0040] An embodiment of the present invention provides an orange pattern anti-slip coating, which includes the following raw material components in mass percentage: organic fluorine modified epoxy resin 15%, phenolic resin 7%, active diluent 3%, dispersant 0.5%, bentonite 2.0% , fumed silica 0.5%, titanium dioxide 5.0%, heavy calcium carbonate 18.4%, dolomite powder 30%, talc powder 8%, defoamer 0.1%, substrate wetting agent 0.2%, anti-oil leveling agent 0.3 % and curing agent 10%.

[0041]Wherein, the phenolic resin is produced by Suzhou Fulu Biotechnology Co., Ltd.; the reactive diluent is AGE; the dispersant is EFKA-4010 of Efka; the bentonite is 806 organic bentonite; Silicon is the AE200 of Desaigu; the titanium dioxide is the R706 of Dupont; the mesh number of the ground calcium carbonate is 800 mesh; the mesh number of the dolomite powder is 325 mesh; the mesh number of the talcum powder is 400 The defoamer is the EFKA-2722 of Efka; the substrate wetting agent is the E...

Embodiment 2

[0048] An embodiment of the present invention provides an orange pattern anti-slip coating, which includes the following raw material components in mass percentage: 30% organic fluorine-modified epoxy resin, 4% phenolic resin, 1% reactive diluent, 0.2% dispersant, and 1.0% bentonite , fumed silica 1.0%, titanium dioxide 4%, heavy calcium carbonate 15%, dolomite powder 22.6%, talc powder 5%, defoamer 0.5%, substrate wetting agent 0.5%, anti-oil leveling agent 0.2 % and curing agent 15%.

[0049] The grades of the above-mentioned components and the preparation steps of the orange pattern anti-skid coating are the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0051] The embodiment of the present invention provides an orange pattern anti-slip coating, which includes the following raw material components in mass percentage: 25.8% of organic fluorine modified epoxy resin, 6% of phenolic resin, 5% of reactive diluent, 0.6% of dispersant, and 1.5% of bentonite , fumed silica 1.5%, titanium dioxide 1.0%, heavy calcium carbonate 20%, dolomite powder 20%, talc powder 10%, defoamer 0.3%, substrate wetting agent 0.1%, oil-resistant leveling agent 0.2 % and curing agent 8%.

[0052] The grades of the above-mentioned components and the preparation steps of the orange pattern anti-skid coating are the same as those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com