Preparation method of calcium oxide with high specific surface area

A high specific surface area, calcium oxide technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problems of poor water absorption effect and small specific surface area, and achieve strong hygroscopicity, The effect of large specific surface area and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

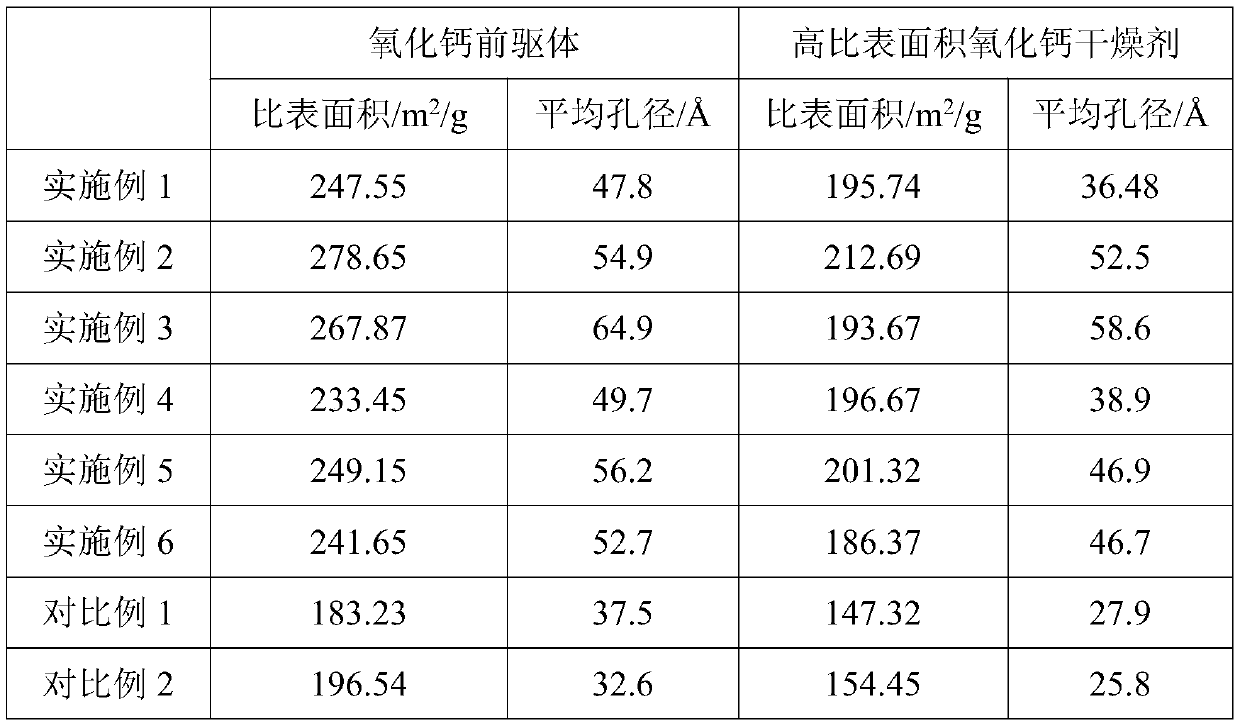

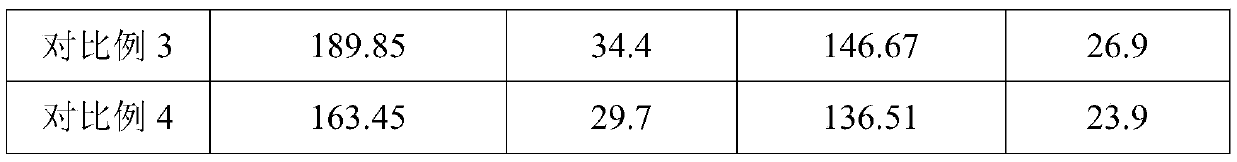

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a calcium oxide desiccant with a high specific surface area, which specifically includes the following steps:

[0028] (1) Weigh 28.3g calcium nitrate tetrahydrate and dissolve it in 1.2L distilled water to obtain a calcium nitrate solution; weigh 30.3g monohydrate citric acid and dissolve it in 1.44L distilled water. After the monohydrate citric acid is completely dissolved, the lemon Slowly add the acid solution into the calcium nitrate solution, and pay attention to stirring during the dropping process so that the two solutions are mixed evenly. After the dropwise addition is completed, the initial pH of the mixed solution is <1, and concentrated ammonia water is added dropwise to the mixed solution to adjust the pH value to 3;

[0029] (2) Evaporating and concentrating the mixed solution in a water bath at 70°C until the mixed solution is viscous and colloidal;

[0030] (3) When the mixed solution is in the form of a ...

Embodiment 2

[0036] This embodiment provides a method for preparing a calcium oxide desiccant with a high specific surface area, which specifically includes the following steps:

[0037] (1) Weigh 28.3g calcium nitrate tetrahydrate and dissolve it in 0.5L distilled water; weigh 8.65g urea and dissolve it in 0.5L distilled water. After the urea is completely dissolved, slowly add the urea solution dropwise into the calcium nitrate solution. Pay attention to stirring in the middle, and the two solutions are mixed evenly. After the dropwise addition, the initial pH of the mixed solution is <1, and an appropriate amount of concentrated ammonia water is added dropwise to the mixed solution to adjust the pH value to 2;

[0038] (2) Evaporate and concentrate the mixed solution in a water bath at 60°C until the mixed solution is in the form of a viscous colloid;

[0039] (3) When the mixed solution is in the form of a viscous colloid, move it to a vacuum drying oven and dry at 100°C to form a xer...

Embodiment 3

[0045](1) Weigh 28.3g calcium nitrate tetrahydrate and dissolve it in 0.5L distilled water; weigh 10.78g glycine and dissolve it in 0.5L distilled water. After the glycine is completely dissolved, slowly drop the glycine solution into the calcium nitrate solution with a dropping funnel , pay attention to stirring during the dropwise addition, so that the two solutions are mixed evenly. After the dropwise addition is completed, the initial pH of the mixed solution is <1, and at this time, an appropriate amount of concentrated ammonia water is added dropwise to the mixed solution to adjust the pH value to 4;

[0046] (2) Evaporating and concentrating the mixed solution in a water bath at 80°C until the mixed solution is viscous and colloidal;

[0047] (3) When the mixed solution is in the form of a viscous colloid, move it to a vacuum drying oven and dry at 105°C to form a xerogel;

[0048] (4) Place the dry gel in a muffle furnace, and bake it at 220°C for 55 minutes under a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com