Downward automatic welding method of gas-shielded alkaline flux-cored wire for long-distance pipeline

A welding method and technology of flux-cored welding wire, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of insufficient refinement of metal grain structure, thick single welding seam thickness, and reduction of post-heating times, etc. Achieve the effects of excellent mechanical properties, high impact performance of welds, and reduction of welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

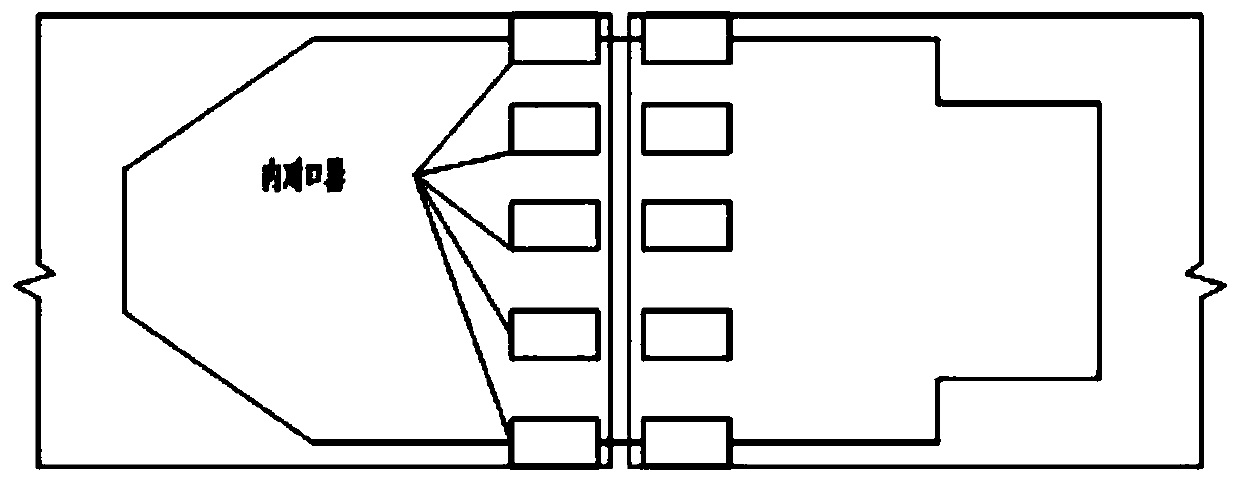

[0039] Nozzle group pair: the nozzle group pair uses an inner mouthpiece (such as figure 1 ), the blunt edge of the groove is 1.5mm, and the pairing gap is 1.0mm. Groove processing uses an internal expansion beveling machine for pipe mouth processing.

[0040] The downward automatic welding is preferably carried out with a single torch external welding machine. The single torch external welding machine has flat external characteristics and the drop rate of the current and voltage curves is not more than 5%. The welding cable is 50 square millimeters and the length is 25 meters. .

[0041] Filling and capping welding material: basic gas shielded flux cored wire, Φ1.2mm, basic flux cored wire includes the following components in mass fraction: CaF 2 25%, CaO 40%, SiO 2 20% and TiO 2 10%, Potassium Carbonate 2%, Sodium Carbonate 3%, the average value of welding wire deposited metal is 3.3mL / 100g measured by mercury method and chromatography; pure CO 2 The flow rate is 30L / mi...

Embodiment 2

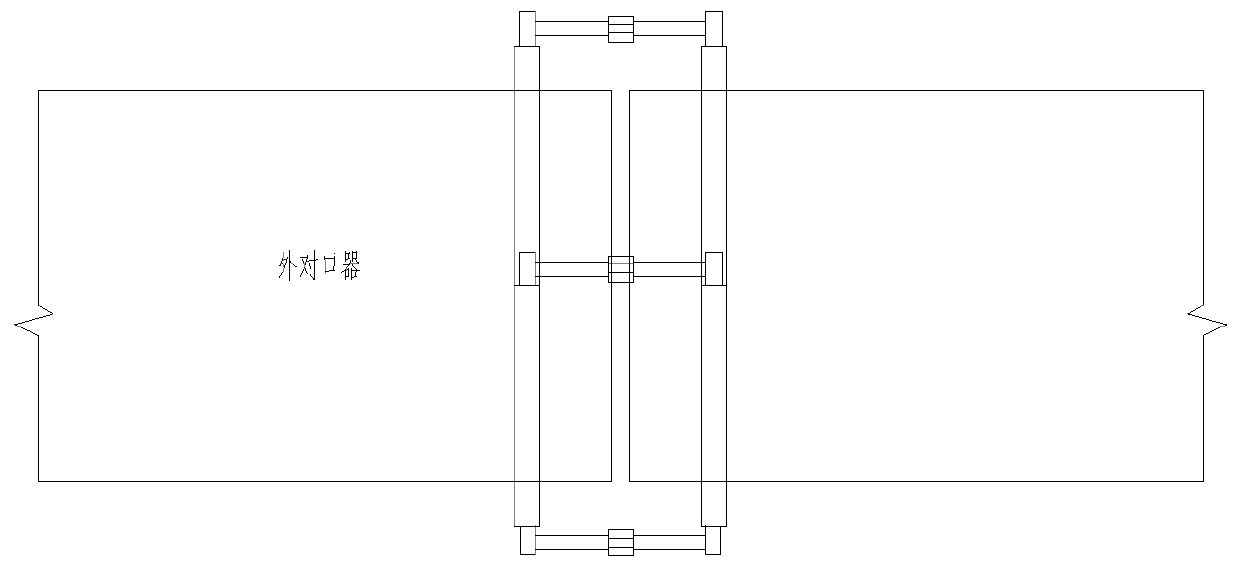

[0049] Nozzle group pair: the nozzle group pair uses external mouthpieces (such as figure 2 ), the blunt edge of the groove is 2mm, and the pair gap is 2mm. Groove processing uses an internal expansion beveling machine for pipe mouth processing.

[0050] The downward automatic welding is preferably carried out with a single torch external welding machine. The single torch external welding machine has flat external characteristics and the drop rate of the current and voltage curves is not greater than 5%. The welding cable is 75 square millimeters and the length is 35 meters. .

[0051] Filling and capping welding material: basic gas shielded flux cored wire, Φ1.2mm, basic flux cored wire includes the following components in mass fraction: CaF 2 25%, CaO 30%, SiO 2 20% and TiO 2 20%, potassium carbonate 3%, sodium carbonate 2%, the average value of welding wire deposited metal is 3.2mL / 100g measured by mercury method and chromatography; pure CO 2 The flow rate is 21L / min....

Embodiment 3

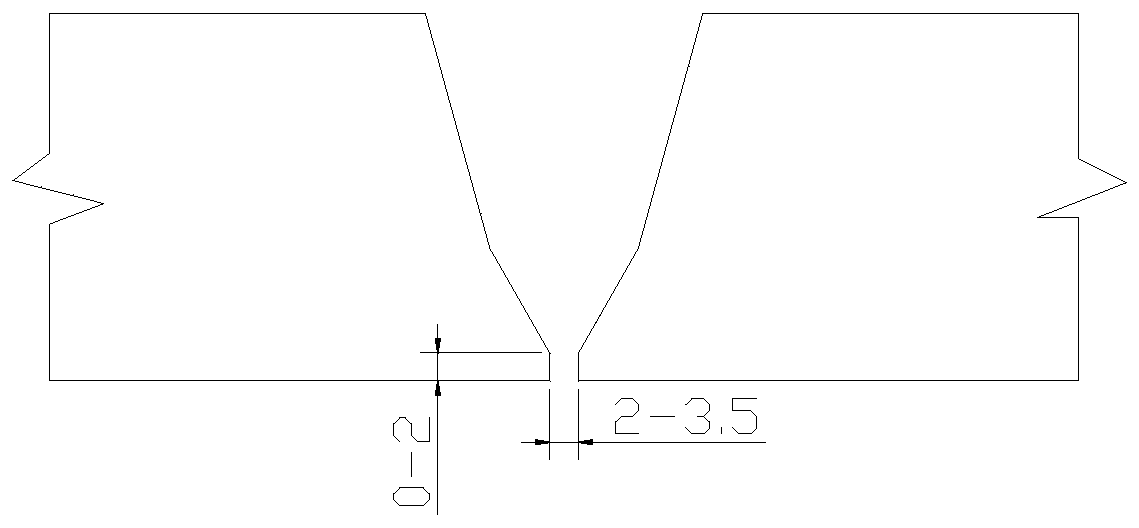

[0058] Nozzle group pair: the connecting pipe material has a pipe weld (such as image 3 ), grind the weld until the base metal is flush, and the grinding length is 100mm, and the right and wrong sides are 10% of the wall thickness and evenly distributed along the perimeter. Groove processing uses an internal expansion beveling machine for pipe mouth processing.

[0059] The downward automatic welding is preferably carried out with a single torch external welding machine. The single torch external welding machine has flat external characteristics and the drop rate of the current and voltage curves is not greater than 5%. The welding cable is 50 square millimeters and the length is 20 meters. .

[0060] Filling and capping welding material: basic gas shielded flux cored wire, Φ1.2mm, basic flux cored wire includes the following components in mass fraction: CaF 2 35%, CaO 25%, SiO 2 25% and TiO 2 10%, potassium carbonate 1%, sodium carbonate 4%, the average value of welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com