Method and system for heat supply network water supplementing treatment

A treatment system and water replenishment technology, applied in the field of industrial water treatment, can solve the problems of the body and supporting equipment occupying a large area, high operating costs, and large land occupation, achieving low inlet water quality requirements, high degree of automation, and reduced floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

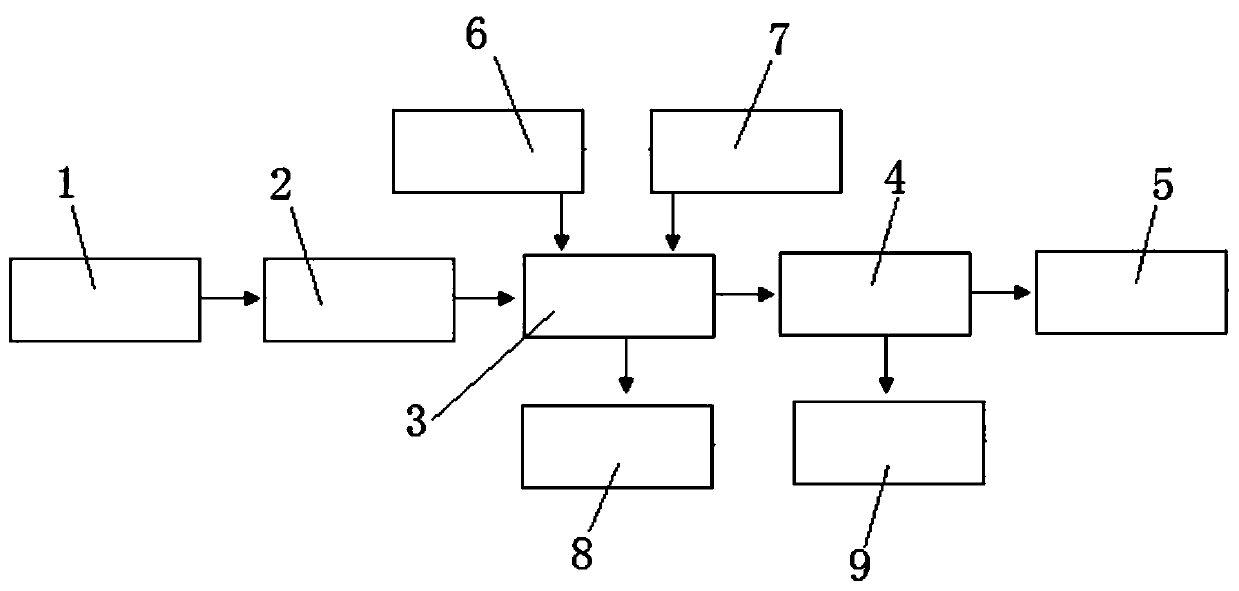

[0015] The present invention is used for the treatment system of heating net replenishment treatment method, as figure 1 As shown, it includes tap water supply pipeline, No. 1 water tank 1, filter 3, electric adsorption device 4, No. 2 water tank 5, air compressor 6, backwash pump 7, No. 1 underground pool 8, and No. 2 underground pool 9. The electric adsorption device 4 is provided with a water outlet and a flushing drain, and the filter 3 is provided with an air inlet, a backwashing water inlet and a flushing drain. The tap water supply pipeline is connected to the No. 1 water tank 1, the No. 1 water tank is connected to the filter 3 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com